Support span adjusting device for rotating assembly and machine tool

A technology of adjusting devices and rotating components, which is applied in the field of machine tools, can solve the problems affecting the processing quality and production efficiency of machine tools, and the difficulty of adjusting the support span of rotating components, etc., to achieve the effect of prolonging the service life and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The invention will be further described below with reference to the accompanying drawings.

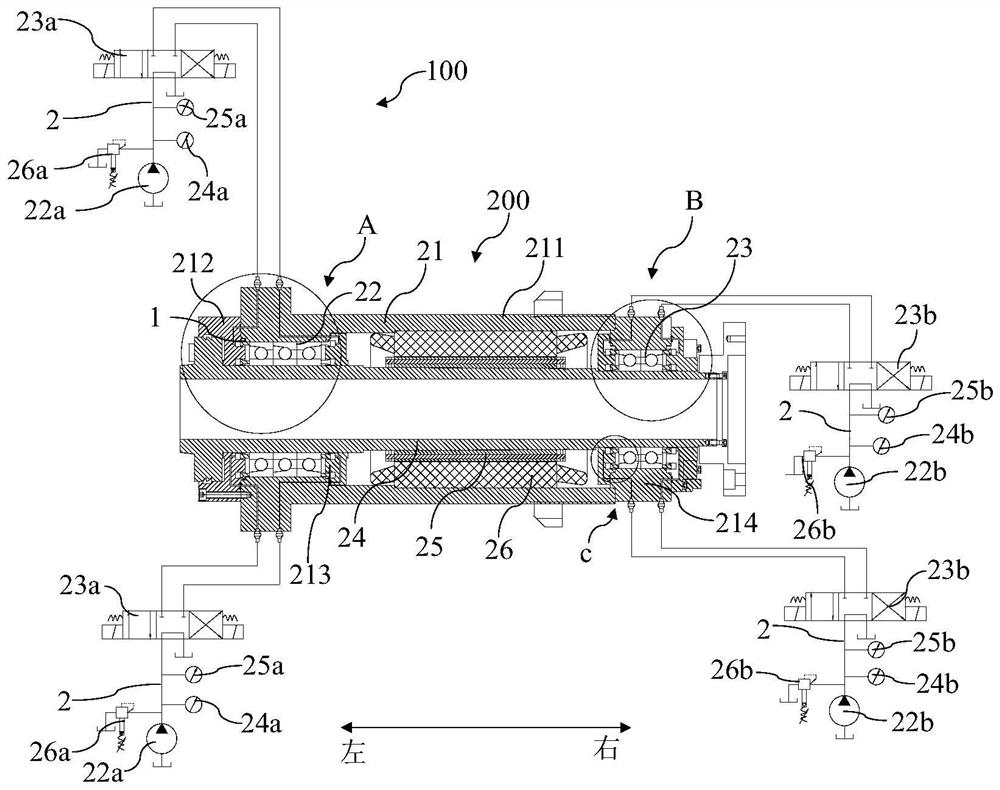

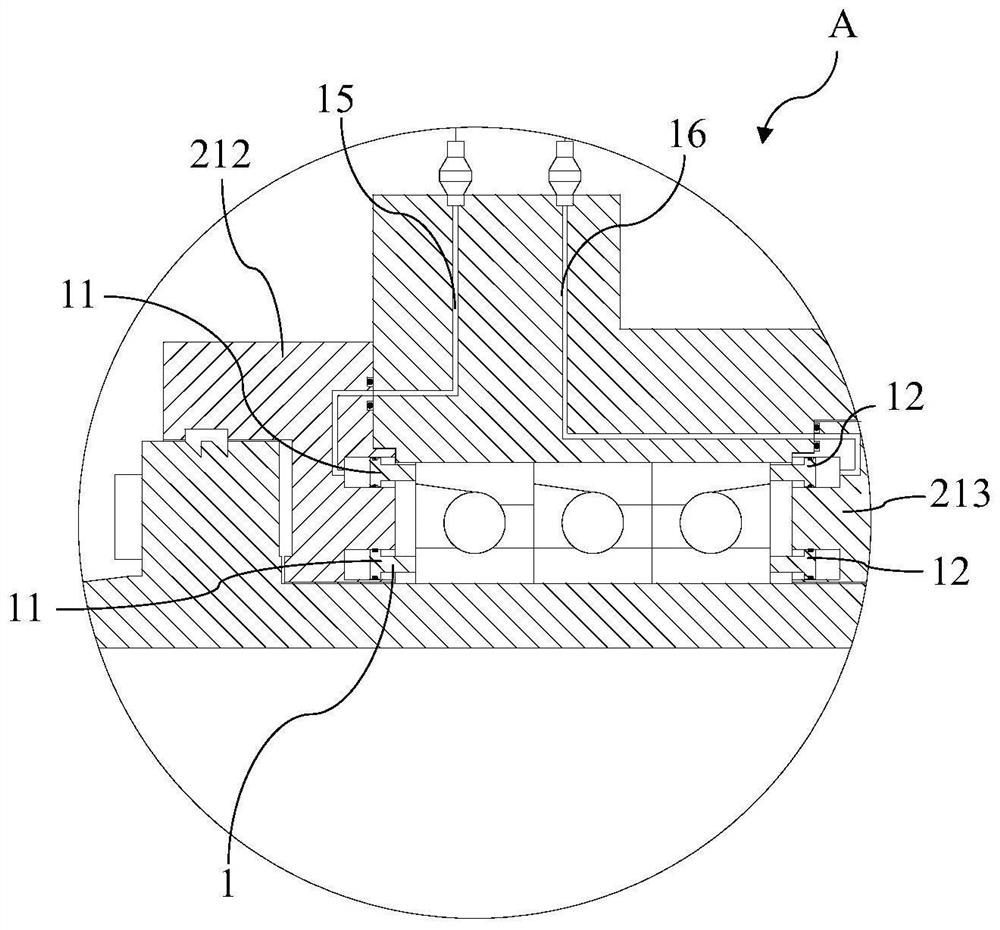

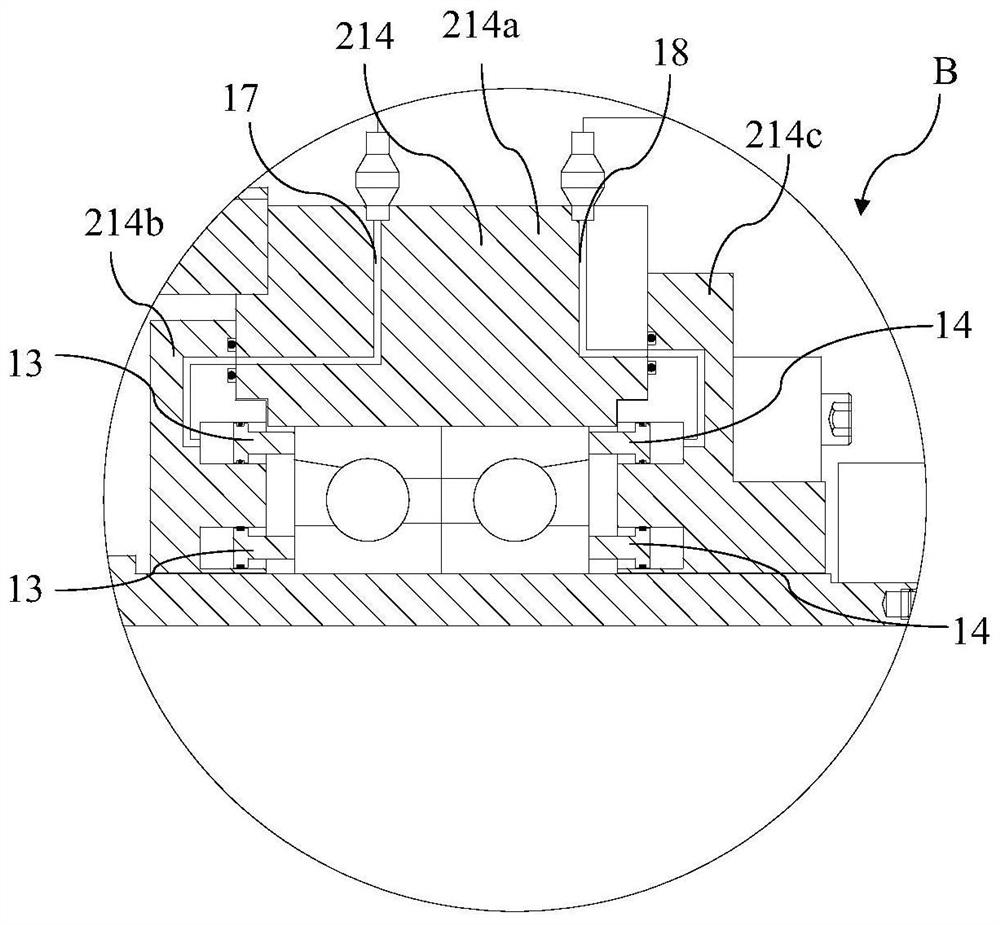

[0024]figure 1 The use state diagram of the support span adjustment device of the embodiment of the present invention is shown schematically.figure 2 forfigure 1 The large map is enlarged in Chinese a.image 3 forfigure 1 In the middle b. Such asfigure 1 ,figure 2 withimage 3 As shown, the support span adjustment device 100 of the embodiment of the present invention is applied to the rotating assembly 200. The rotating assembly 200 mainly includes a carrier assembly 21, which is provided in the carrier assembly 21 and the left bearing assembly 22 and the right bearing assembly 23 spaced apart from the left-right direction, and in the left-right direction, in the left-right direction, within the left-right direction. The shaft 24. The rotating assembly 200 is preferably a spindle assembly of the machine, and its shaft is the spindle of the machine.

[0025]In the present embodiment, the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com