High-adaptability cable paint spraying device

An adaptable, cable-based technology, applied in the field of painting, can solve the problems of reducing production efficiency, waste, and poor paint drying effect, and achieve the effects of uniform heating, improved drying quality, and accelerated evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

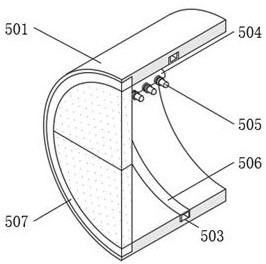

[0046] The specific implementation method is: the pressure intensity in the third fixed drum 601 gradually increases, under the action of the pressure, the one-way valve 803 is automatically opened, and the high-temperature and high-humidity air in the third fixed drum 601 enters through the return pipe 801 into the In the second fixed drum 501 , the moisture-absorbing cotton sheet 507 also drives the second branch pipe 504 and the decontamination nozzle 505 on the second branch pipe 504 to move in a circle with the cable as the center axis.

[0047] Specifically, such as Figure 5 As shown, the opposite surfaces of the linkage tooth plate 608 and the linkage tooth shaft 607 are engaged with each other, and the top of the piston seat 609 is fixedly connected with a piston rod 611, and the top of the piston rod 611 is fixedly connected with the top of the hydraulic cylinder 614 through a bridge-shaped connection seat 613 , the bottom of the hydraulic cylinder 614 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com