Emulsion for hydraulic support

A hydraulic support and emulsion technology, applied in the field of emulsified oil, can solve the problems of hydraulic oil being difficult to degrade, pollute the environment, wear and so on, and achieve the effects of excellent extreme pressure lubrication, improved rust resistance and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The preparation method of the emulsion for hydraulic support in this embodiment is to add 67kg of water and 450kg of water-soluble castor oil into the reaction kettle, then add 80kg of boric acid and 5kg of sodium hydroxide, heat up to 90°C, and keep stirring for 30 minutes , then add 80kg of triethanolamine, keep stirring for 3 hours, add 8kg of Span-80 after the liquid is transparent, stir for 30 minutes, add 250kg of barium dinonylnaphthalenesulfonate and 15kg of zinc naphthenate , 20kg of dodecenyl succinic acid, 20kg of borax and 5kg of zinc dialkyl dithiophosphate, and continue to stir for 30 minutes to obtain the emulsion for the hydraulic support. Water-soluble castor oil is put into the reactor by 1 mass part of castor oil, 9 mass parts of ethylene glycol and 0.3 mass part of toluenesulfonic acid, heated up to 85°C, stirred for 3 hours, and rectified after condensation reaction. have to.

Embodiment 2

[0015] The preparation method of the emulsion for hydraulic support in this embodiment is to add 76kg of water and 420kg of water-soluble castor oil into the reaction kettle, then add 75kg of boric acid and 4kg of sodium hydroxide, heat up to 90°C, and keep stirring for 30 minutes , then add 75kg of triethanolamine, keep stirring for 3 hours, add 10kg of OP-10 after the liquid is transparent, stir for 30 minutes, add 280kg of barium dinonyl naphthalene sulfonate, 12kg of zinc naphthenate , 15kg of dodecenyl succinic acid, 25kg of borax and 8kg of zinc dialkyldithiophosphate, and continued to stir for 30 minutes to obtain the emulsion for the hydraulic support. Water-soluble castor oil is put into the reactor by 1 mass part of castor oil, 9.5 mass parts of ethylene glycol and 0.4 mass part of toluenesulfonic acid, heated up to 85°C, stirred for 3 hours, and rectified after condensation reaction. have to.

Embodiment 3

[0017] The preparation method of the emulsion for hydraulic support in this embodiment is to add 46kg of water and 480kg of water-soluble castor oil into the reaction kettle, then add 90kg of boric acid and 7kg of sodium hydroxide, heat up to 90°C, and keep stirring for 30 minutes , then add 90kg of triethanolamine, keep stirring for 3 hours, add 3kg of OP-10 and 3kg of Span-80 after the liquid is transparent, stir for 30 minutes, and add 220kg of barium dinonylnaphthalenesulfonate at 70°C, 18kg of zinc naphthenate, 25kg of dodecenylsuccinic acid, 15kg of borax and 3kg of zinc dialkyldithiophosphate, and continue stirring for 30 minutes to obtain an emulsion for hydraulic supports. Water-soluble castor oil is put into the reactor by 1 mass part of castor oil, 8.5 mass parts of ethylene glycol and 0.25 mass parts of toluenesulfonic acid, heated to 85 ° C, stirred for 3 hours, and rectified after condensation reaction. have to.

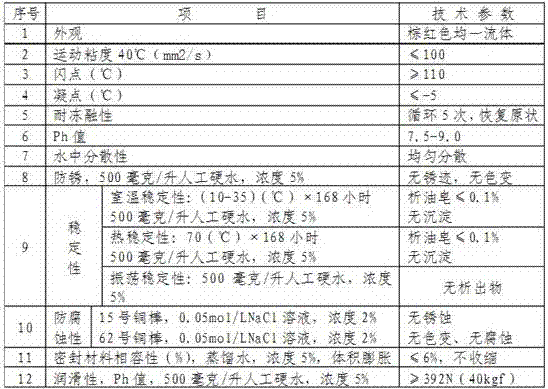

[0018] The emulsions for hydraulic supports in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com