Preventive maintenance judgment method, device and equipment for main condenser and storage medium

A main condenser, preventive technology, applied in the direction of instrumentation, design optimization/simulation, computer-aided design, etc., can solve the problem that the main condenser cannot be judged for preventive maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It should be understood that the specific embodiments described here are only used to explain the present application, and are not intended to limit the present application.

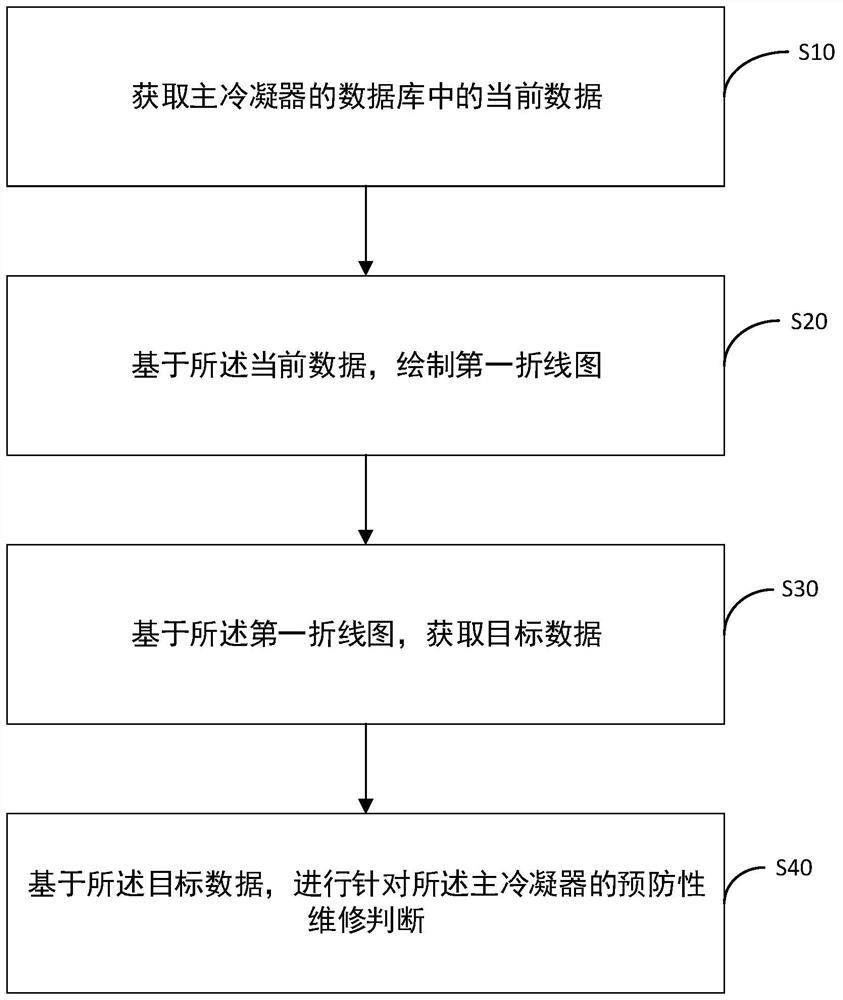

[0042] The main solution of the embodiment of this application is:

[0043] obtain the current data in the database of the main condenser;

[0044] Draw a line graph based on the current data;

[0045] Obtain target data based on the line chart;

[0046] Based on the target data, a preventive maintenance judgment for the main condenser is made.

[0047] The main condenser installed in the autoclave has an important influence on the temperature regulation ability during the curing process of the autoclave parts and the cooling ability at the end, but the main condenser is a fully enclosed structure in the form of a branch pipe array with cooling fins. It is extremely difficult to disassemble and repair the tail of the autoclave. Once an obvious failure occurs, it will be too late, affecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com