Method of filling fast excavation tunnel with hydrofracturing chemical expanding agent

A chemical expansion agent, hydraulic fracturing technology, applied in tunnels, earth-moving drilling, mining fluids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below.

[0020] A method for filling a rapid excavation roadway with a hydraulic fracturing chemical expansion agent is implemented, and the method is carried out according to the following steps.

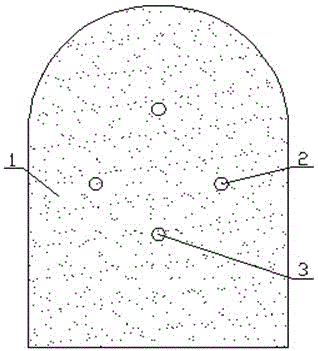

[0021] Step 1. Drill four holes on the excavation surface with a distance of 20-30m from the working face by using the water-exploring drill. The depth is about 100-500m. There are two main purposes of drilling, one is to explore water in advance, and the other is described in the following steps.

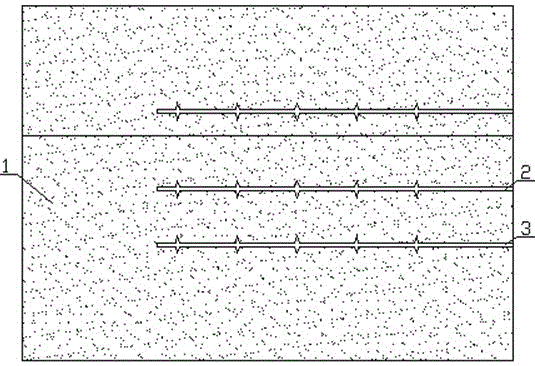

[0022] Step 2. Use a slotted drill to open a wedge-shaped slot every 4-7m in the edge drilled hole. From the bottom of the hole, the slots are respectively the first, the second, ... until the hole is reached, and the slotted drill is now It is widely used in this field, and its structure and performance are well known to those skilled in the art.

[0023] Step 3. Connect the water injection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solidification time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com