Curing agent, preparation method thereof and application of curing agent in preparation of polyacrylate pressure-sensitive adhesive

A technology of polyacrylates and curing agents, which is applied in the direction of adhesive types, adhesive additives, polymer adhesive additives, etc., and can solve pressure-sensitive adhesives with high hardness, high degree of crosslinking, and poor adhesive performance. problem, to achieve the effect of increasing cost burden, good biodegradability and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

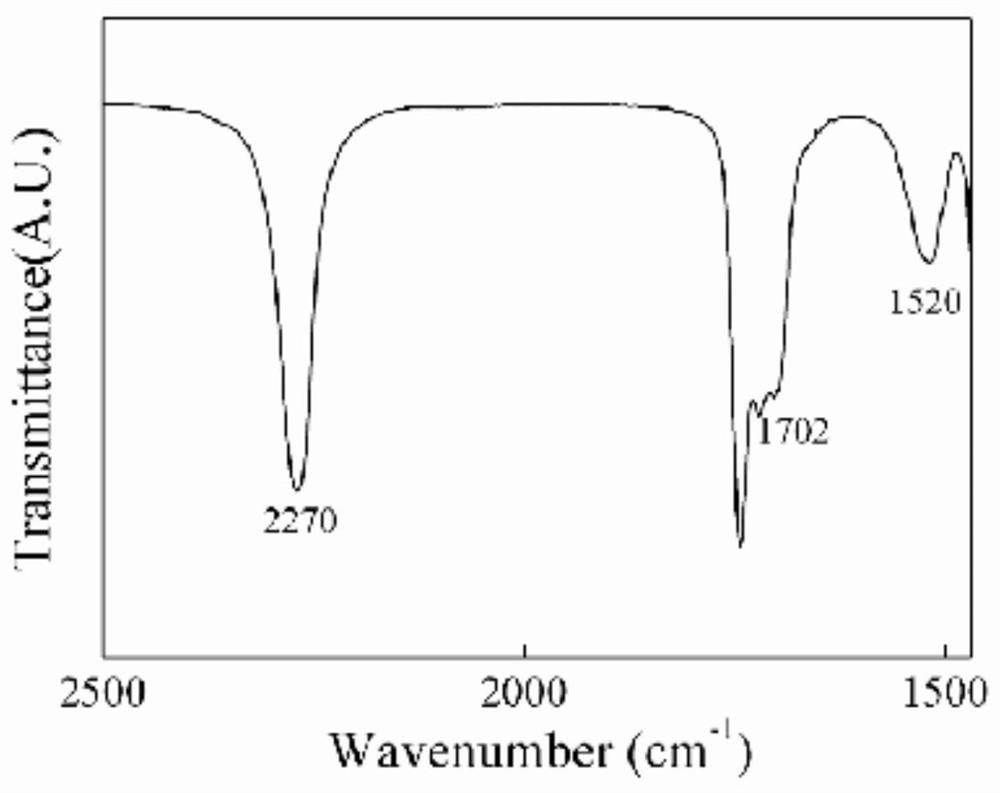

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific examples.

[0028] The following are the structural formulas of reactant 1 and reactant 2 in Table 1.

[0029]

[0030] Table 1 Embodiment and comparative example

[0031]

[0032]

[0033] All chemical substances in the above table were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.

[0034] Monomer molar ratio: molar ratio of isocyanate / active hydrogen atom-containing compound

[0035] In the above table, reactant 1 is a compound containing an active hydrogen atom, and reactant 2 is a diisocyanate, as follows:

[0036] MG: Glyceryl monostearate

[0037] OG: Glyceryl monooleate

[0038] CO: castor oil

[0039] BS: butanediol / succinic acid dimer

[0040] BA: butanediol / adipic acid dimer

[0041] GG: Glyceryl Glycerides

[0042] GAG: Glyceryl Glutamate

[0043] TDI: Toluene diisocyanate

[0044] MDI: diphenylmethane diisocyanate

[0045] HDI:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com