Guide rail supporting device

A technology of a supporting device and a guide rail, which is applied in the field of guide rails, can solve the problems of lateral displacement of the I-shaped rail 100, inability to effectively lift the I-shaped rail 100, and laborious lifting of the I-shaped rail 100.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

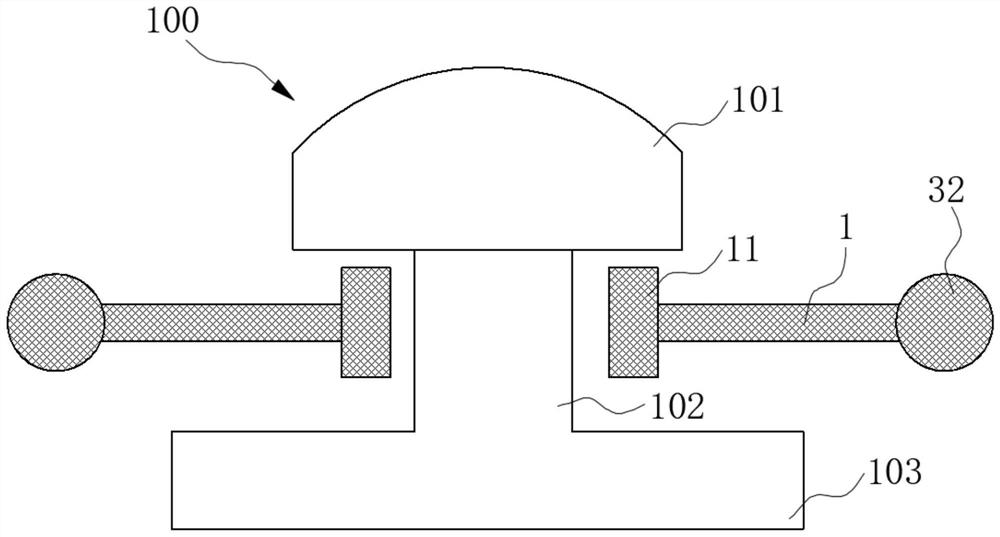

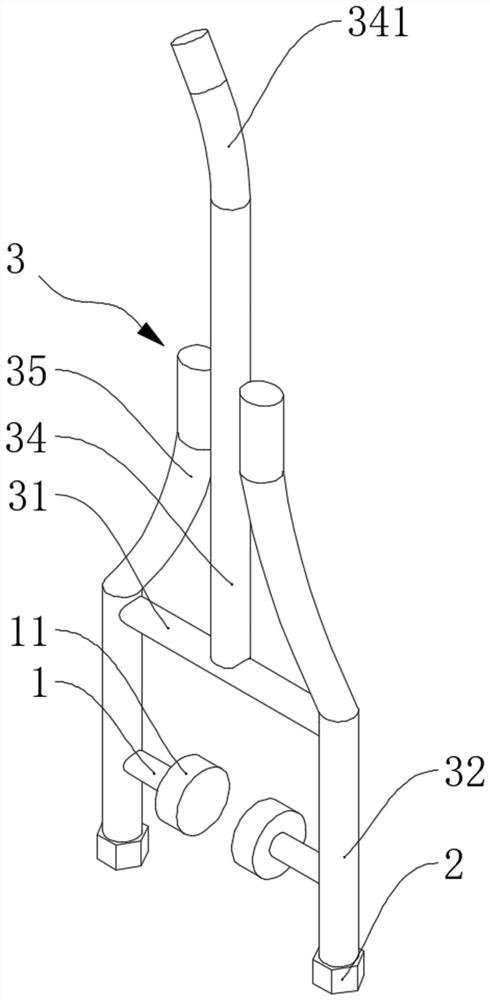

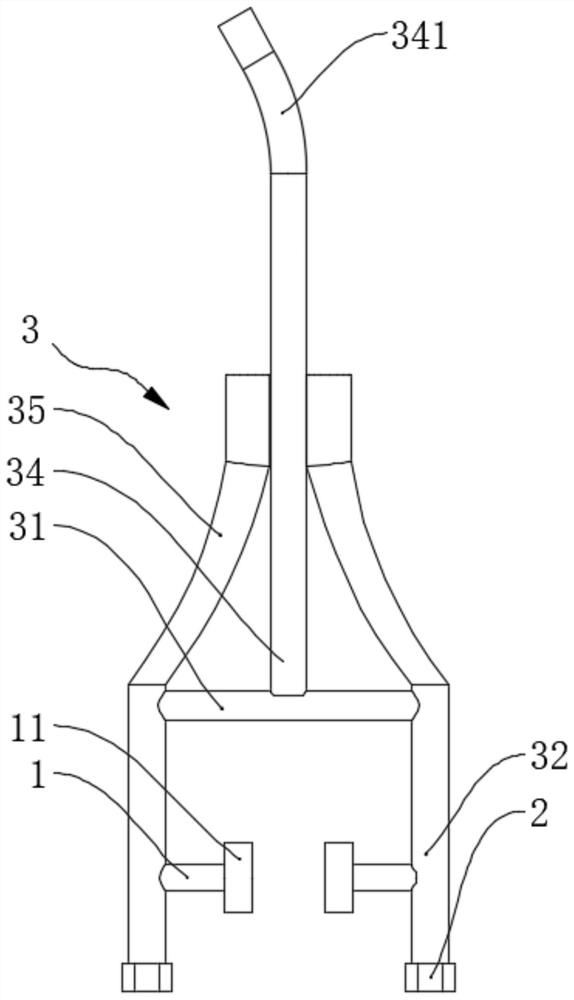

[0039] figure 1 A schematic structural view of the I-shaped rail 100 in the prior art is shown, and the specific structure of the I-shaped rail 100 has been described in detail in the background art. figure 2 A schematic structural view of the guide rail support device in this embodiment is shown, image 3 A schematic front view of the rail support device in this embodiment is shown. refer to Figure 1-Figure 3 , this embodiment provides a guide rail support device for supporting the I-shaped rail 100, which can be used in the field of guide rail technology, and can be erected on both sides of the I-shaped rail 100 to complete the lifting of the I-shaped rail 100.

[0040] Continue to refer to Figure 1-Figure 3 , the guide rail support device includes a support frame 3, a guide rail support 1 and a ground support 2, two guide rail supports 1 are provided, and the two guide rail supports 1 are fixedly connected with the support frame 3 respectively, and can be respectively...

Embodiment 2

[0051] Figure 4 A schematic structural view of the guide rail support device in this embodiment is shown, Figure 5 A schematic top view of the rail support device in this embodiment is shown. refer to Figure 4-Figure 5 , this embodiment provides a rail support device, on the basis of Embodiment 1, it also includes the following structure:

[0052] refer to figure 1 , Figure 4-Figure 5 , the rail support device also includes a drive assembly 4, the drive assembly 4 includes a driver 41, the driver 41 includes a driver body 411 and a telescopic rod 412 that can slide relative to the driver body 411, the driver body 411 can be supported on the ground, telescopic The rod 412 is rotatably connected with the support frame 3 and is used to drive the support frame 3 . When lifting is required, the ground support 2 and the driver body 411 are supported on the ground, and the driver 41 is used instead of manpower to drive the support frame 3. The telescopic rod 412 is elongated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com