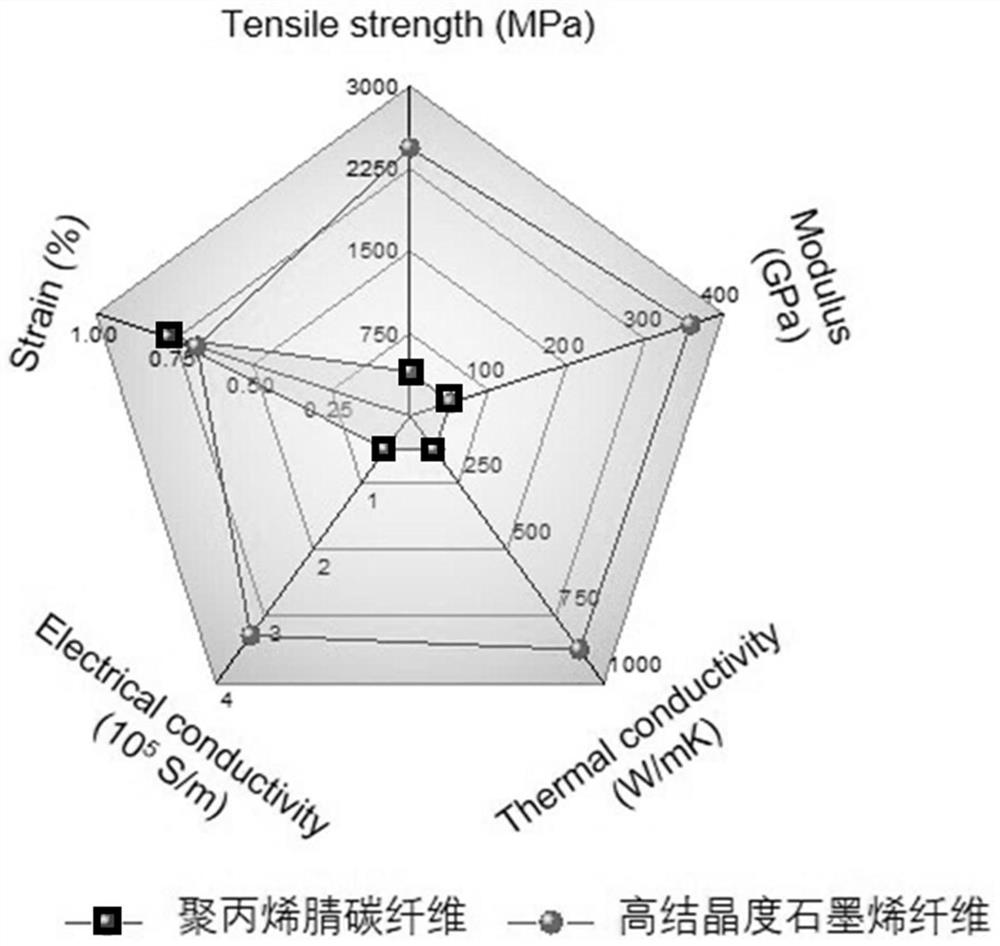

Preparation method of graphene fiber with high graphite crystallinity

A high-crystallinity, carbonaceous fiber technology, applied in the field of nanomaterials, can solve the problems of graphene with low degree of oxidation and low structural defects, unfavorable molding processing, and difficulty in orientation, so as to reduce internal defects in fibers and reduce production costs. , reduce the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

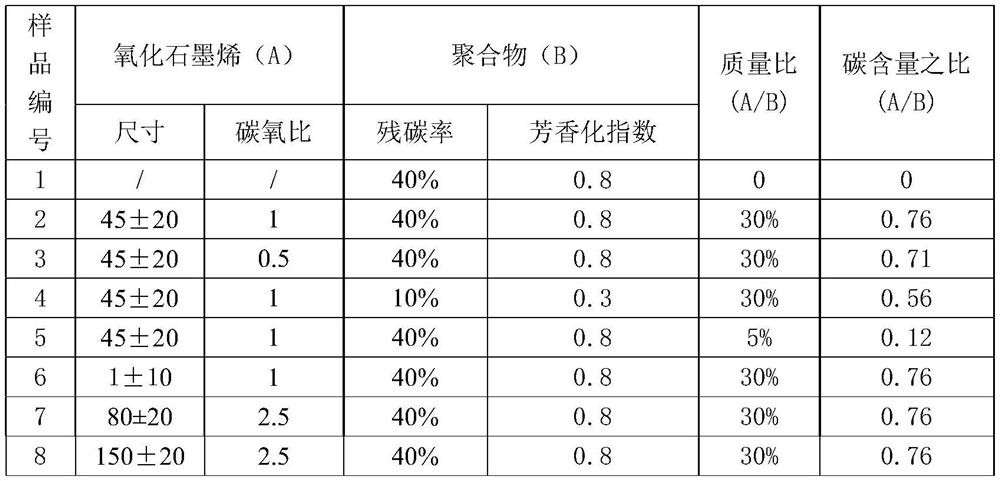

[0026] The present embodiment adopts one-dimensional linear polymer polyacrylonitrile (its residual carbon rate is 30%, aromatization index is 0.8) to prepare carbon fiber, has studied the parameter (see table 1) of the two-dimensional lamellar seed crystal used for induction The impact on its performance is as follows:

[0027] (1) Evenly disperse polyacrylonitrile in pure DMF solution, add graphene oxide to form a spinning solution, and the solid content of the system is 5%.

[0028] (2) Extrude the liquid crystal composite spinning solution into a coagulation bath of pure ethyl acetate, and obtain high crystallinity composite precursor fibers through a wet liquid crystal spinning process. Maintain a proper draft force of 5N during the spinning process.

[0029] (3) Place the raw silk in a tube furnace, heat it up to 2000°C for 3 hours, and treat it with an air pressure of 10 MPa.

[0030] Table 1

[0031]

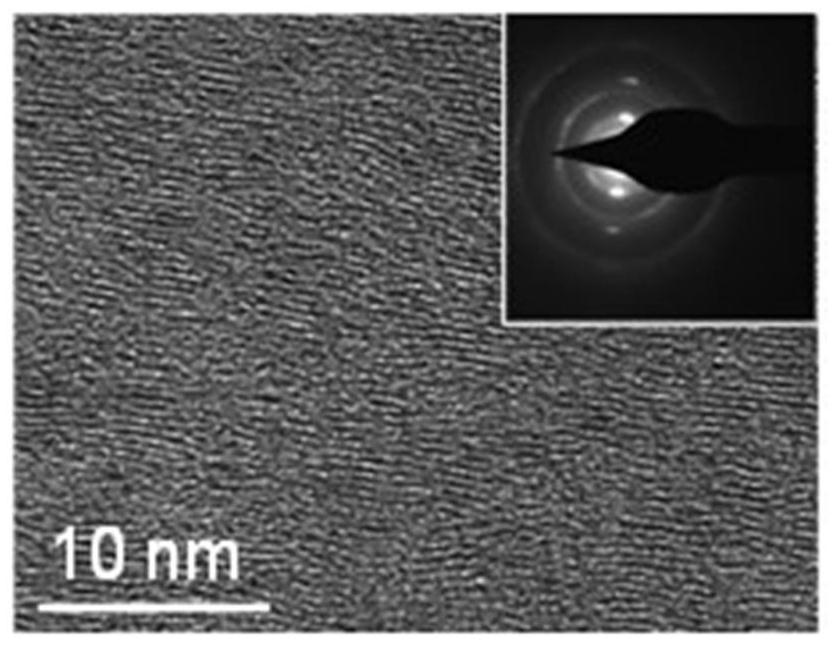

[0032] Through the wide-angle X-ray diffraction test, the cry...

Embodiment 2

[0042] In this embodiment, different one-dimensional linear polymers (with different carbon residue rates and aromatization indices) are used to prepare carbon fibers, as shown in Table 3, as follows:

[0043] (1) Uniformly disperse the one-dimensional linear polymer in pure DMSO solution, add graphene oxide to form a spinning solution, and the solid content of the system is 10%. The size of graphene oxide is 45±20 microns, and the carbon-to-oxygen ratio is 2.5; the ratio of the carbon content of the two-dimensional flake crystal seed to the carbon content of the polymer is controlled at 0.76±0.02; the solid content of the mixed solution is 5 mg / g.

[0044] (2) Extrude the liquid crystal composite spinning solution into a coagulation bath of pure ethyl acetate, and obtain high crystallinity composite precursor fibers through a wet liquid crystal spinning process.

[0045] (3) Put the raw silk in a tube furnace, heat it up to 2000° C. or more, and heat it with an air pressure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com