Full-rigid-connection orthogonal laminated wood coupled shear wall based on steel plate constraint

A technology of glued wood and shear wall, applied in the direction of building types, buildings, building components, etc., can solve the problems of easy splitting and damage of screw hole wood, small residual deformation after earthquake, and high degree of assembly, so as to improve the transverse grain Splitting damage, convenient construction, high degree of assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

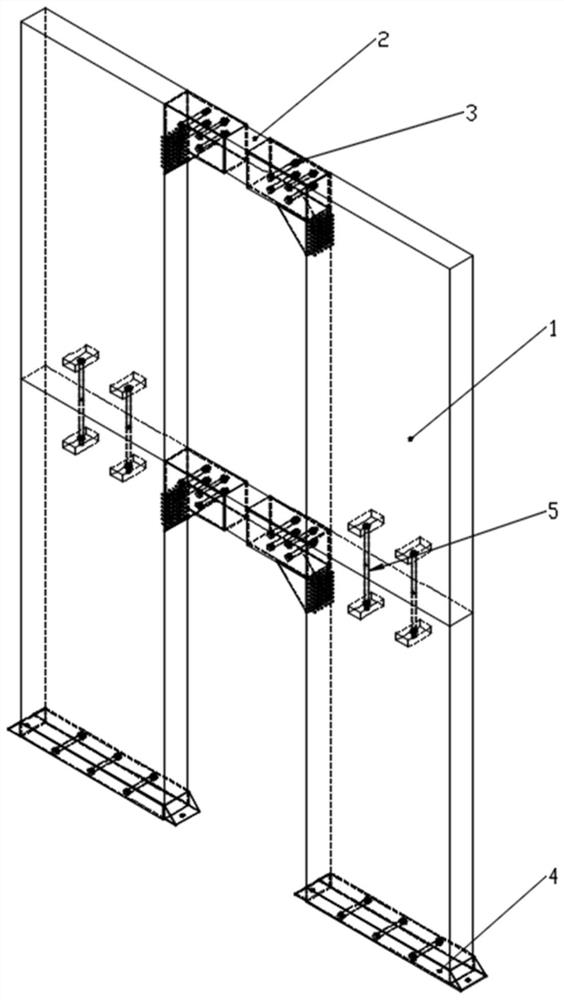

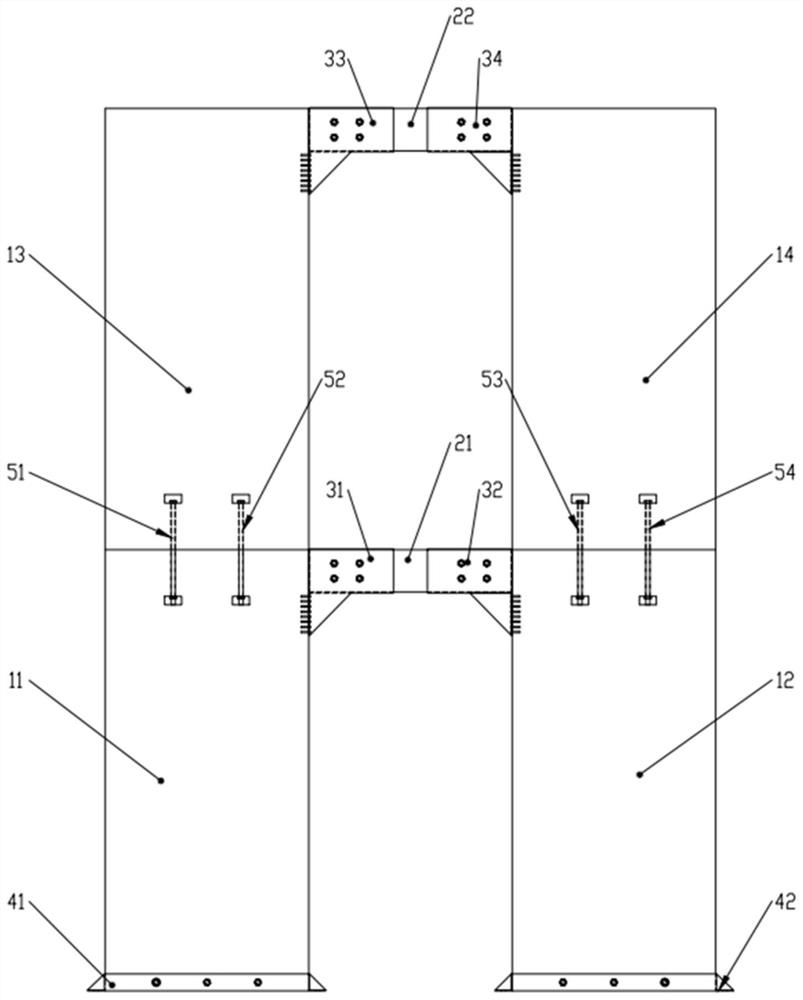

[0042] Combined with the above structure description, the shear wall of this embodiment is made. The shear wall is used in the two-story cross-glued wood structure, the floor height is 2.6m, the total height is 5.2m, the total length of the double-leg shear wall is 3600mm, and the thickness is 195mm; The length of the wall plinth is 1200mm, the length of the connecting beam is 1200mm, the cross-sectional size of the connecting beam is 175mm×250mm, and there is a gap of 5mm between the connecting beam and the wall pier to prevent the secondary stress caused by the expansion of the wood. Made of 250mm cross-laminated wood, 4 bolt holes with a diameter of 24mm are pre-opened at each end.

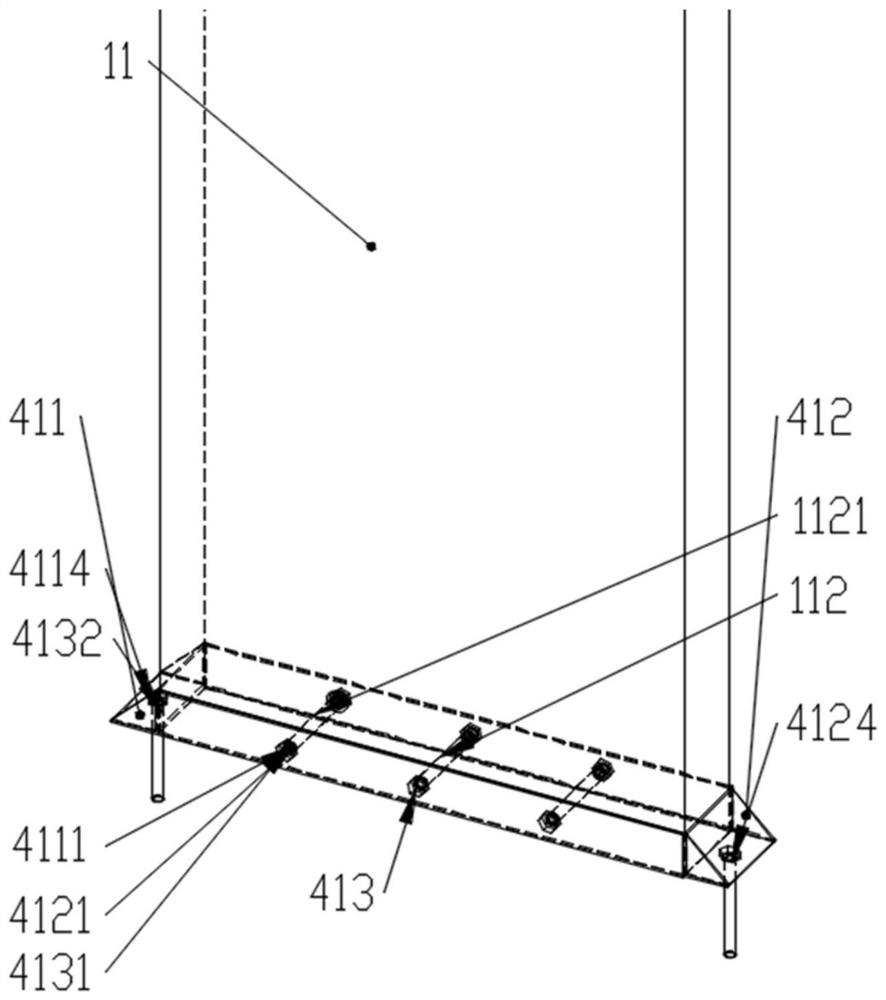

[0043] The cross-laminated timber wall limbs are prefabricated in the factory. Bolt holes with a diameter of 24mm are pre-opened at the bottom of the first-story shear wall, and two 100mm×50mm square holes are opened at the upper part 300mm from the top surface. The second-story shear wall Two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com