Method and system for preparing low-carbon olefin from waste plastics

A technology for low-carbon olefins and waste plastics, applied in the field of solid waste plastics treatment, can solve the problems of easy deactivation of catalysts, easy corrosion of pipelines and equipment, and high impurity content, so as to solve the problems of white pollution, high solvent recycling rate and environmental protection. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

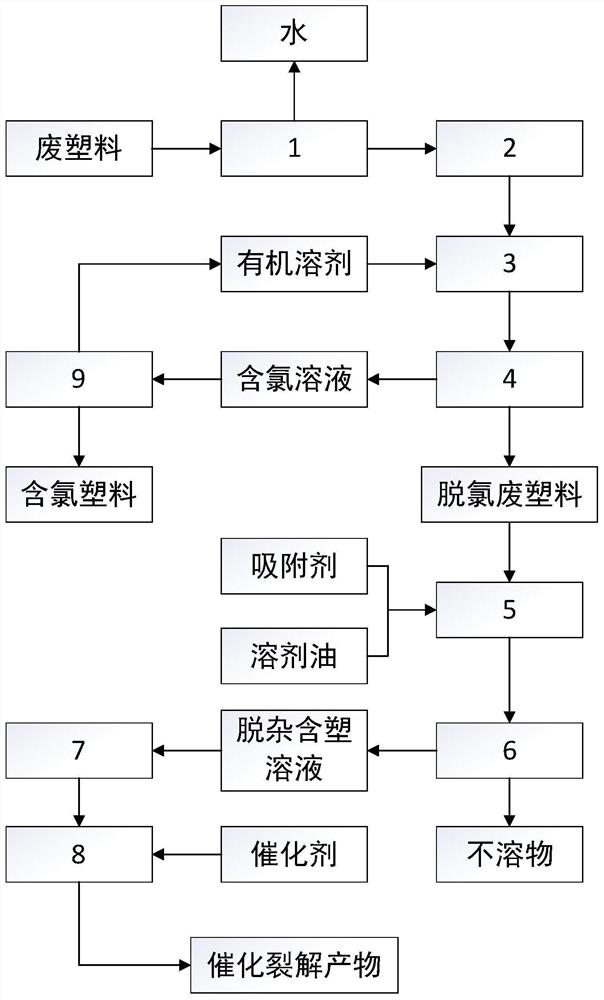

Method used

Image

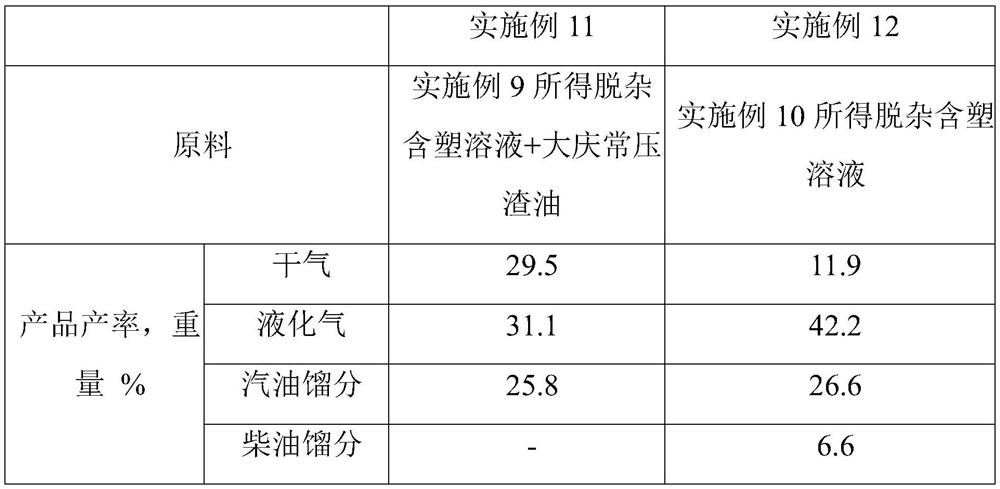

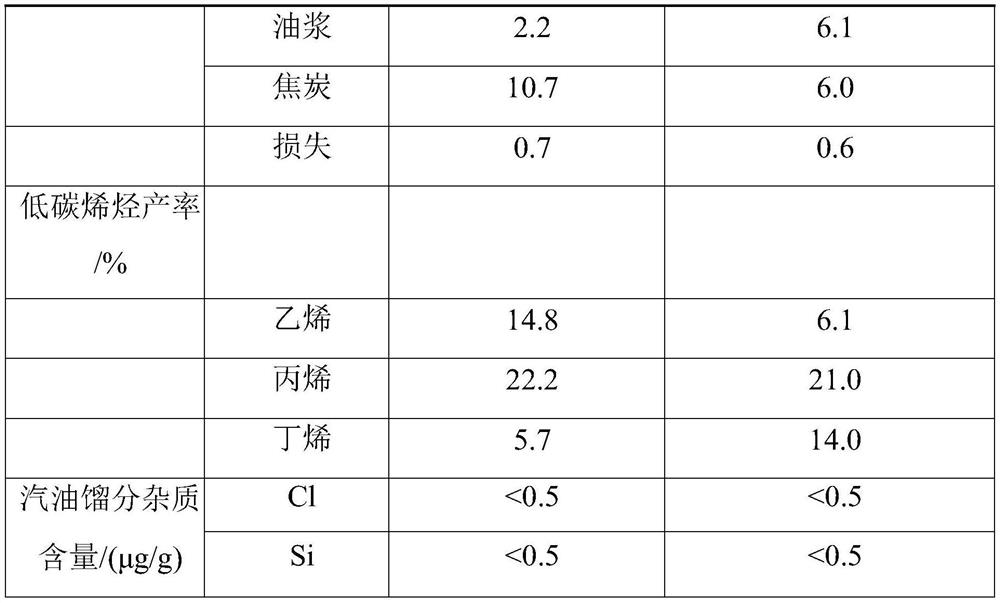

Examples

Embodiment 1~5

[0068] Waste plastic A is the waste plastic excavated from a waste landfill in Guangdong. After cleaning and drying, it is broken into <50mm. Heat up to 60°C and enter the waste plastic dissolving and dechlorination unit. The waste plastic dissolving and dechlorination unit adopts an external heating dissolving kettle. , The residence time of waste plastic A in the external heat dissolving tank is 30min, and the dissolved material is separated into chlorine-containing solution and dechlorinated waste plastic at 60°C through a screw extrusion desolventizer.

Embodiment 1

[0069] The organic solvent used in Example 1 is tetrahydrofuran, and the weight ratio of the organic solvent to the waste plastic A is 10:1; the chlorine content in the obtained dechlorinated waste plastic is 23 μg / g.

Embodiment 2

[0070] The organic solvent used in Example 2 was methyl ethyl ketone, and the weight ratio of the organic solvent to the waste plastic A was 10:1; the chlorine content in the obtained dechlorinated waste plastic was 20 μg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com