Cross-linked water-based coating of thermo-sensitive paper, thermo-sensitive paper and preparation method of thermo-sensitive paper

A water-based coating and heat-sensitive paper technology, applied in the direction of copying/marking methods, coatings, paper coatings, etc., can solve the problems of non-yellowing and solvent-resistant protective effects, expensive cross-linked coatings, long curing time, etc., to achieve excellent Color stability, good anti-yellowing effect, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

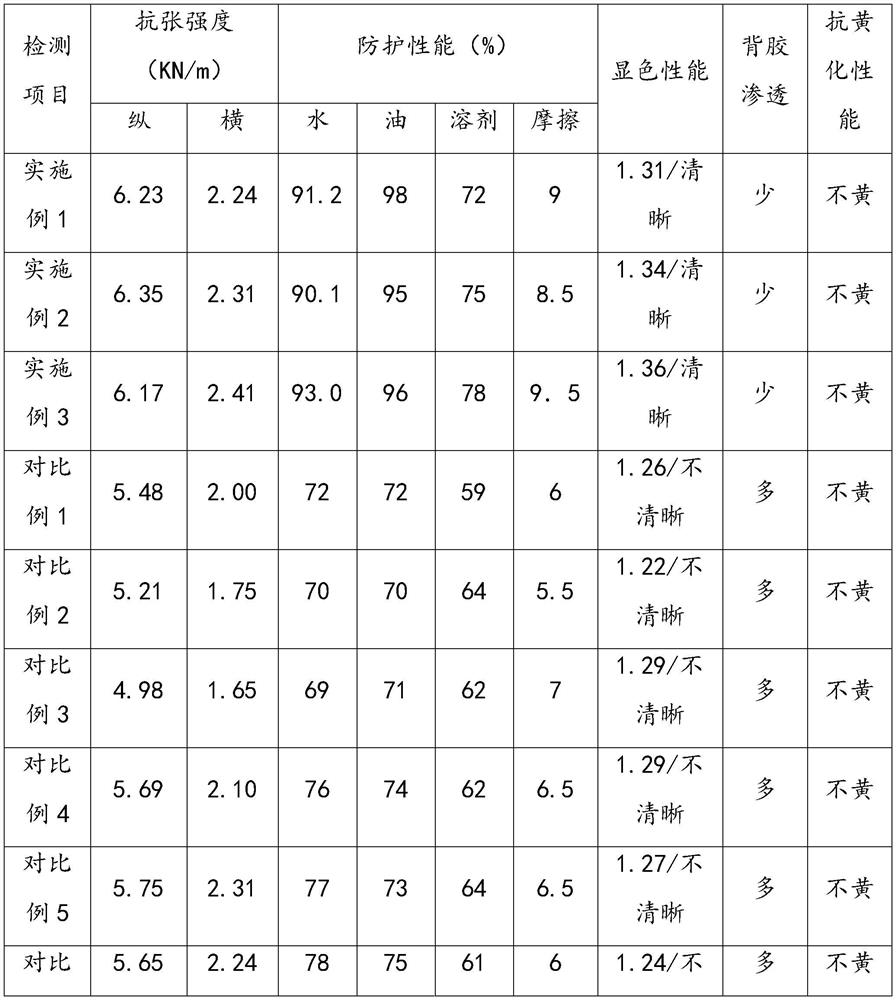

Embodiment 1

[0023] A cross-linked water-based coating for heat-sensitive paper, including a heat-sensitive paint layer coated on the base paper surface, the total coating weight of the heat-sensitive paint layer is 6g / m 2 , and it includes the A liquid layer, the B liquid layer and the C liquid layer stacked in sequence from the base paper in the order of near and far, adjust the pH value of the A liquid layer raw material to (5.5±0.5), and the B liquid layer raw The raw materials of the C liquid layer are laminated and coated on the paper base material by the film transfer method / curtain coating method in sequence from near to far, and the production speed of the coating is (700±100)m / min. After calendering and drying Instantly.

[0024] Among them, the preparation raw materials of A liquid layer include 35g light calcium carbonate, 10g thermoplastic pigment, 40g modified corn starch, 10g polyvinyl alcohol, 10g water-soluble chitosan copolymer and 15g crosslinking agent A, water-soluble ...

Embodiment 2

[0028] A cross-linked water-based coating for heat-sensitive paper, including a heat-sensitive paint layer coated on the base paper surface, the total coating weight of the heat-sensitive paint layer is 15g / m 2 , and it includes the A liquid layer, the B liquid layer and the C liquid layer stacked in sequence from the base paper in the order of near and far, adjust the pH value of the A liquid layer raw material to (5.5±0.5), and the B liquid layer raw And C liquid layer raw materials are sequentially laminated and coated on the paper base material by air knife coating method / curtain coating method from near to far, and the production speed of coating is (500±100)m / min. It can be obtained after calendering and drying.

[0029] Among them, the preparation raw materials of A liquid layer include 35g light calcium carbonate, 10g thermoplastic pigment, 40g modified corn starch, 10g polyvinyl alcohol, 10g water-soluble chitosan copolymer and 15g crosslinking agent A, water-soluble ...

Embodiment 3

[0033] A cross-linked water-based coating for heat-sensitive paper, including a heat-sensitive paint layer coated on the base paper surface, the total coating weight of the heat-sensitive paint layer is 10g / m 2, and it includes the A liquid layer, the B liquid layer and the C liquid layer stacked in sequence from the base paper in the order of near and far, adjust the pH value of the A liquid layer raw material to (5.5±0.5), and the B liquid layer raw And C liquid layer raw materials are sequentially laminated from near to far and coated on the paper base material by casting method / curtain coating method. The production speed of coating is (600±100)m / min, calendering Ready to serve after drying.

[0034] Wherein, the preparation raw material of A liquid layer comprises 40g thermoplastic pigment, 20g modified cornstarch, 20g polyvinyl alcohol, 30g water-soluble chitosan copolymer and 10g crosslinking agent A, and water-soluble chitosan copolymer is specifically chitosan Sugar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com