Oil tank cover and oil tank

A fuel tank cap and fuel tank technology, applied in the charging system, machine/engine, liquid fuel feeder, etc., can solve the problems of fuel volatilization, insufficient tightening, loose fuel tank cap, etc., to increase the tightness, improve stability, The effect of maintaining pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

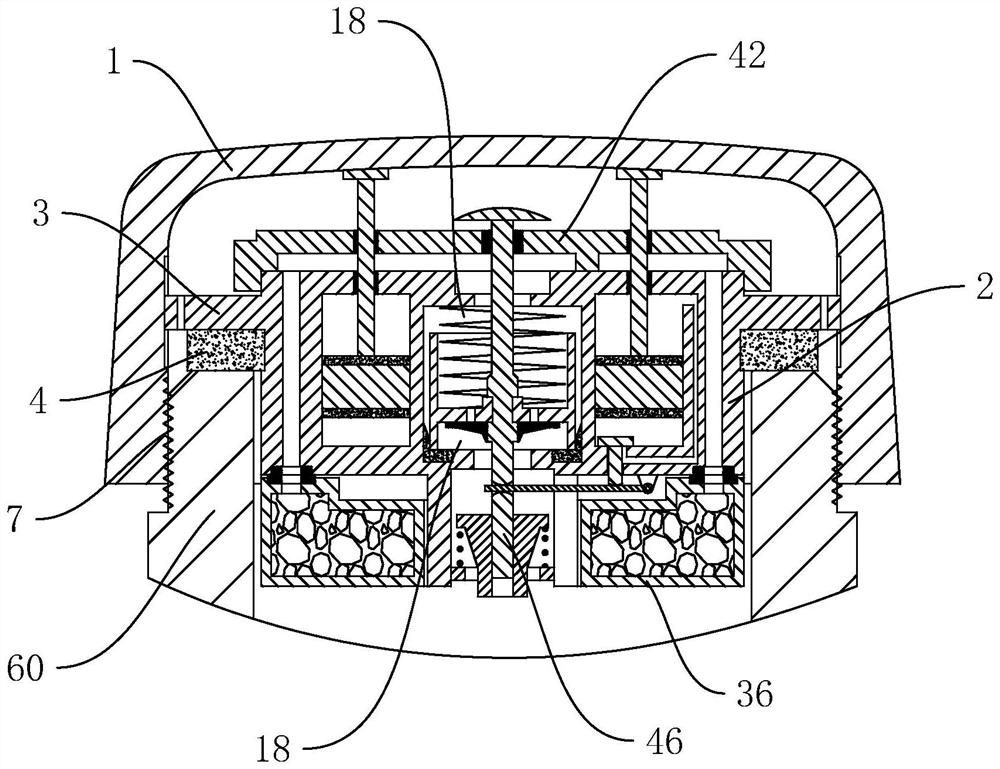

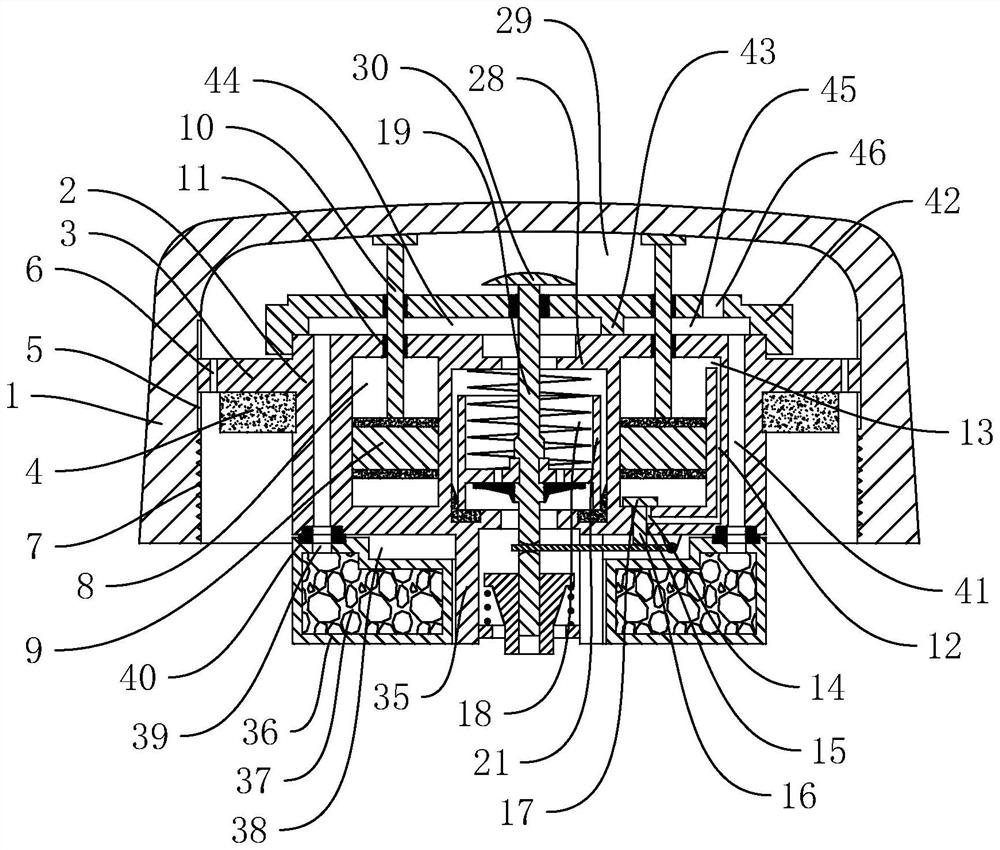

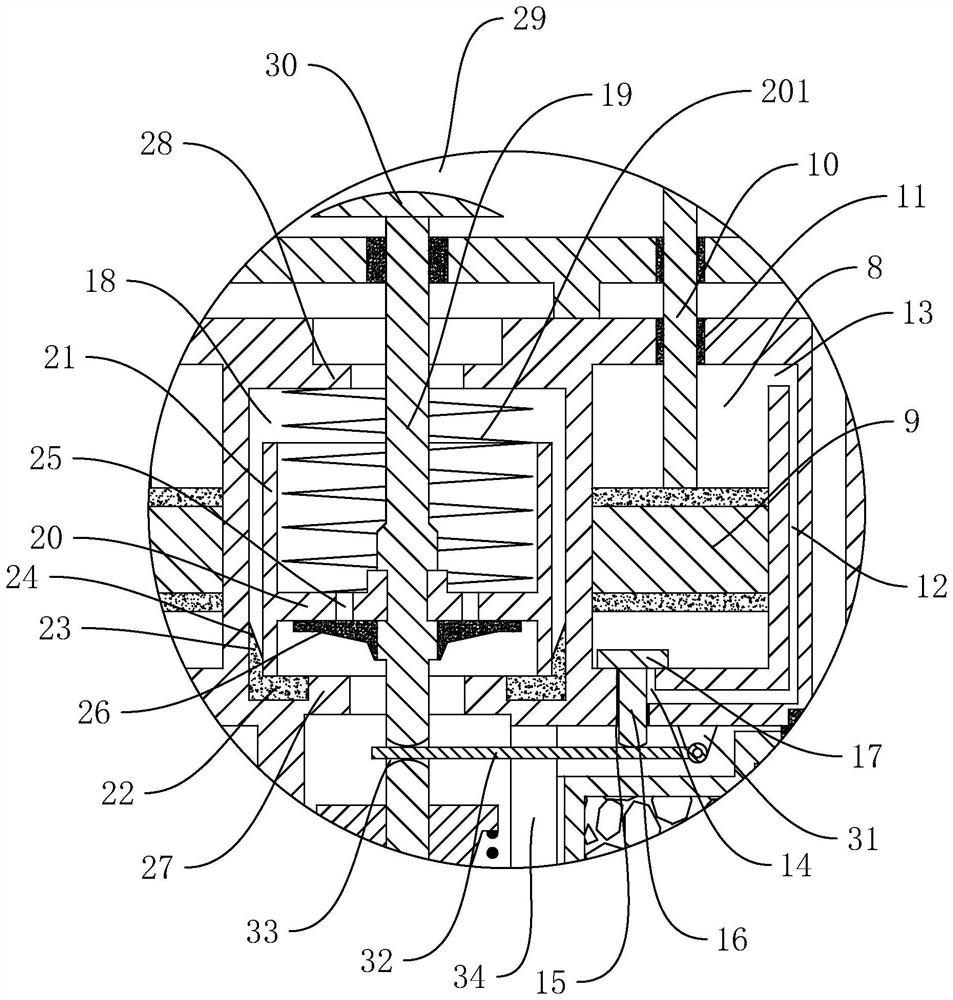

[0034] Embodiment: a kind of fuel tank cover, as Figure 1-7 As shown, it includes an outer cover 1 and an inner cover 2, wherein the inner circumference of the outer cover 1 has an internal thread 7, and the inner cover 2 is installed in the outer cover 1, and a chute 5 is also provided on the inner circumference of the outer cover 1, and the chute 5 Along the telescopic direction of the inner cover 2, the outer periphery of the retaining ring 3 is slidably connected in the chute 5, so that the inner cover 2 can be adjusted telescopically along the outer cover 1; during installation, it is compatible with the external thread 7 of the fuel tank port 60 to realize the installation , the inner cover 2 can partially extend into the middle of the fuel tank port 60 . The outer periphery of the inner cover 2 is fixed with a stop ring 3, and the end face of the stop ring 3 is sleeved with a sealing ring-4, and the sealing ring-4 can seal the connection position of the two when the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com