Method for preparing coated crystals through microencapsulated crystallizing

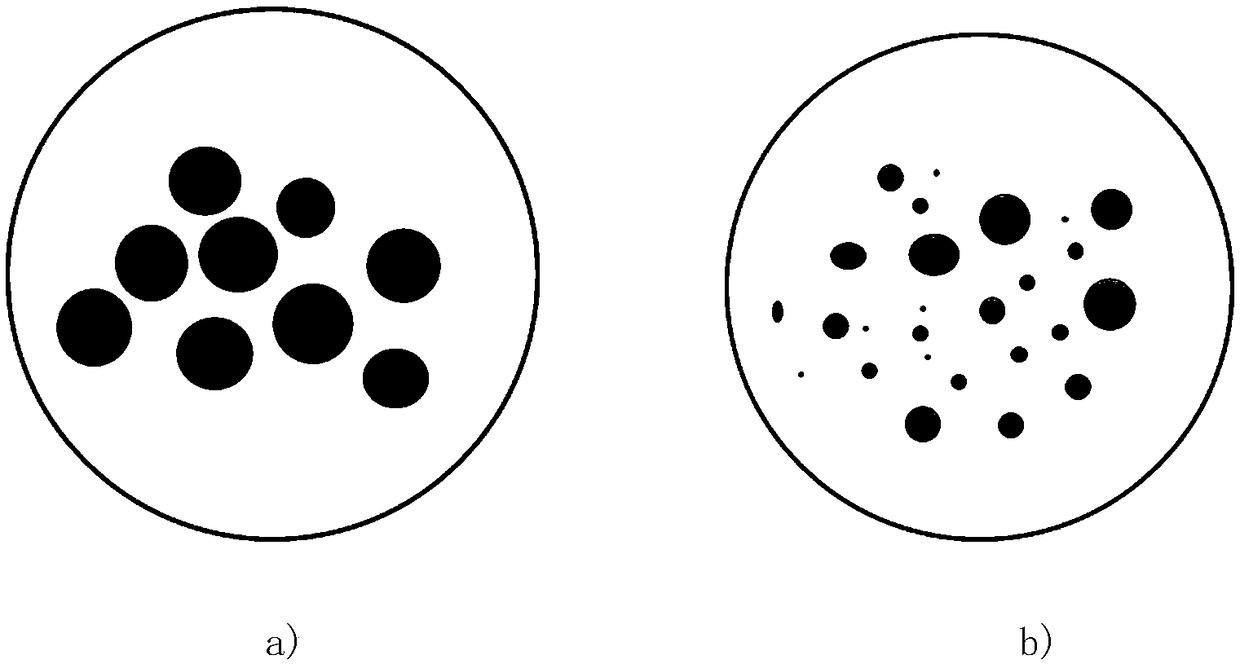

A technology of microcapsules and internal crystallization, applied in the field of microcapsule preparation and crystallization, can solve the problems of low crystal coating rate, poor crystal protection effect, crystal morphology and property control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0045] The continuous phase uses water as a solvent, prepares two equal volumes, respectively adds 2% polyethylene glycol 20000 as a protective colloid to the two solvents, stirs thoroughly to completely dissolve the polyethylene glycol 20000, and adds 3% Tween 80 was used as a surfactant, and 10% of 0.5 mol / L 1,6-hexanediamine was added to the other part as a reactive monomer.

[0046] The dispersed phase uses a mixed solution of chloroform and cyclohexane as a solvent, and the volume ratio of chloroform and cyclohexane is 2:1. The volume ratio of dispersed phase and continuous phase is 1:2. The vanillin to be crystallized is dissolved in the dispersed phase, and 10% of 0.5 mol / L terephthaloyl chloride is added as a reaction monomer.

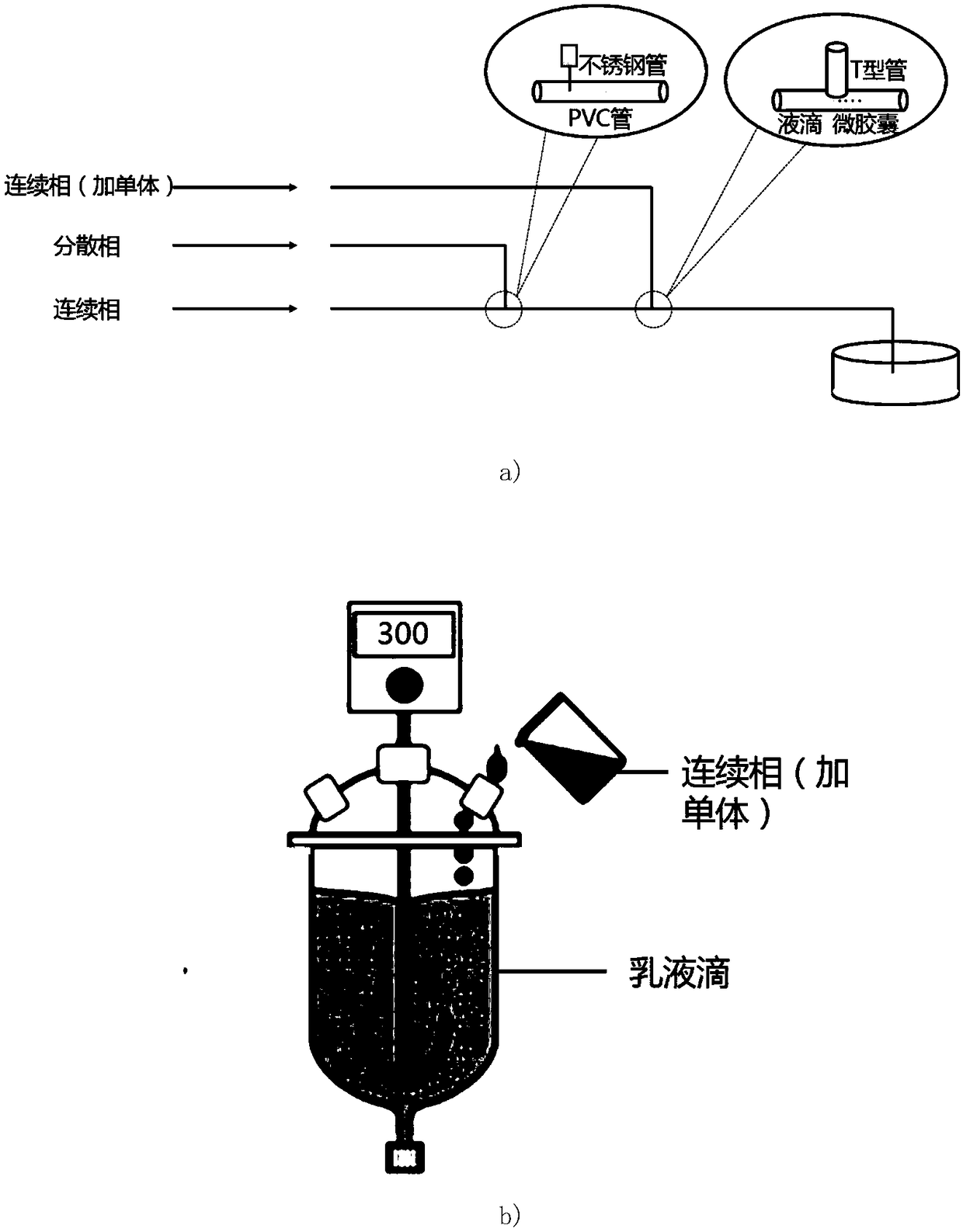

[0047] The microchannel used is composed of two focused flow microchannel modules coupled. The internal flow pattern of the first module is a cross type. A stainless steel pipe with an outer diameter of 0.31mm and an inner diameter of 0.16mm ...

Embodiment approach 2

[0052] For the continuous phase, a mixed solution of chloroform and cyclohexane with a volume ratio of 1:1 was used as a solvent, and two equal volumes were prepared, one was added with 2% Span 85 as a surfactant, and the other was dissolved with 20% of 1mol / L of terephthaloyl chloride as a reactive monomer. The dispersed phase uses water as a solvent, and 5% polyethylene glycol 20000 added to the water is used as a protective colloid, and 20% of 1mol / L 1,2-ethylenediamine and glycine to be crystallized are added, and the dispersed phase and the continuous phase The volume ratio is 1:3.

[0053] The microchannel used is composed of two focused flow microchannel modules coupled. The internal flow pattern of the first module is a cross type. A stainless steel pipe with an outer diameter of 0.31mm and an inner diameter of 0.16mm is inserted into the center of the PVC pipe. The outer diameter of the PVC pipe is 1.4mm and the inner diameter is 1.0mm. The internal flow type of th...

Embodiment approach 3

[0058] Prepare two equal volumes of continuous phase with water as solvent, add 5% polyethylene glycol 20000 as protective colloid to the two solvents respectively, stir well to dissolve polyethylene glycol 20000 completely, and add 2 % Tween 80 was used as a surfactant, and 10% of 1 mol / L 1,6-hexanediamine was added to the other part as a reactive monomer. The dispersed phase uses a mixed solution of chloroform and cyclohexane as a solvent, and the volume ratio of chloroform and cyclohexane is 2:1. The volume ratio of dispersed phase and continuous phase is 1:3. The vanillin to be crystallized is dissolved in the dispersed phase, and 10% of 1 mol / L terephthaloyl chloride is added as a reaction monomer.

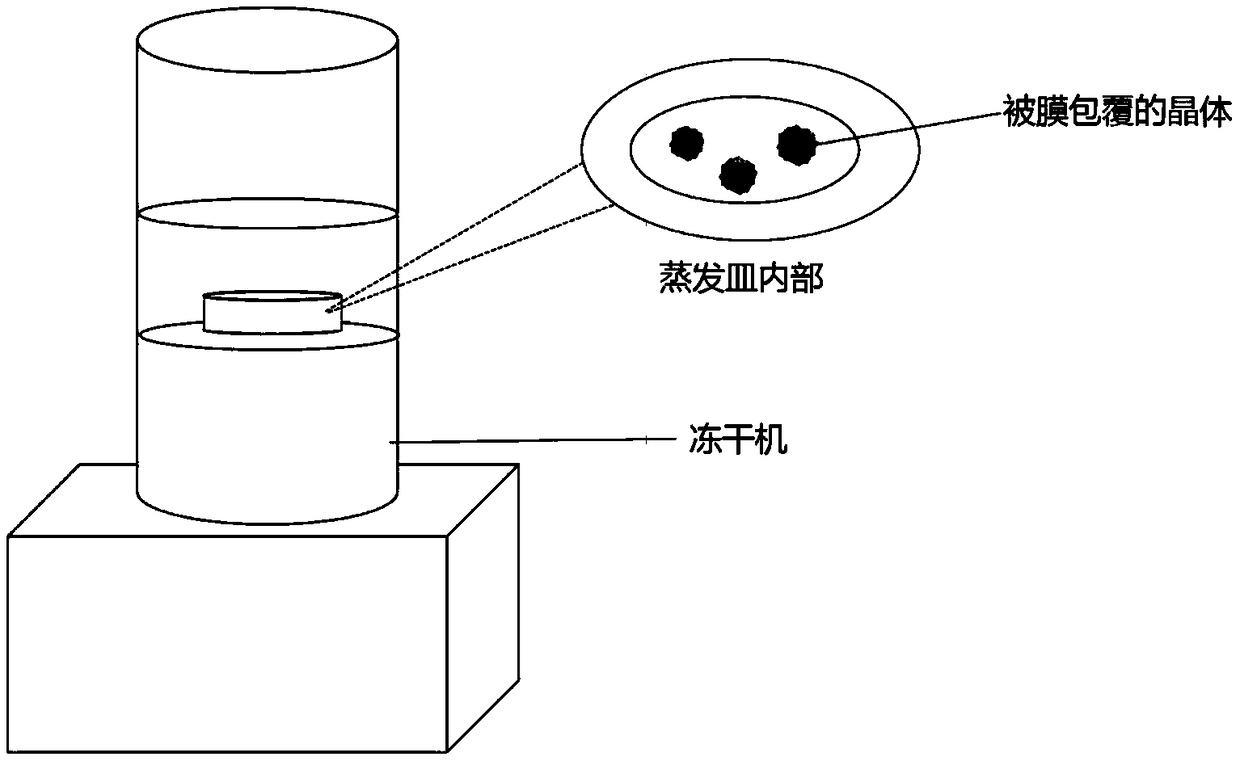

[0059] Add the continuous phase solution without adding monomer to the dispersed phase solution into the three-necked flask, and stir at a constant speed of 8000r / min to form an emulsion. After the emulsion is stable, add the continuous phase solution dissolved in 1,6-hexan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com