Waterborne epoxy emulsifier and preparation method thereof as well as waterborne epoxy resin dispersion and preparation method thereof

A water-based epoxy resin, water-based epoxy technology, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the complex production process of water-based epoxy emulsifiers, the lack of pot life and resistance of water-based epoxy resin dispersions , poor performance and other problems, to achieve the effect of low cost, low production cost and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

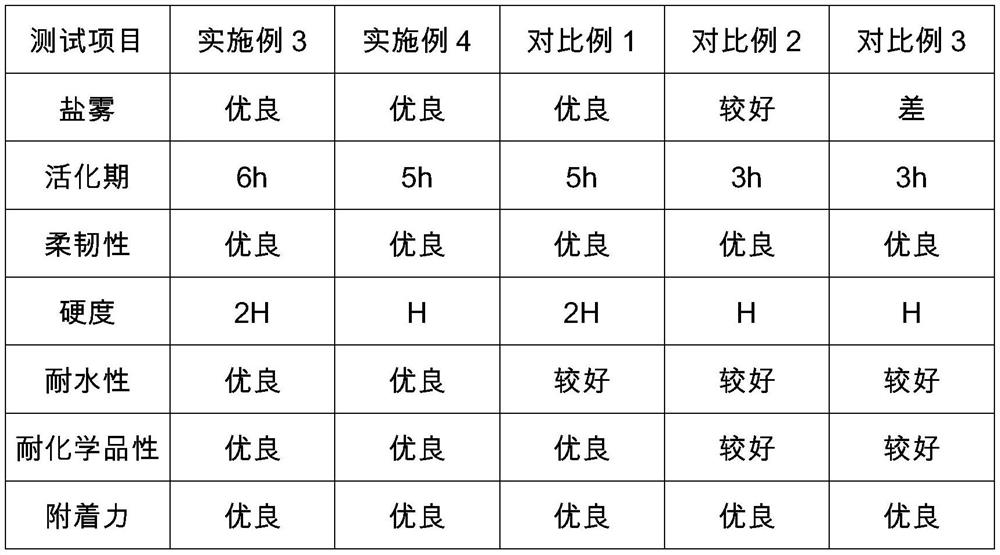

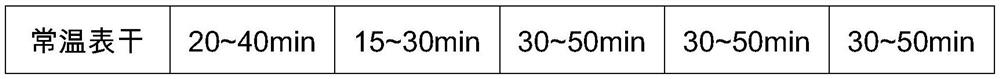

Examples

preparation example Construction

[0033] A method for preparing a water-based epoxy emulsifier, which is used to prepare the above-mentioned water-based epoxy emulsifier, comprising the following steps: adding polyether polyol to a reaction device, heating to 60°C-80°C, feeding nitrogen, stirring, and then Raise the temperature to 110°C-120°C, and perform vacuum pumping; when the temperature rises to 110°C-120°C, and the vacuum degree reaches -100kPa, start timing, after 1-3 hours of vacuuming, turn off the vacuuming, add acid anhydride, when the acid anhydride After uniform dispersion, the temperature is raised to 150°C to 180°C, and the reaction is continued for 2-4 hours to obtain a water-based epoxy emulsifier.

[0034] A water-based epoxy resin dispersion, calculated in parts by weight, comprising the following components: 60-150 parts of bisphenol A, 200-300 parts of bisphenol A glycidyl ether, 0.01-0.05 parts of ethyl triphenylphosphine acetate , 40-160 parts of solvent, 250-400 parts of deionized water...

Embodiment 1

[0044] A water-based epoxy emulsifier is obtained by reacting polyether polyol and acid anhydride, the molar mass ratio of polyether polyol and acid anhydride is 1:(1.3-2.5).

[0045] Specifically, the polyether polyol includes PEG-8000 and PEG-4000; the anhydride is adipic acid.

[0046] The preparation method of above-mentioned water-based epoxy emulsifier comprises the following steps, and the following components are calculated in parts by weight:

[0047] Step A100. Add 400g of PEG-8000 and 400g of PEG-4000 to the reaction device, heat to 60°C, blow in nitrogen, and stir;

[0048] Step A200. Raise the temperature to 120°C and vacuumize; when the temperature rises to 120°C and the relative vacuum reaches -100kPa, start timing and keep for 2 hours;

[0049] Step A300. End the vacuum state, add 46g of adipic acid, heat up to 170°C after the adipic acid is uniformly dispersed, and continue to react for 2 hours to obtain a water-based epoxy emulsifier.

[0050] A water-based...

Embodiment 2

[0056] A water-based epoxy emulsifier is obtained by reacting polyether polyol and acid anhydride, the molar mass ratio of polyether polyol and acid anhydride is 1:(1.3-2.5).

[0057] Specifically, the polyether polyol includes PEG-8000 and PEG-4000; the acid anhydride is methyl hexahydrophthalic anhydride.

[0058] Step A100. Add 300g of PEG-8000 and 450g of PEG-4000 into the reaction device, heat to 60°C, blow in nitrogen, and stir;

[0059] Step A200. Raise the temperature to 120°C and vacuumize; when the temperature rises to 120°C and the relative vacuum reaches -100kPa, start timing and keep for 2 hours;

[0060] Step A300. End the vacuum state, add 55g of methyl hexahydrophthalic anhydride, heat up to 170° C. after the methyl hexahydrophthalic anhydride is uniformly dispersed, and continue to react for 2 hours to obtain a water-based epoxy emulsifier.

[0061] A water-based epoxy resin dispersion, calculated in parts by weight, comprising the following components: 124 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com