Preparation method of pitaya juice

A technology of dragon fruit juice and dragon fruit, which is applied to the functions of food ingredients, food ingredients as antioxidants, food ingredients as color, etc., can solve the problems of dragon fruit peel discarding, waste of resources, etc. The effect of high sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

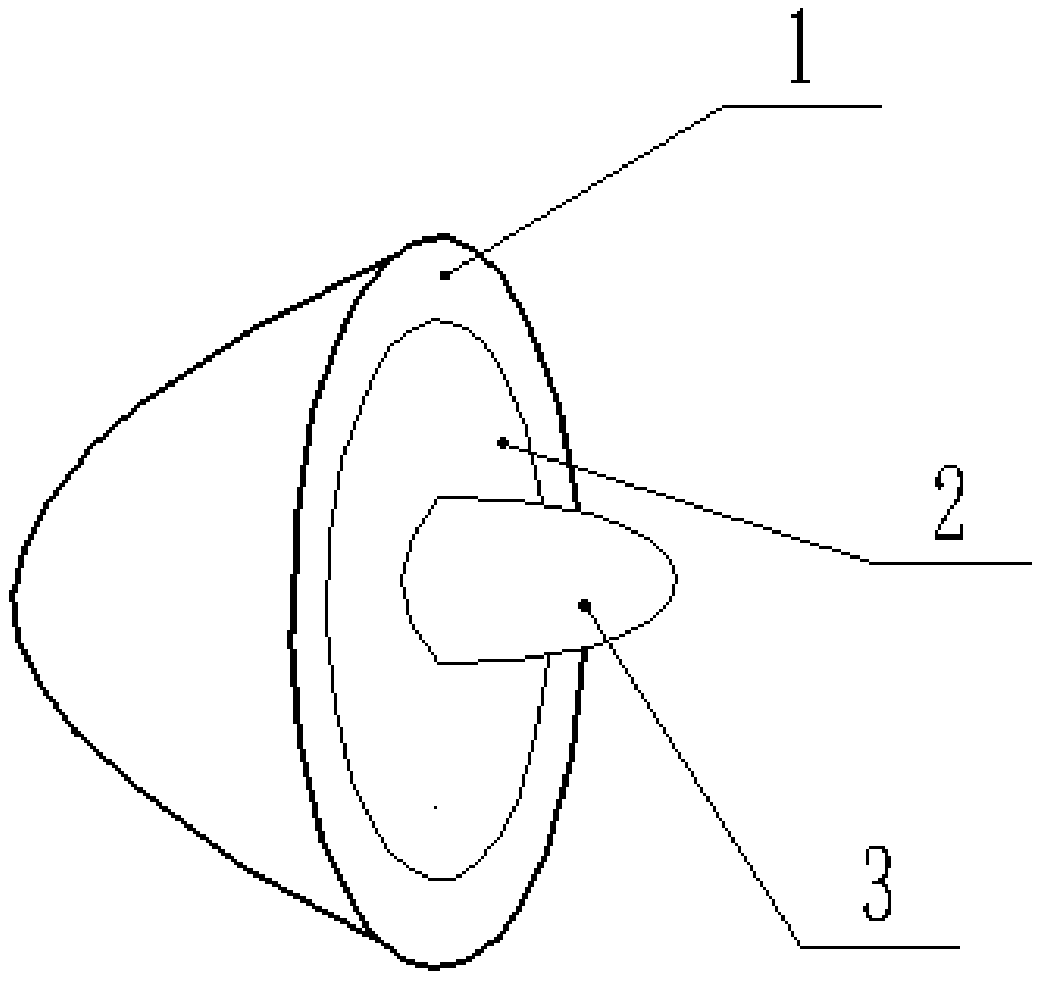

[0033] see figure 1 , the treatment agent of the present invention, including impurity removal layer 1, clarification layer 2 and stability maintenance layer 3.

[0034] The present embodiment provides a kind of preparation method of pitaya fruit juice, comprises the following steps:

[0035] (1) Dragon fruit pretreatment: take the dragon fruit and clean it and control the moisture, separate the peel from the pulp, cut the pulp into pieces, cut the peel into strips, and set aside;

[0036] (2) Pericarp treatment: scald the pericarp in 90°C water for 3 minutes, take out and drain the water and grind to obtain the pericarp pulp, add 5 times its volume and 70% ethanol in the gained pericarp pulp, soak at room temperature Extract for 1 hour, filter, and collect the filtrate and filter residue respectively; then extract pitaya red pigment from the obtained filtrate, and extract pectin from the obtained filter residue for subsequent use;

[0037] As mentioned above, the specific m...

Embodiment 2

[0044] The present embodiment provides a kind of preparation method of pitaya fruit juice, comprises the following steps:

[0045] (1) Dragon fruit pretreatment: take the dragon fruit and clean it and control the moisture, separate the peel from the pulp, cut the pulp into pieces, cut the peel into strips, and set aside;

[0046] (2) Pericarp treatment: scald the pericarp in water at 92° C. for 4 minutes, take out the drained water and grind to obtain the pericarp pulp, add 7 times its volume and 70% ethanol in the gained pericarp pulp, soak at room temperature Extract for 1.5h, filter, and collect the filtrate and filter residue respectively; then extract pitaya red pigment from the obtained filtrate, and extract pectin from the obtained filter residue for subsequent use;

[0047] As mentioned above, the specific method for extracting pitaya red pigment in the obtained filtrate is: after the filtrate is vacuum concentrated to dryness at 52°C, it is extracted and purified with...

Embodiment 3

[0054] The present embodiment provides a kind of preparation method of pitaya fruit juice, comprises the following steps:

[0055] (1) Dragon fruit pretreatment: take the dragon fruit and clean it and control the moisture, separate the peel from the pulp, cut the pulp into pieces, cut the peel into strips, and set aside;

[0056] (2) Pericarp treatment: scald the pericarp in 95°C water for 5 minutes, take out and drain the water and grind to obtain the pericarp slurry, add 10 times its volume and 70% ethanol in the obtained pericarp slurry, and soak at room temperature Extract for 2 hours, filter, and collect the filtrate and filter residue respectively; then extract pitaya red pigment from the obtained filtrate, and extract pectin from the obtained filter residue for subsequent use;

[0057] As mentioned above, the specific method for extracting pitaya red pigment in the obtained filtrate is: after the filtrate is vacuum concentrated to dryness at 55°C, it is extracted and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com