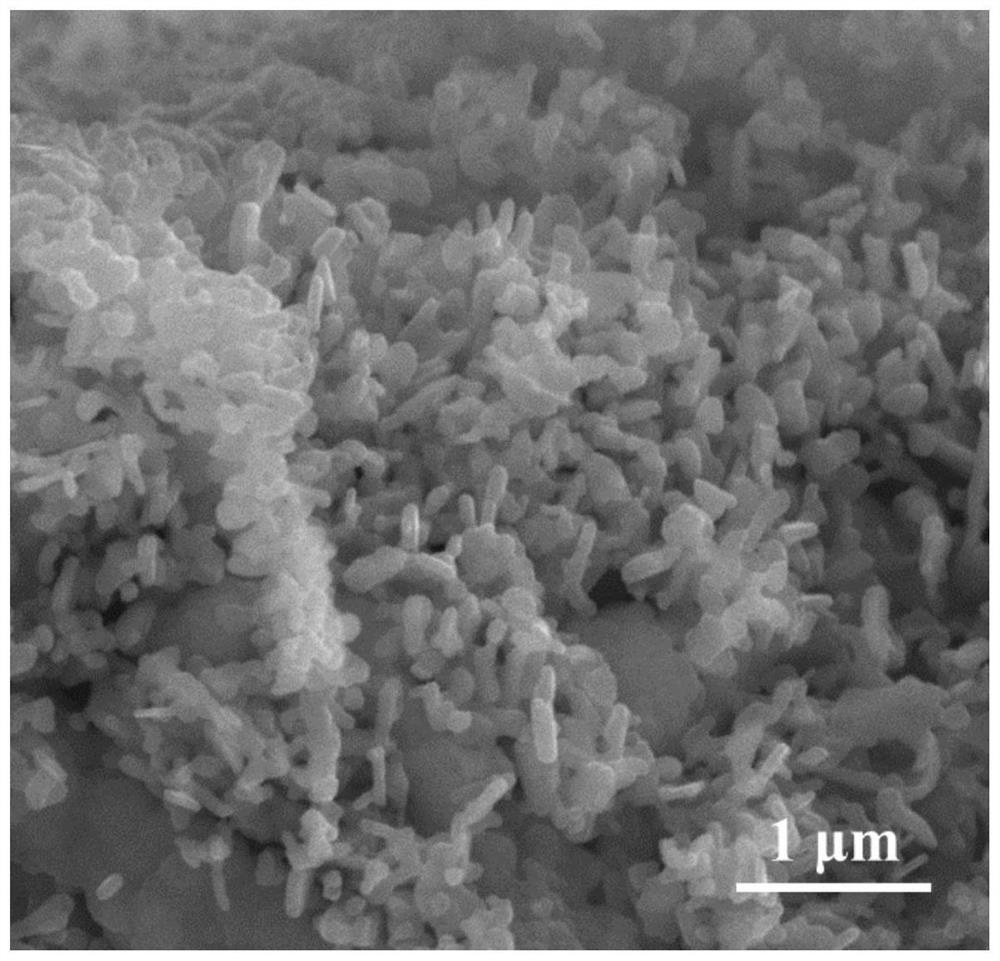

Preparation method of nickel-rich NCM811 nanoparticles

A technology of NCM811 and nanoparticles, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor particle size uniformity, achieve uniform particle size and easy control, good spinnability, crystal lattice well-developed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

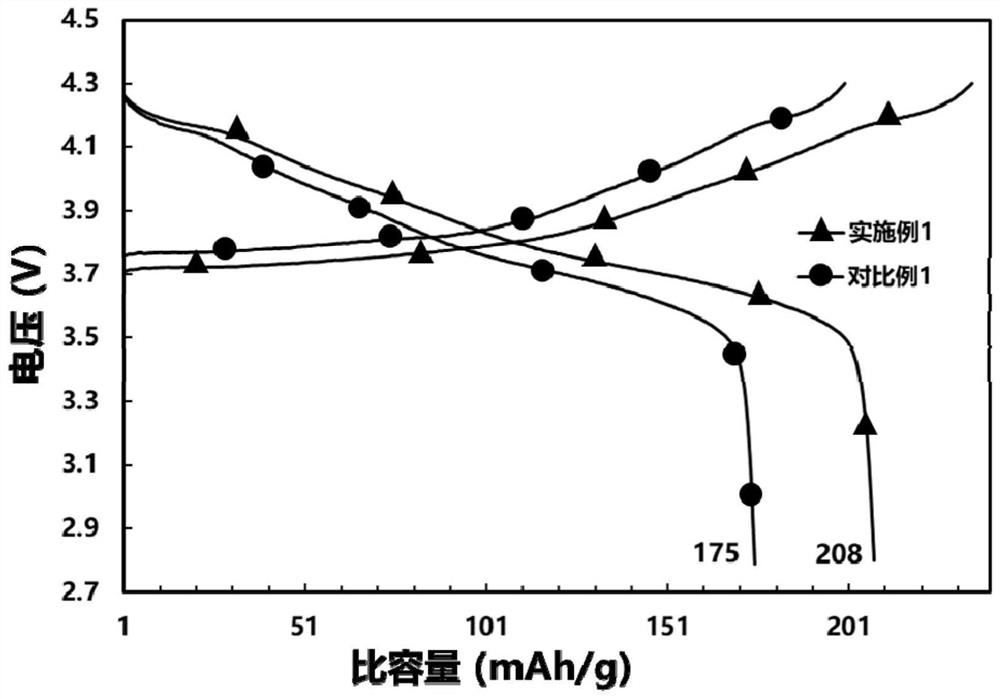

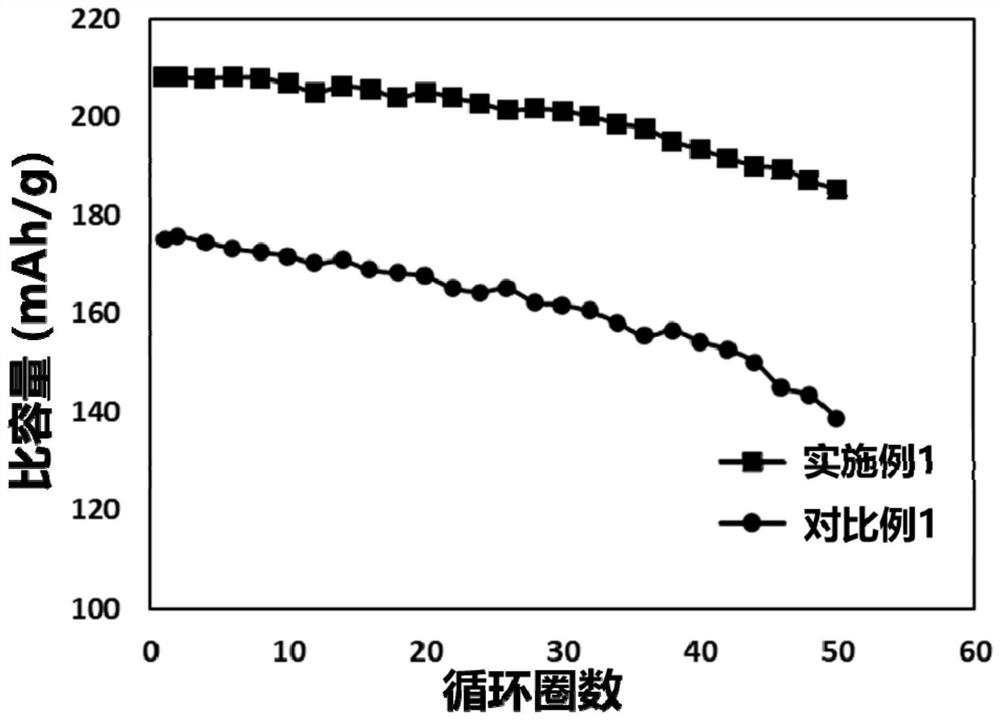

[0046] Preparation of battery samples: Mix nickel-rich NCM811 nanoparticles with Ketjen black conductive agent at a mass ratio of 9:1 and dissolve them in PVDF binder glue (mass concentration is 10%), nickel-rich NCM811 nanoparticles and Ketjen black conductive agent The mass volume ratio of the mixture of piano black conductive agent and PVDF binder glue is 10:1, and then coated on the positive electrode current collector by an automatic coating machine, and then subjected to vacuum high-temperature desolventization treatment to make nano-nickel-rich NCM811 Electrode pole piece; cut the pole piece into a disc with a diameter of 13mm with a cutting machine, and then assemble it into a button-type CR2025 half-cell in the glove box;

[0047] Constant current charge and discharge test:

[0048] Use the electrochemical workstation to set the charge and discharge current into 0.1C, 0.2C, 0.5C, 1C, 1.5C, 2C, 2.5C and 0.2C (where 1C=180mAh / g), charge and discharge, and then use the v...

Embodiment 1

[0053] A preparation method of nickel-rich NCM811 nanoparticles, the specific steps are as follows:

[0054] (1) PVP polymer and g-C 3 N 4 Be dispersed in the ethanol aqueous solution that volume concentration is 55%, stir to form uniform PVP solution; Wherein, the concentration of PVP polymer in the PVP solution is 5wt%, g-C 3 N 4 The concentration is 0.1wt%;

[0055] (2) Dissolve the lithium source, nickel source, cobalt source and manganese source with a molar ratio of 1.05:0.8:0.1:0.1 in the PVP solution to obtain an electrospinning precursor solution; wherein, 1.8L is compounded per 1 mol of manganese source PVP solution;

[0056] (3) Transfer the electrospinning precursor solution to a needle syringe, perform electrospinning, and obtain a nickel-rich NCM811 precursor nanofiber film on the receiving device. This embodiment has good spinnability;

[0057] The process parameters of electrospinning are: spinning voltage 10kV, curing distance 25cm, injection speed 0.8mL / ...

Embodiment 2

[0084] A preparation method of nickel-rich NCM811 nanoparticles, the specific steps are as follows:

[0085] (1) PVP polymer and g-C 3 N 4 Be dispersed in the aqueous ethanol solution that volume concentration is 58%, stir to form uniform PVP solution; Wherein, the concentration of PVP polymer in the PVP solution is 9wt%, g-C 3 N 4 The concentration is 0.15wt%;

[0086] (2) Dissolve the lithium source, nickel source, cobalt source and manganese source with a molar ratio of 1.06:0.8:0.1:0.1 in the PVP solution to obtain an electrospinning precursor solution; wherein, compound 1.9L per mol of manganese source PVP solution;

[0087] (3) Transfer the electrospinning precursor solution to a needle syringe, perform electrospinning, and obtain a nickel-rich NCM811 precursor nanofiber film on the receiving device. This embodiment has good spinnability;

[0088] The process parameters of electrospinning are: spinning voltage 13kV, curing distance 23cm, injection speed 1mL / h, relat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com