Washing device for textile printing and dyeing cloth

A textile printing and dyeing and washing device technology, which is applied in the processing of textile materials, equipment configuration for processing textile materials, textiles and papermaking, etc., can solve the problems of a large amount of clear water, reduce production efficiency, and affect the quality of textiles, so as to reduce water consumption, High-efficiency cleaning and thorough cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

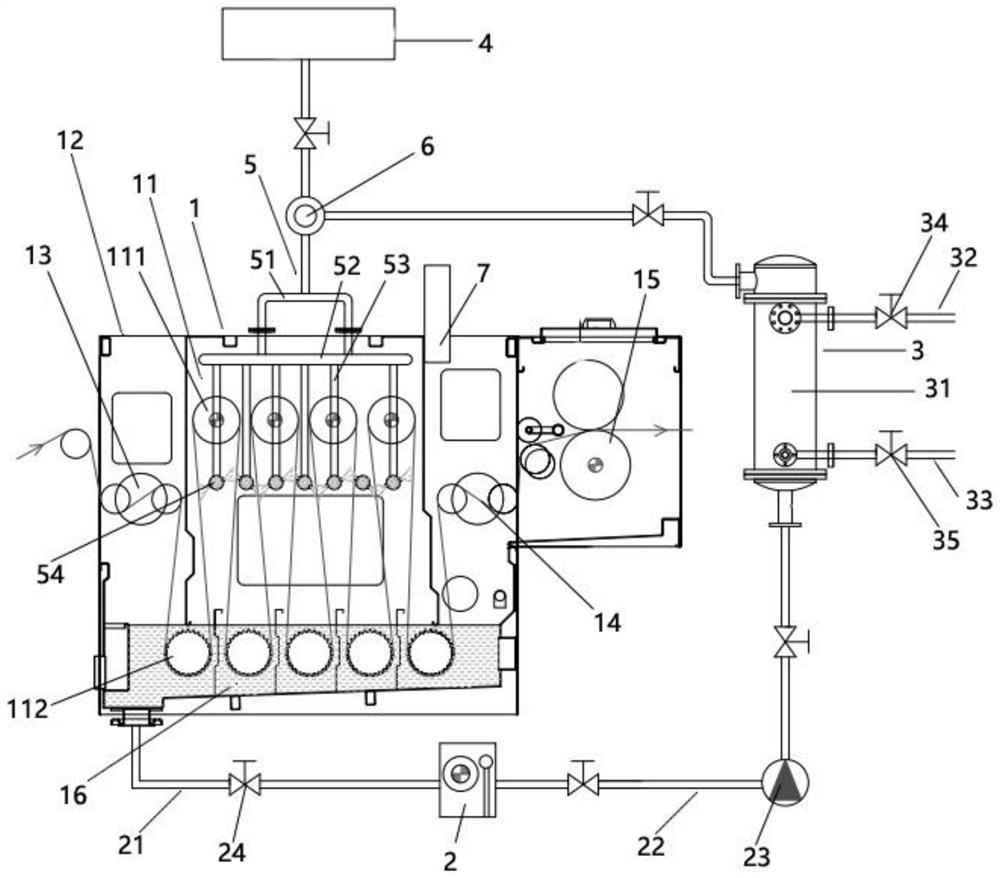

[0036] Such as figure 1 As shown, the washing device of the textile printing and dyeing cloth includes:

[0037] Cleaning device 1 is provided with cleaning water for cleaning the passing cloth;

[0038] A filter device 2, the water inlet end of the filter device 2 is connected to the cleaning water in the cleaning device 1, so as to filter the cleaning water;

[0039] The heating device 3 is connected to the water outlet of the filtering device 2, so as to heat the cleaning water entering the heating device 3;

[0040] The air compressor 4 is connected to the heating device 3, so that there is compressed air in the cleaning water. At this time, the compressed air is mixed with hot water to remove the slurry and impurities in the cloth fibers;

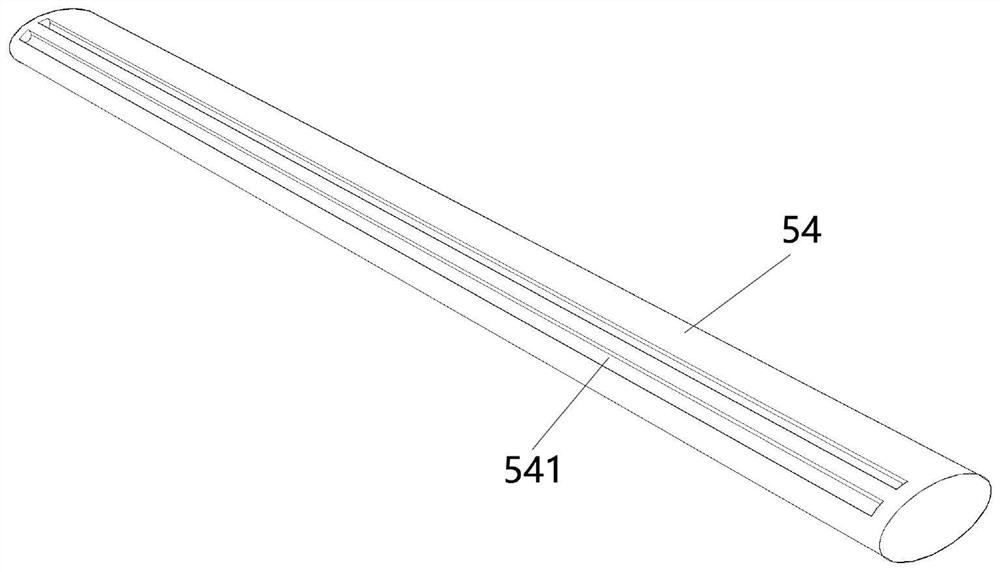

[0041] Spraying device 5, described spraying device 5 is provided with inlet water vapor pipe 51, the total water vapor pipe 52 that communicates with described inlet water vapor pipe 51 and the sub-water vapor pipe 53 that communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com