Metal phase layered molybdenum disulfide/reduced graphene oxide composite catalyst carrier and preparation method thereof

A graphene composite, catalyst carrier technology, applied in the field of nanomaterials, can solve the problems of poor anti-oxidation performance, poor conductivity of molybdenum disulfide catalyst carrier, low long-term stability, etc., and achieves improved mass transfer efficiency, low cost, and improved utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

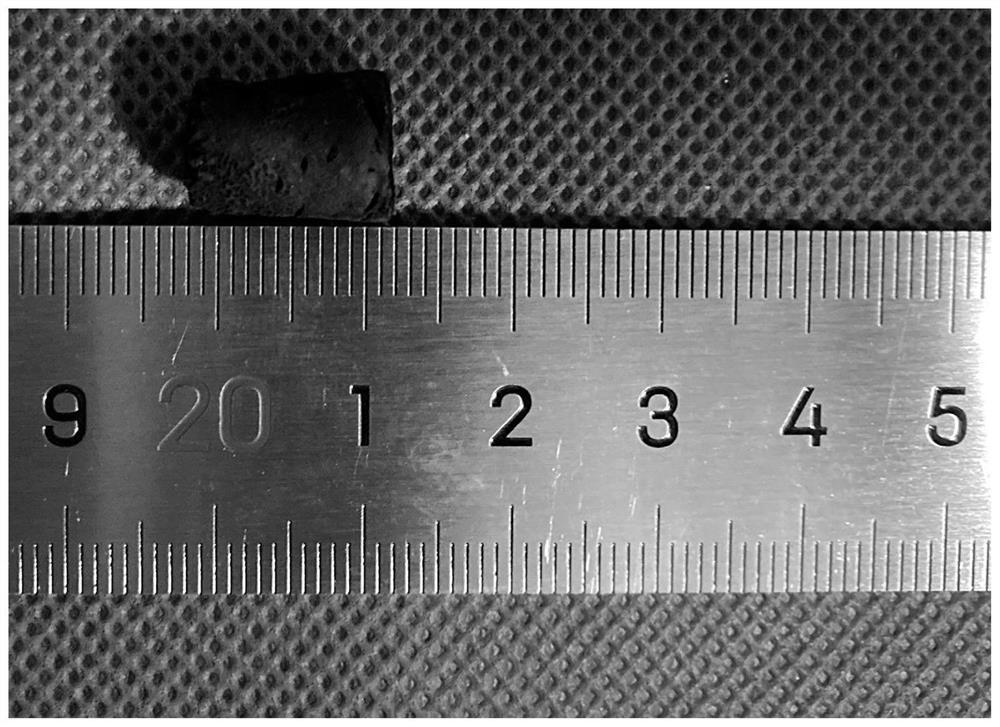

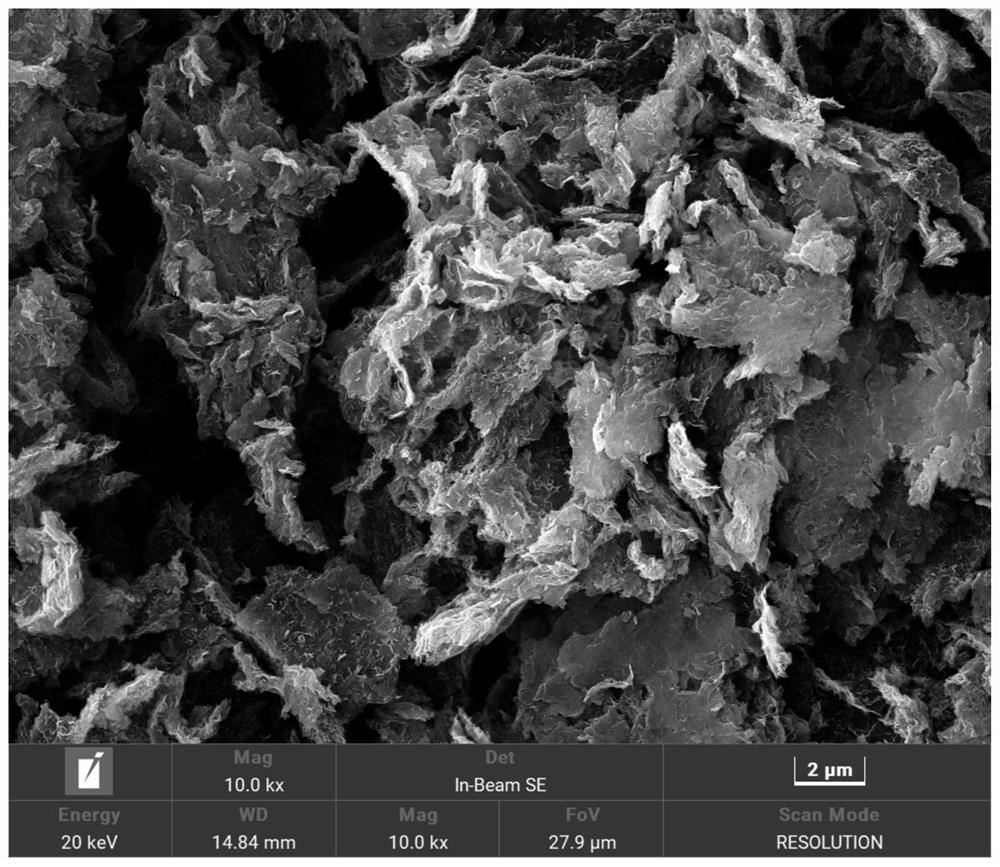

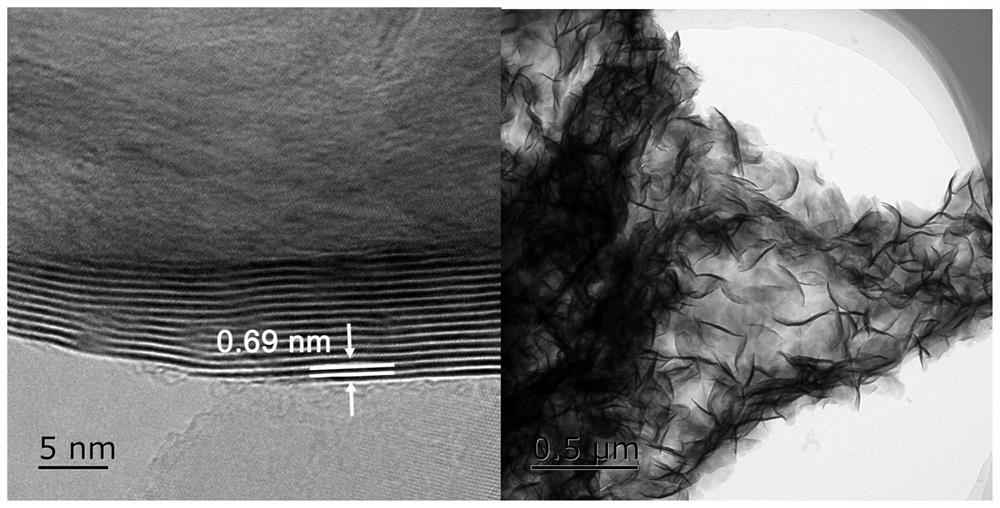

[0037] A preparation method of metal phase layered molybdenum disulfide / reduced graphene oxide composite catalyst carrier of the present invention comprises the following steps:

[0038] (1) Weigh 60 mg of graphene oxide flakes and disperse them in 30 mL of deionized water. After ultrasonic dispersion for 1 hour, add 300 μL of concentrated sulfuric acid (98 wt%) and 250 mg of citric acid in sequence, and continue ultrasonic dispersion for 1 hour to obtain a graphene oxide dispersion. The content of sulfur element in the graphene dispersion is 1.8mmol / mL.

[0039] (2) The graphene oxide dispersion was transferred to a 50 mL polytetrafluoroethylene reactor, and subjected to a hydrothermal reaction at a temperature of 180° C. for 12 hours to obtain a sulfur-doped reduced graphene oxide hydrogel.

[0040] (3) Wash the above-mentioned sulfur-doped reduced graphene oxide hydrogel with water, then use liquid nitrogen to freeze the sulfur-doped reduced graphene oxide hydrogel and dry ...

Embodiment 2

[0049] A preparation method of metal phase layered molybdenum disulfide / reduced graphene oxide composite catalyst carrier of the present invention comprises the following steps:

[0050] (1) Weigh 40 mg of graphene oxide flakes and disperse them in 30 mL of deionized water. After ultrasonic dispersion for 1 hour, add 150 μL of dimethyl sulfoxide and 250 mg of ascorbic acid in sequence, and continue ultrasonic dispersion for 1 hour to obtain a graphene oxide dispersion liquid, graphene oxide The elemental sulfur content in the dispersion was 0.07mmol / mL.

[0051] (2) The graphene oxide dispersion was transferred to a 50 mL polytetrafluoroethylene reactor, and reacted at a temperature of 180° C. for 24 hours to obtain a sulfur-doped reduced graphene oxide hydrogel.

[0052] (3) Wash the above-mentioned sulfur-doped reduced graphene oxide hydrogel with water, then carry out vacuum drying treatment, the temperature of vacuum drying treatment is 80 ° C, and then place it in a tube ...

Embodiment 3

[0055] A preparation method of metal phase layered molybdenum disulfide / reduced graphene oxide composite catalyst carrier of the present invention comprises the following steps:

[0056] (1) Weigh 80 mg of graphene oxide flakes and disperse them in 30 mL of deionized water. After ultrasonic dispersion for 1 hour, add 100 mg of sulfur powder and 200 mg of sodium citrate in turn, and continue ultrasonic dispersion for 1 hour to obtain a graphene oxide dispersion. The sulfur element content in the liquid is 0.05mmol / mL.

[0057] (2) The graphene oxide dispersion was transferred to a 50 mL polytetrafluoroethylene reactor, and reacted at a temperature of 200° C. for 18 hours to obtain a sulfur-doped reduced graphene oxide hydrogel.

[0058] (3) Wash the above-mentioned sulfur-doped reduced graphene oxide hydrogel with water, then use a rotary evaporator to dry it, and then place it in a tube furnace, and treat it at 700°C for 2h under the protection of argon gas at a flow rate of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com