Coating liquid with high barrier property and application thereof

A high-barrier, coating liquid technology, applied in coatings, polyester coatings, etc., can solve problems such as few applications, and achieve the effects of hydrophobicity, elimination of adsorption, and high barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

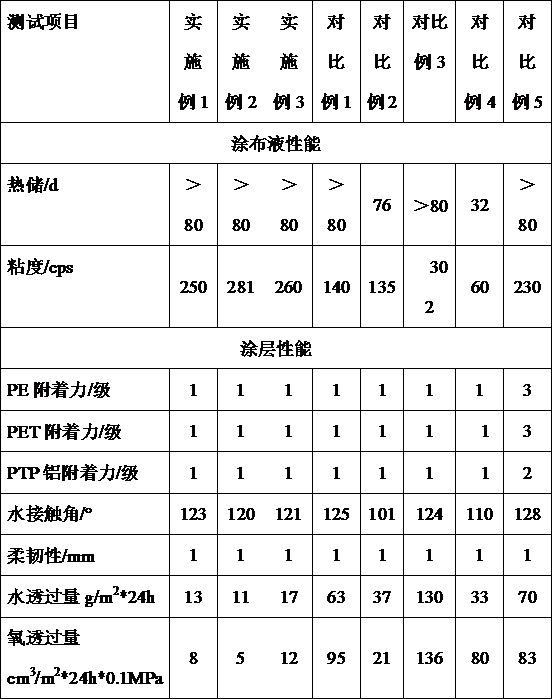

Examples

Embodiment 1

[0025] Preparation of water-based polyester emulsion

[0026] 50 parts of water-based crystalline polyester (hydroxyl value 5 mg KOH / g, number average molecular weight 15,000) prepared by polymerization of isophthalic acid, 1,6-hexanediol and isobenzenesulfonate, 14 parts of isopropanol, deionized 35 parts of water, 1 part of emulsifier ER10, stirred evenly at 300~500RPM, and kept at 60°C for 5 hours to obtain a water-based polyester emulsion;

[0027] Preparation of coating solution

[0028] Take 40 parts of the prepared aqueous polyester emulsion, 8 parts of talc powder, 10 parts of nano-silica dispersion, 0.5 part of stabilizer nano-cellulose, 0.5 part of dispersant D-193 (purchased from BYK), 30 parts of deionized water put into the reaction kettle, disperse and stir for 4 hours at a constant temperature of 60°C and at a speed of 2000~3000RPM;

[0029] After cooling to room temperature, add 5 parts of curing agent XP-2655 (purchased from Covestro), and stir at 300-500 RP...

Embodiment 2

[0031] Compared with Example 1, the difference is that the water-based crystalline resin is prepared by polymerization of a mixture of isophthalic acid and azelaic acid, trimethylolpropane, and m-benzenesulfonate (hydroxyl value 5 mg KOH / g, number average molecular weight 25000); the amount of nucleating agent mica powder in the preparation of the coating solution is 10 parts.

Embodiment 3

[0033] Compared with Example 1, the difference is that the water-based crystalline resin is made of azelaic acid, 1,2 propylene glycol, and m-benzenesulfonate (hydroxyl value 10 mg KOH / g, number average molecular weight 10,000); solidification during the preparation of the coating solution The dosage of the agent is 10 parts, and the dosage of the nucleating agent kaolin in the coating liquid preparation is 10 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com