Organic solvent-based coating composition for coating surface of metal substrate to increase coefficient of friction of surface of said metal substrate

A metal substrate, organic solvent technology, used in anti-corrosion coatings, coatings, etc., can solve problems such as damage to the surface decoration properties and/or functional properties of metal substrates, achieve high friction coefficient, effective anti-corrosion protection, good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

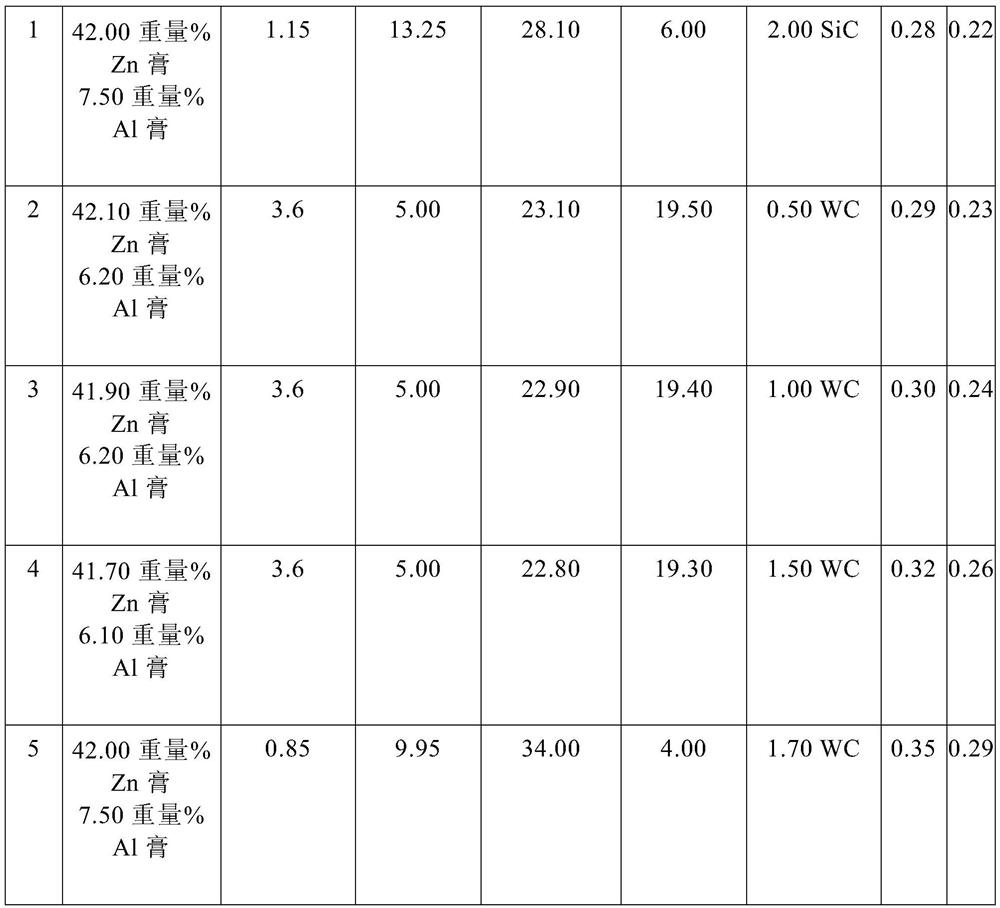

[0168] The following non-limiting examples are provided to illustrate embodiments of the invention and to facilitate understanding of the invention but are not intended to limit the scope of the invention, which is defined by the claims appended hereto.

[0169] Coating compositions based on organic solvents

[0170] In general, it has to be mentioned that all experiments (comprising experiments according to the invention as well as comparative examples outside the invention) have been carried out using organic solvent based coating compositions comprising microparticles Zinc, particulate aluminum, at least one additive, at least one binder comprising at least one titanate compound and at least one silane agent, and at least one organic solvent. The particulate zinc and particulate aluminum are provided in flakes having a diameter ranging from at least 5 μm to 15 μm. This is generally the optimum diameter for the particulate metals used in the present invention.

[0171] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com