A high-efficiency hydrocyclone with combined structure used in potash fertilizer production

A technology of hydrocyclone and combined structure, which is applied in the direction of swirl devices and devices whose axial direction of swirl can be reversed, etc., which can solve the problems of inability to deep process KCl products and affect product quality, and achieve compact structure, economy and reliability , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

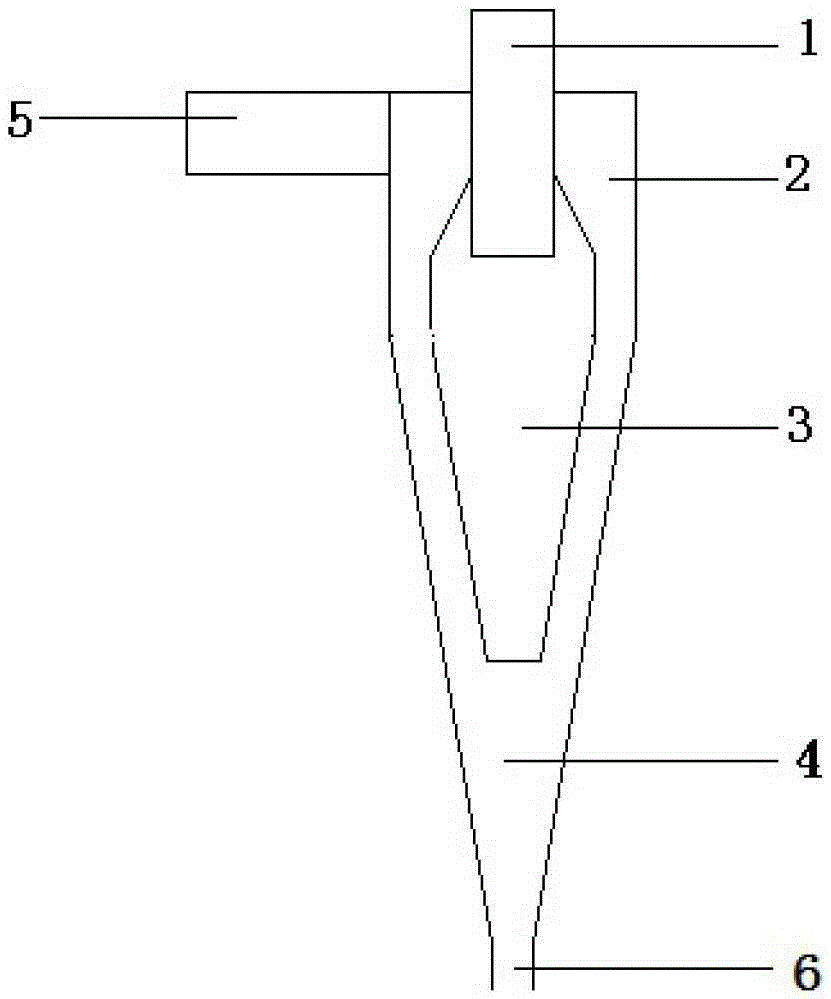

[0027] Please see attached figure 1 , a high-efficiency hydrocyclone with a combined structure used in potash fertilizer production, consisting of an overflow pipe 1, a cylindrical section 2, a combined structure 3 outside and lower end of the overflow pipe, a conical section 4, a feed pipe 5 and an underflow pipe 6 Composition; feed pipe and cylindrical section connected by welding. The cylindrical section 2 and the conical section are connected by threads, the inner surface of the lower sleeve of the cylindrical section is provided with an internal thread, and the outer surface of the upper sleeve of the conical section is provided with an external thread matching the internal thread of the cylindrical section. The conical section and the bottom flow pipe are connected by threads, and the compression sleeve fixes the bottom flow pipe through the threads on it.

[0028] The overflow pipe and the cylindrical section are connected through flanges, and the upper and lower flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com