Rotational flow demulsification dehydration separation device for water-containing oil liquid

A separation device, a technology for water-containing oil, which is applied in the direction of a swirling device, a device in which the axial direction of the swirling flow can be reversed, etc., can solve problems such as poor separation effect, and achieve improved separation efficiency, increased centrifugal force, and stable internal flow field. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

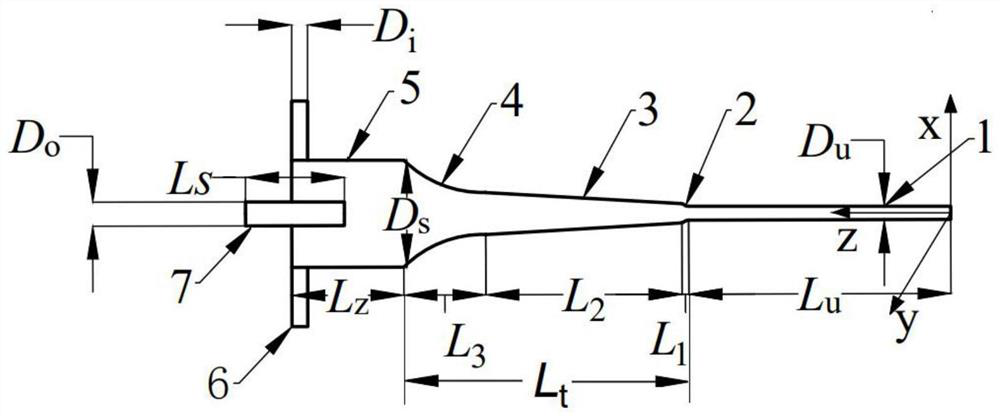

[0040] See Figure 3-Figure 5 , a cyclone demulsification dehydration separation device for water-containing oil, comprising a cyclone, the cyclone includes a cylindrical section of the cyclone chamber 5 and a bottom flow tube 1 coaxial with the cyclone chamber 5, the cyclone One end of the flow chamber 5 is open and the other end is closed. The closed end of the swirl chamber 5 is connected with an inlet pipe 6 and an overflow pipe 7 coaxial with the swirl chamber 5. The flow chamber 5 communicates, and the overflow pipe 7 insulates through the closed end of the swirl chamber 5 and communicates with the swirl chamber 5. The wall of the swirl chamber 5 and the overflow pipe 7 are all conductive materials; the open end of the swirl chamber 5 Facing the underflow pipe 1 and communicating with the underflow pipe 1 through a coaxial compound curve pipe section;

[0041]On the axial section of the swirl chamber 5, the inner wall of the compound curve pipe section includes a concav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com