Clinker silo steel roof structure using welding balls and bolt balls in mixed mode

A technology of clinker silo and bolt ball, which is used in large-capacity bulk material storage, roof, building components, etc. Easy to construct and improve the effect of clear height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

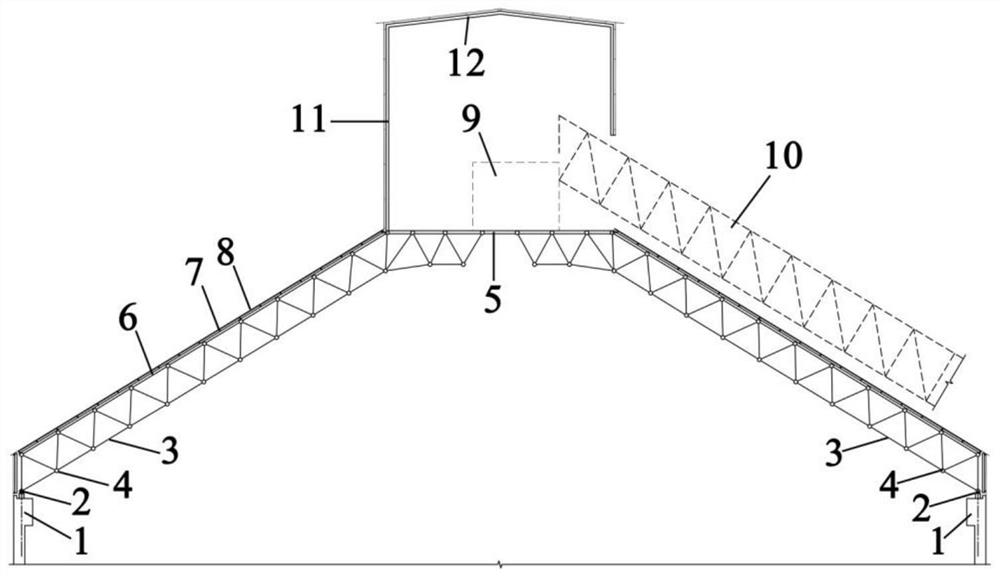

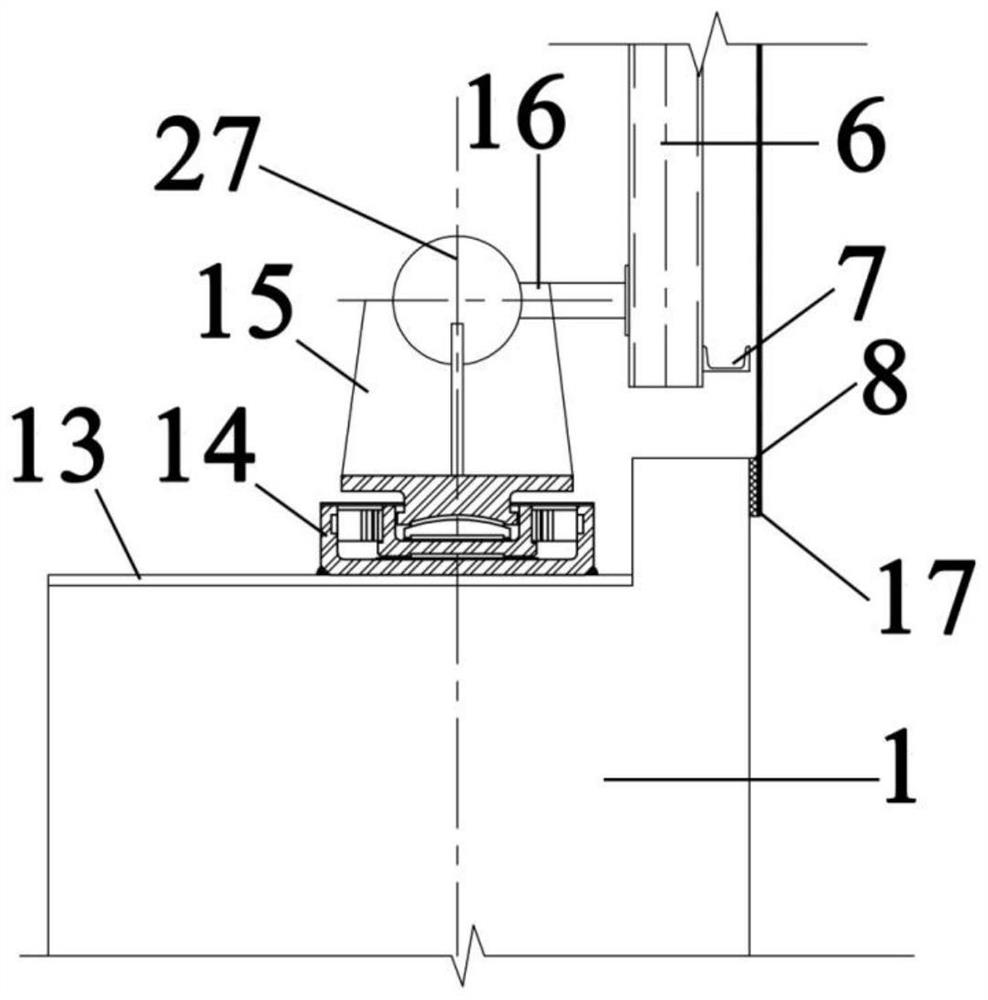

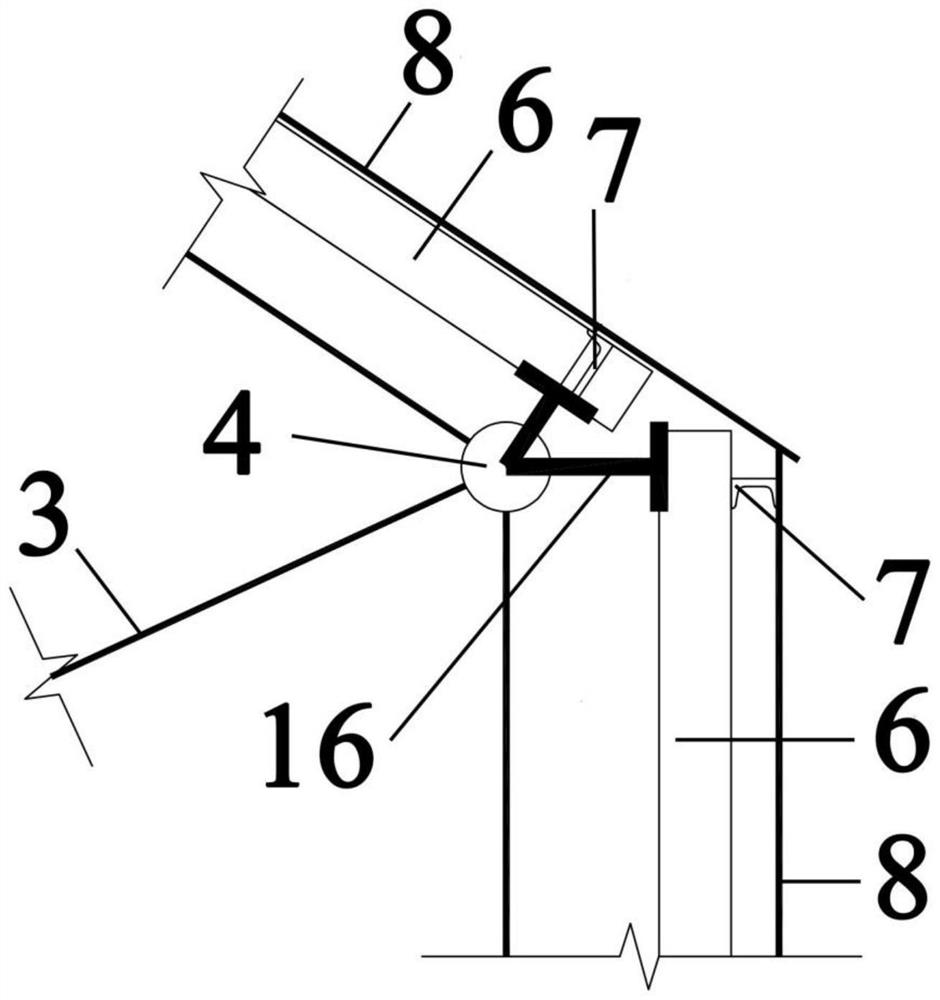

[0057] The clinker silo steel roof structure in which welded balls and bolt balls are used in combination in this embodiment includes the clinker silo roof round platform grid and the roof room structure, and the clinker silo top round platform grid includes the clinker silo grid support 2 , round steel pipe 3, bolt ball joint 4, welded ball joint 27, main purlin 6, secondary purlin 7, checkered steel plate 8, support 16 and rock wool 17; clinker storage grid support includes embedded parts 13, elastic support Block 14 and clinker storehouse support gusset plate 15; storehouse roof structure includes H-shaped steel beam 5 at the floor level of storehouse roof, H-shaped steel column structure of storehouse roof, H-shaped steel beam-column connection node of storehouse roof, storehouse The hoop ring H-shaped steel beam 26 and the bolt ball 18 with welded H-beam. Inter-column supports 20, stiffeners 22 and high-strength bolts 24, H-shaped steel beam-column connection nodes of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com