High-strength and high-toughness steel as well as preparation method and application thereof

A high-toughness steel and high-strength technology, applied in the field of high-strength high-toughness steel and its preparation, can solve the problems of difficulty in popularization, low-temperature impact toughness of hot-rolled plates, and inability to meet the demand for anti-detonation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

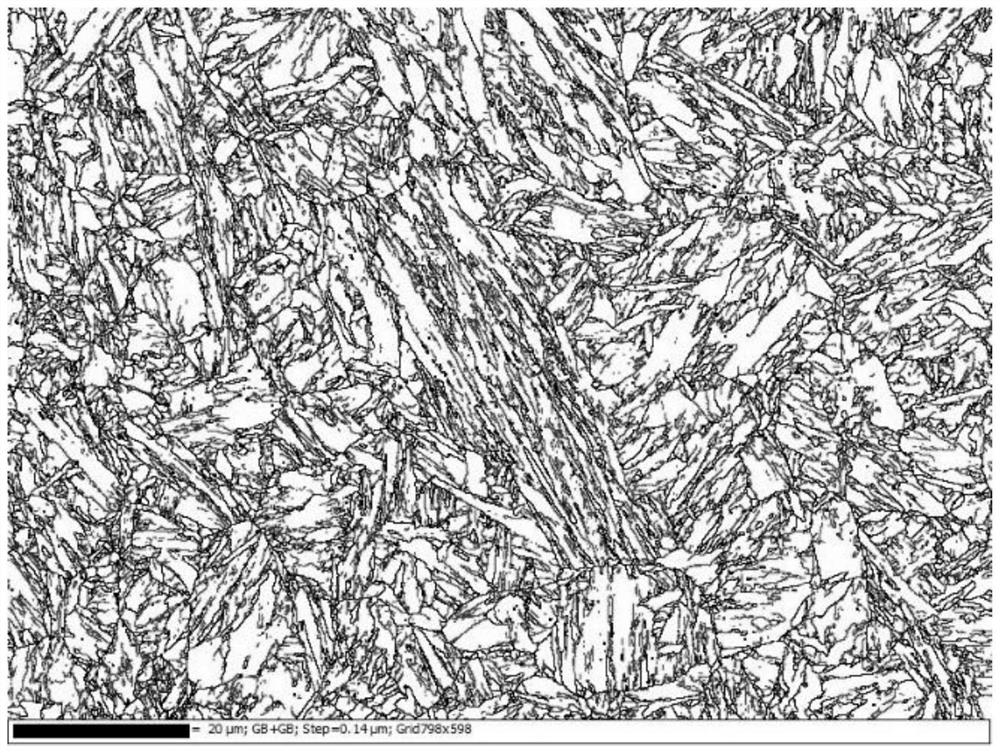

Image

Examples

preparation example Construction

[0059] The present invention provides a method for preparing high-strength and high-toughness steel described in the above technical solution, comprising the following steps:

[0060] (1) Smelting and pouring the raw materials in sequence to obtain steel billets;

[0061] (2) homogenize the billet obtained in the step (1) to obtain a soaking billet;

[0062] (3) Rough rolling and finishing rolling are carried out successively to the soaking steel slab obtained in said step (2), to obtain a rolled steel slab;

[0063] (4) Quenching and low-temperature tempering are sequentially performed on the rolled steel slab obtained in the step (3) to obtain high-strength and high-toughness steel.

[0064] In the invention, the raw materials are smelted and poured in sequence to obtain steel slabs.

[0065] The present invention has no special limitation on the specific types and sources of the raw materials, as long as the components of the high-strength and high-toughness steel can mee...

Embodiment 1

[0084] A high-strength and high-toughness steel with a yield strength of 1100MPa, which is composed of the following components in terms of mass percentage:

[0085] C: 0.16%; Mn: 0.61%; Si: 0.27%; Cr: 0.75%; Ni: 0.95%; Mo: 0.23%; V: 0.107%; Ti: 0.020%; B: 0.0015%; P≤0.020%; S≤0.005% and the balance of iron;

[0086] The preparation method of the high-strength and high-toughness steel consists of the following steps:

[0087] (1) Use primary smelting furnace and LF refining furnace to smelt the raw materials in turn, and then cast to obtain billets; the cooling method of the pouring is stacking and slow cooling;

[0088] (2) Homogenize the steel slab obtained in the step (1) to obtain a soaking slab; the heat preservation temperature of the homogenization treatment is 1220°C, and the heat preservation time of the homogenization treatment is 3h;

[0089] (3) Rough rolling and finishing rolling are carried out successively to the soaking billet obtained in the step (2), to obt...

Embodiment 2

[0093] A high-strength and high-toughness steel with a yield strength of 1100MPa, which is composed of the following components in terms of mass percentage:

[0094] C: 0.20%; Mn: 0.55%; Si: 0.30%; Cr: 0.85%; Ni: 0.57%; Mo: 0.26%; V: 0.10%; Ti: 0.023%; B: 0.0023%; P≤0.020%; S≤0.01% and the balance of iron;

[0095] The preparation method of the high-strength and high-toughness steel consists of the following steps:

[0096] (1) Use primary smelting furnace and LF refining furnace to smelt the raw materials in turn, and then cast to obtain billets; the cooling method of the pouring is stacking and slow cooling;

[0097] (2) Homogenize the steel slab obtained in the step (1) to obtain a soaking slab; the heat preservation temperature of the homogenization treatment is 1220°C, and the heat preservation time of the homogenization treatment is 3h;

[0098] (3) Rough rolling and finishing rolling are carried out successively to the soaking billet obtained in the step (2), to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com