A dual-mode support control system and method

A control system and dual-mode technology, applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve the problems of too late to do steel arch support, low construction safety risk, and less support volume, so as to improve efficiency and The effect of supporting quality, satisfying construction safety, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

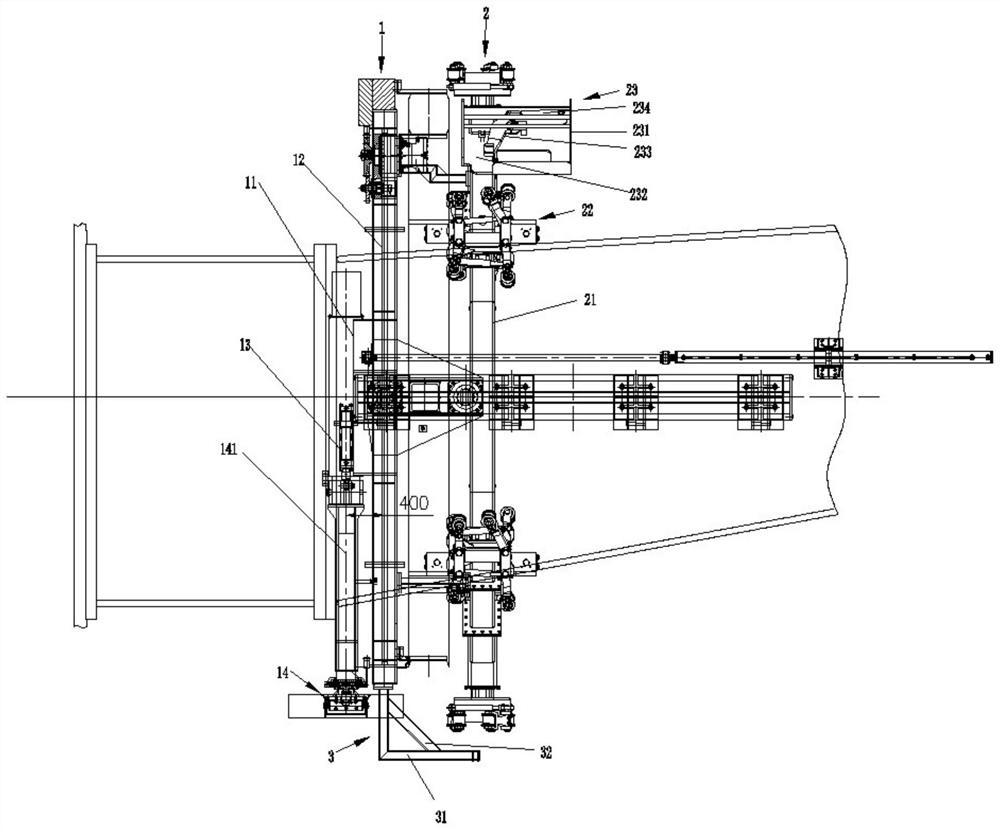

[0041] Such as figure 1 As shown, the dual-mode support control system and method include: a steel formwork assembly unit 1 , a steel arch assembly unit 2 and a steel arch traction device 3 .

[0042] The steel template assembly part 1 is used to drive the steel template to move or rotate, and it includes a fixed ring 11 , a rotating ring 12 , a lifting device 13 and a gripper device 14 .

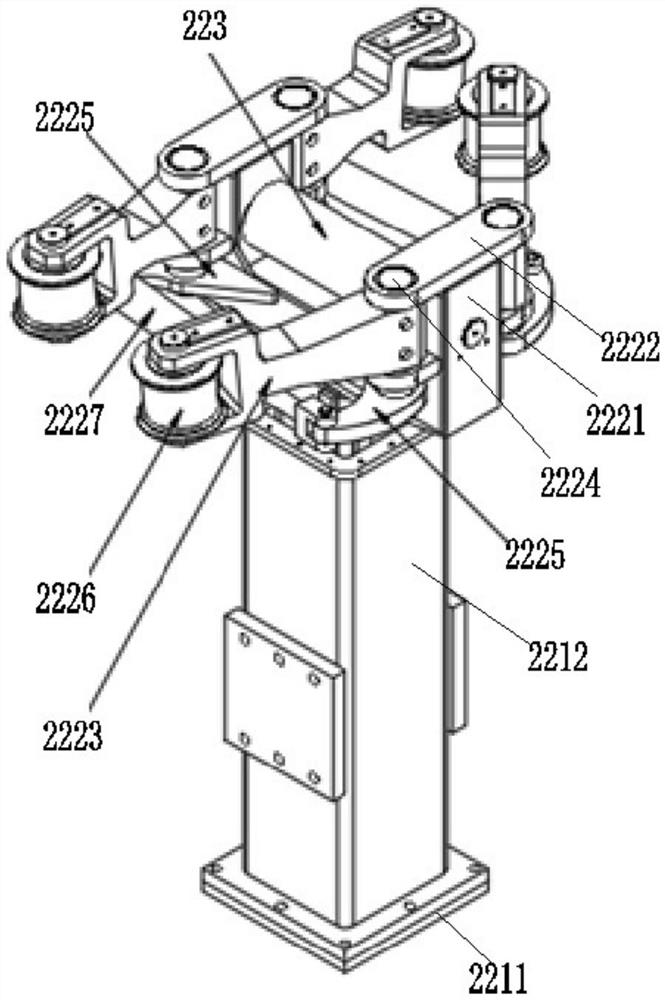

[0043] Such as Figure 4As shown in / 5, the gripper device 14 includes a gripper frame 141; the first gripper rotating shaft 142, which is rotatably connected to the gripper frame 141; the installation box 143, which is fixedly connected with the first gripper rotating shaft 142; Oil cylinder 144, which is used to promote the installation box 143 to rotate around the first gripper shaft 142, its two ends are rotatably connected to the first extension frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com