Nonlinear optical device comprising potassium sodium niobate single crystal

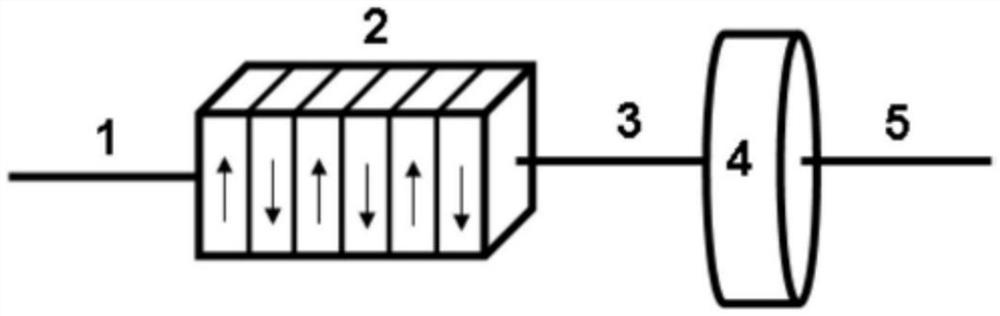

A nonlinear optics, potassium sodium niobate technology, applied in the field of optoelectronic functional materials, can solve problems such as difficulty in obtaining high optical quality large-size single crystals, difficulty in completely covering the atmospheric window, and inability to control growth parameters in real time, achieving large laser damage. Threshold, wide optical transmission wavelength range, no cracking issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: K 0.8 Na 0.2 NbO 3 Single crystal preparation

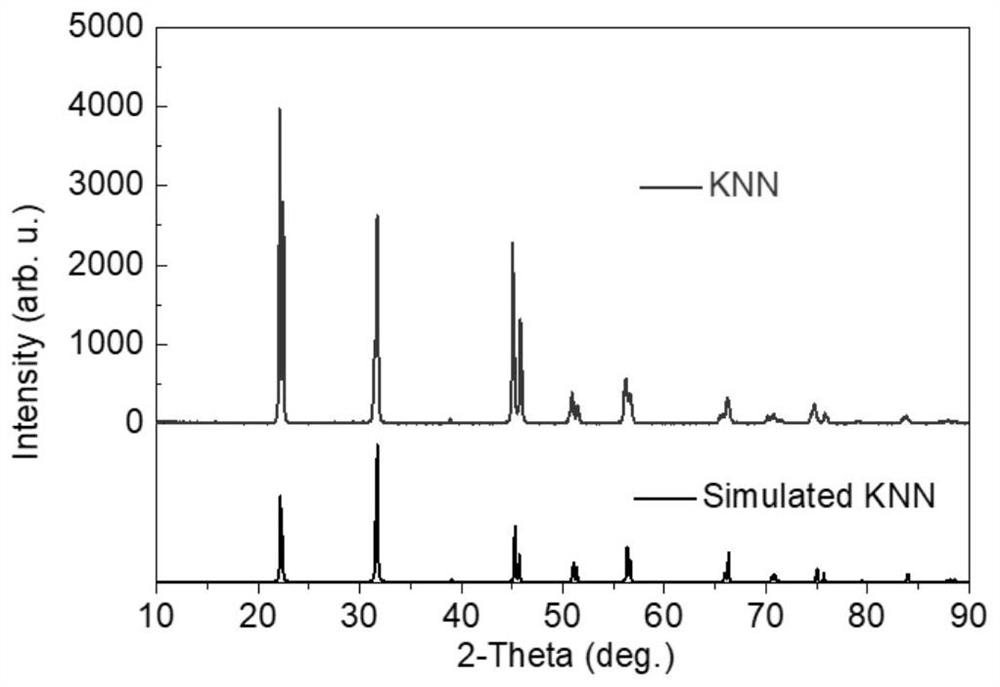

[0051] Na with a purity of 99.99% 2 CO 3 、K 2 CO 3 and Nb 2 o 5 The raw materials are weighed according to the stoichiometric ratio x=0.8, y=0, z=0, and then placed in vacuum drying at 120°C, and the polycrystalline potassium sodium niobate is synthesized by solid-phase sintering method, the solid-phase sintering temperature is 950°C, and the sintering The time is 20 hours; X-ray powder diffraction test is carried out to the prepared polycrystalline phase, test result is as follows image 3 As shown, it can be seen from the figure that the experimental value is consistent with the theoretical value, indicating that the obtained powder sample is a pure phase.

[0052] Put the obtained polycrystalline material into a platinum crucible, put it into a pulling furnace, and vacuumize the furnace cavity to 1×10 -4 Pa, fill with Ar to an atmospheric pressure, raise the temperature to melt the raw materials slo...

Embodiment 2

[0055] Example 2: Li 0.05 K 0.475 Na 0.475 NbO 3 Single crystal preparation

[0056] Na with a purity of 99.99% 2 CO 3 、K 2 CO 3 and Nb 2 o 5 Raw material according to stoichiometric ratio Li 0.05 K 0.475 Na 0.475 NbO 3 After weighing, it was placed in vacuum drying at 120° C., and the potassium sodium niobate polycrystalline material was synthesized by a solid-state sintering method.

[0057] Add the obtained polycrystalline material to the platinum crucible, and vacuumize until the obtained polycrystalline material is added to the platinum crucible, and vacuumize to 1×10 -4 Pa, filled with Ar+1%O 2 To an atmospheric pressure, raise the temperature to slowly melt the raw materials, and keep the temperature constant for 2 hours after all the raw materials are melted. After adjusting the seeding temperature, the potassium sodium niobate seed crystal is slowly lowered to the surface of the melt for shoulder and equal-diameter growth. The crystals are stripped as ...

Embodiment 3

[0058] Example 3: Li 0.05 K 0.475 Na 0.475 Sb 0.02 Nb 0.98 o 3 Single crystal preparation

[0059] Na with a purity of 99.99% 2 CO 3 、K 2 CO 3 and Nb 2 o 5 Raw material according to metering ratio Li 0.05 K 0.475 Na 0.475 Sb 0.02 Nb 0.98 o 3 After weighing, it was placed in vacuum drying at 120° C., and the potassium sodium niobate polycrystalline material was synthesized by a solid-state sintering method.

[0060] Add the obtained polycrystalline material to the platinum crucible, and vacuumize until the obtained polycrystalline material is added to the platinum crucible, and vacuumize to 1×10 -4 Pa, filled with Ar to an atmospheric pressure, raised the temperature to slowly melt the raw materials, and kept the temperature for 2 hours after all the raw materials were melted. After adjusting the seeding temperature, the potassium sodium niobate seed crystal is slowly lowered to the surface of the melt for shoulder and equal-diameter growth. The crystals are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com