Preparation method and application of magnetic temperature-sensitive molecularly imprinted polymer based on eutectic solvent system

A low eutectic solvent and molecular imprinting technology, applied in chemical instruments and methods, analytical materials, material separation, etc., can solve problems such as few reports on identification characteristics and lack of research on stimuli responsiveness, so as to improve adsorption capacity and reuse. High sex, quick separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

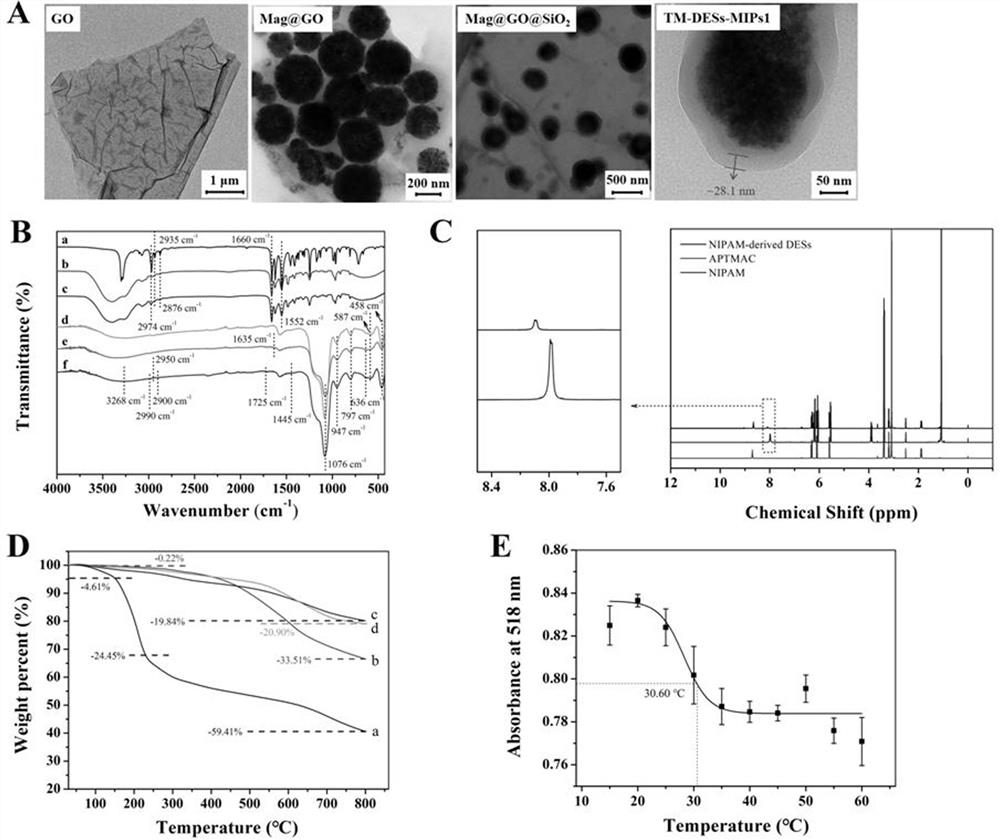

[0035] N-isopropylacrylamide (NIPAM) and (3-acrylamidopropyl)trimethylammonium chloride (APTMAC) were mixed at a molar ratio of 1:1 and heated at 80 °C for 1 h to form a homogeneous transparent liquid .

Embodiment 2

[0037] Weigh 1.0 g of graphite and 1.2 g of potassium nitrate, mix well, add 46 mL of chilled concentrated sulfuric acid (98%), and stir for 30 min in an ice-water bath. Slowly add 6.0 g of potassium permanganate to the above mixed solution, and continue stirring in an ice-water bath for 15 min. Remove the ice-water bath, raise the temperature of the reaction system to 35 °C, stir for 1 h, then slowly add 90 mL of ultrapure water, raise the temperature of the reaction system to 98 °C, and continue stirring for 30 min; then slowly pour 200 mL of The reaction temperature was controlled at 98 °C in hot ultrapure water. Next, add 6 mL of hydrogen peroxide (30%) dropwise until the color of the solution changes from dark brown to bright yellow; centrifuge while hot, and wash the centrifuged precipitate three times with 20 mL of hydrochloric acid (5%) and 200 mL of ultrapure water until the supernatant is neutral and free of SO 4 2- residue, graphene oxide (GO) was obtained after ...

Embodiment 3

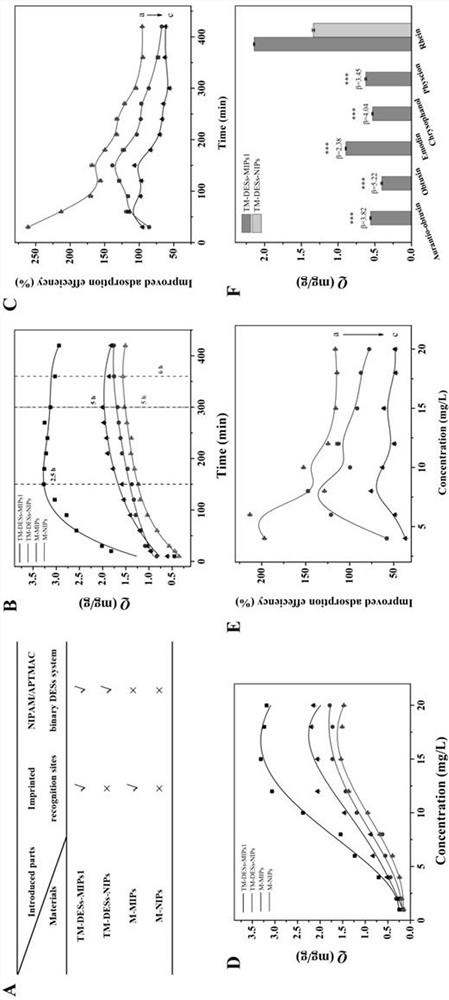

[0043] Based on the relationship between the peak area of HPLC and the concentration of the target analyte in the actual sample, three matrix-matched calibration curves were obtained. Rhein (RH), glycyrrhizinic acid (GA) and aristolochic acid I (AAI) were respectively in In the range of 0.05-8 mg / L, 0.5-25 mg / L and 0.04-8 mg / L, there was a good linear relationship, the correlation coefficient was between 0.9091 and 0.9904, and the detection limits for RH, GA and AAI were 16.67 and 363.64, respectively and 37.52 μg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com