Graphene composite heat dissipation coating and preparation method thereof, and heat dissipation adhesive tape and preparation method thereof

A graphene composite and heat-dissipating coating technology, which is applied in coatings, adhesives, adhesive types, etc., can solve the problem that heat-dissipating materials cannot meet the high heat dissipation requirements of electronic equipment, and achieve improved electrical conduction and heat dissipation performance, high thermal conductivity, and high efficiency. The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a kind of preparation method of graphene composite heat-dissipating paint, comprises the following steps:

[0047] (1) Mix C60, graphene, and heat conducting powder, carry out hydrothermal reaction, then carry out room temperature drying, freezing, and room temperature drying to the product successively to obtain graphene composite heat dissipation powder;

[0048] (2) After mixing the silicone-modified acrylic resin and additives, adding graphene composite heat dissipation powder, water, and dispersant to adjust the viscosity to obtain graphene composite heat dissipation coating.

[0049]In the present invention, the temperature of the hydrothermal reaction in step (1) is preferably 120-180°C, more preferably 126-171°C, more preferably 154°C; the time of the hydrothermal reaction is preferably 8-12h, more preferably 9-11h, more preferably 10h.

[0050] In the present invention, the drying time at room temperature in step (1) is inde...

Embodiment 1

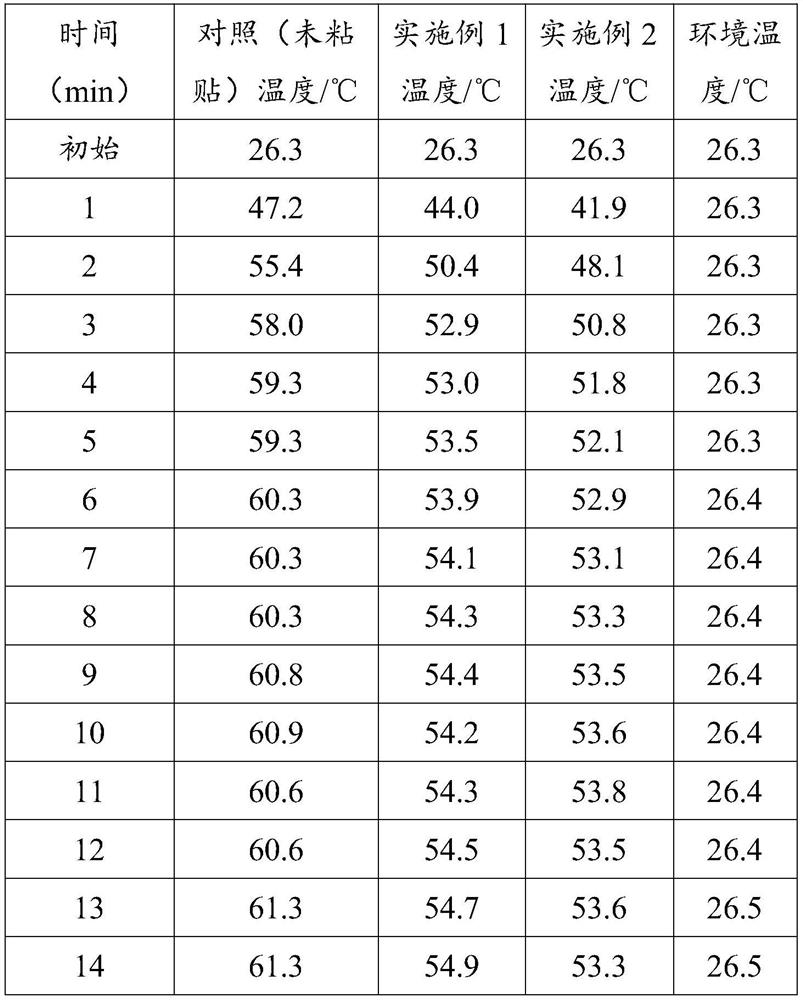

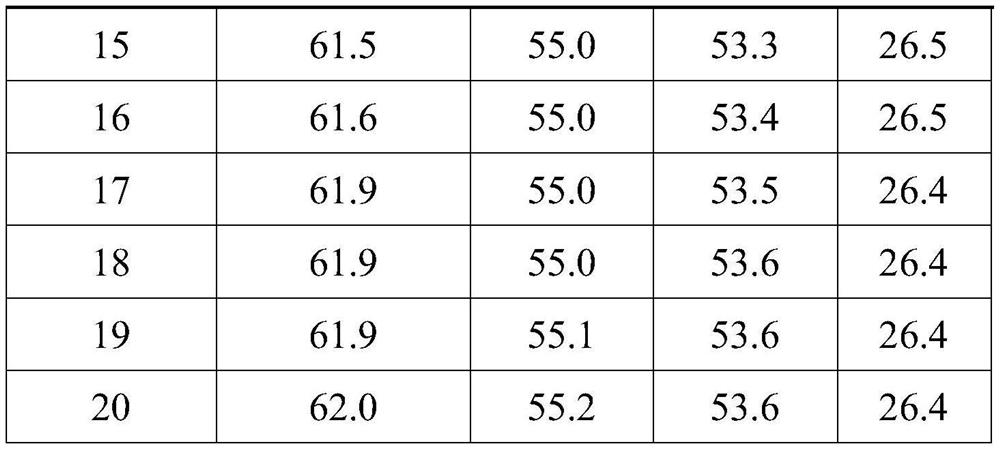

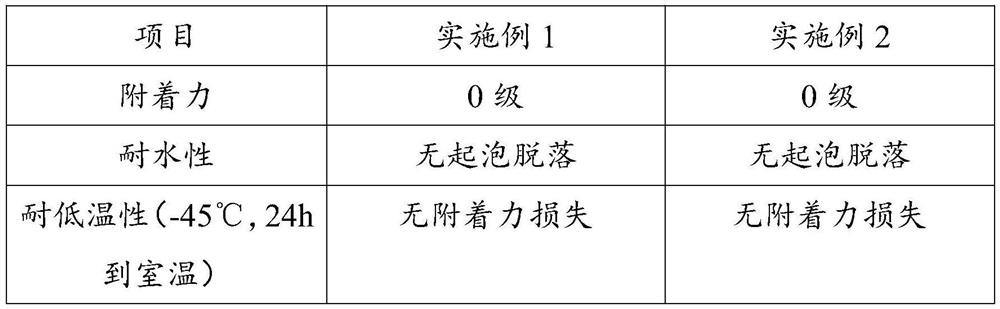

[0075] This embodiment provides a heat dissipation adhesive tape, the preparation method of which comprises the following steps:

[0076] (1) 1 part of C60, 5 parts of graphene oxide, 0.5 parts of Al 2 o 3 (Particle size is 40nm) mixed with 0.5 parts of SiC (particle size is 40nm), hydrothermally reacted at 160°C for 9h, then the product was dried at room temperature for 8h, frozen at -20°C for 48h, and dried at room temperature for 8h to obtain graphene composite heat dissipation pink;

[0077] (2) 8 parts of graphene composite cooling powder, 35 parts of water, 0.5 parts of KH560 were ultrasonically dispersed for 2 hours to obtain graphene slurry; Stir at 1100r / min for 20min, then add graphene slurry, stir at 1500r / min for 60min, and adjust the viscosity to 900mpa.s with water to obtain a graphene composite heat-dissipating coating;

[0078] (3) 35 parts of TPU and 2 parts of Si 3 N 4 (Particle size is 10μm) mixing, under the condition of vacuum degree of -0.06MPa, vacu...

Embodiment 2

[0080] This embodiment provides a heat dissipation adhesive tape, the preparation method of which comprises the following steps:

[0081] (1) 2 parts of C60, 5 parts of graphene oxide, 1.5 parts of Al 2 o 3 (particle size is 30nm) and 0.5 parts of SiC (particle size is 30nm) mixed, hydrothermal reaction at 140°C for 12h, and then the product is dried at room temperature for 8h, -20°C for 48h, and room temperature for 8h to obtain graphene composite heat dissipation pink;

[0082] (2) Ultrasonic disperse 7 parts of graphene composite cooling powder, 35 parts of water, and 0.5 parts of sodium polyacrylate for 2 hours to obtain graphene slurry; mix 15 parts of silicone-modified acrylic resin, 0.02 parts of BYK028, and 0.02 parts of Digo 245 Stir at 1500r / min for 30min, then add graphene slurry, stir at 1600r / min for 90min, and adjust the viscosity to 1000mpa.s with water to obtain a graphene composite heat-dissipating coating;

[0083] (3) 35 parts of silicone modified acrylic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com