Method for testing mercury content in lithium ion battery graphite negative electrode material

A lithium-ion battery, graphite anode technology, applied in battery electrodes, analytical materials, material analysis by optical means, etc., can solve problems such as measurement interference, achieve high accuracy, improve stability and accuracy, and fast analysis speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] 1. Preparation of standard solution

[0025] (1) 3% sodium borohydride solution: draw 3.000g of sodium borohydride into a 100ml glass volumetric flask and use deionized water to make up the volume. This is a reducing agent, which is used for the reaction between the hydride generator and the sample solution to generate mercury vapor.

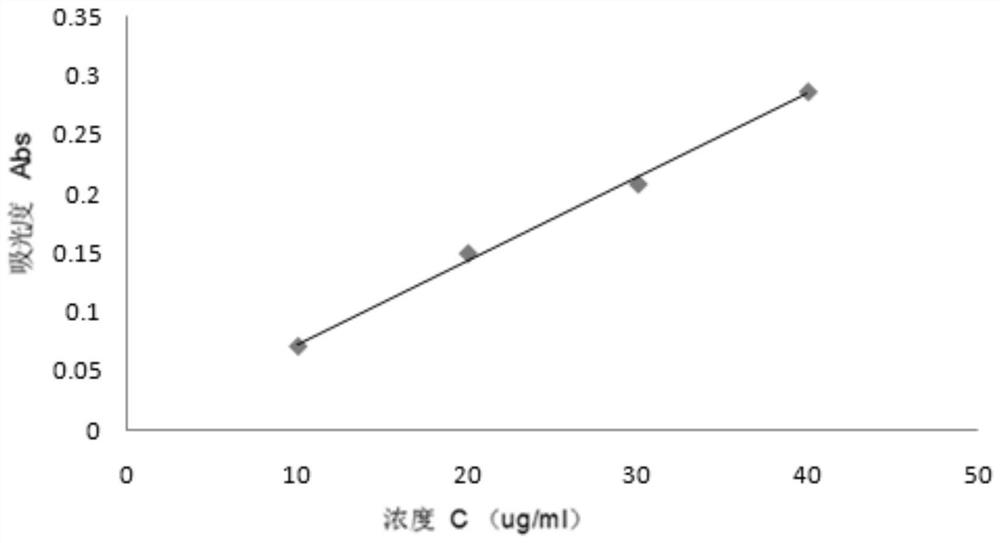

[0026] (2) Mercury standard solution: use deionized water to gradually dilute the mercury standard solution (1000ug / ml) into mercury standard solutions with concentrations of 10.0, 20.0, 30.0, 40.0ug / ml.

[0027] (3) Sample blank: add 20mL, 2wt% aqueous solution of ammonium pyrrolidine dithiocarbamate, oscillate and mix for reaction, then add 20mL methyl isobutyl ketone, oscillate and mix, let stand to separate layers, remove water Phase, collect the organic phase, transfer the organic phase to a 100mL glass volumetric flask, use methyl isobutyl ketone to make up to volume, add 2-3 drops of potassium permanganate solution before volume up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com