Resource utilization method of metallic nickel slag

A metal nickel and resource utilization technology, applied in the direction of chemical instruments and methods, non-metallic elements, sulfur compounds, etc., can solve the problem of insufficient utilization of slag waste heat resources, comprehensive recovery of metal elements, failure to realize comprehensive consideration of remaining tailings utilization, and metal iron Poor quality and other problems, to achieve the effect of high nickel slag treatment efficiency, low production cost, and high total output value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the following description, for the purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It will be apparent, however, that the embodiments may be practiced without these specific details.

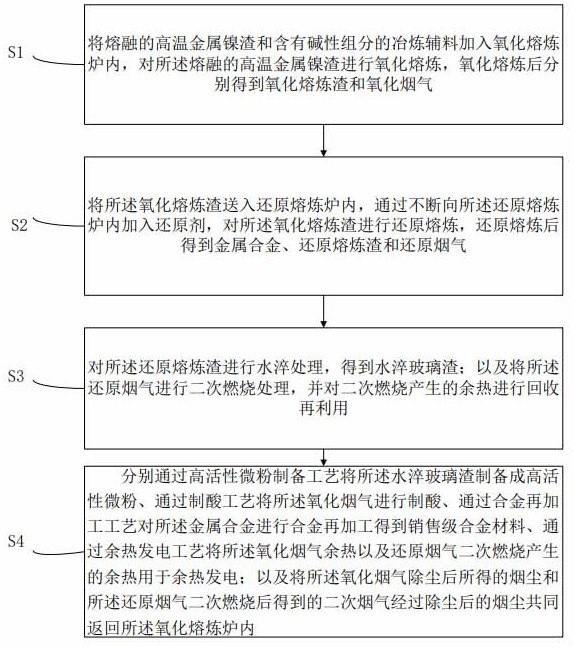

[0044] In view of the current existing nickel-iron slag processing technology proposed above, the utilization of slag waste heat resources is not comprehensive enough, the metal element recovery requires secondary heating, the energy consumption is high, the cost is high, and S will also be reduced into metal. In iron, the quality of metal iron is poor, the utilization of residual tailings has not been comprehensively considered, and the economy is poor. A method for resource utilization of metal nickel slag is proposed.

[0045] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0046] In order to illustrate the reso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com