Industrial flue gas solid waste recycling drying-free curing material and application

A technology for curing materials and industrial flue gas, applied in the field of industrial flue gas pollution control, can solve the problems of affecting the permeability of the sintered material layer, unable to return to the furnace, etc., to achieve pollution control and environmental protection, promote molding curing rate, and later strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

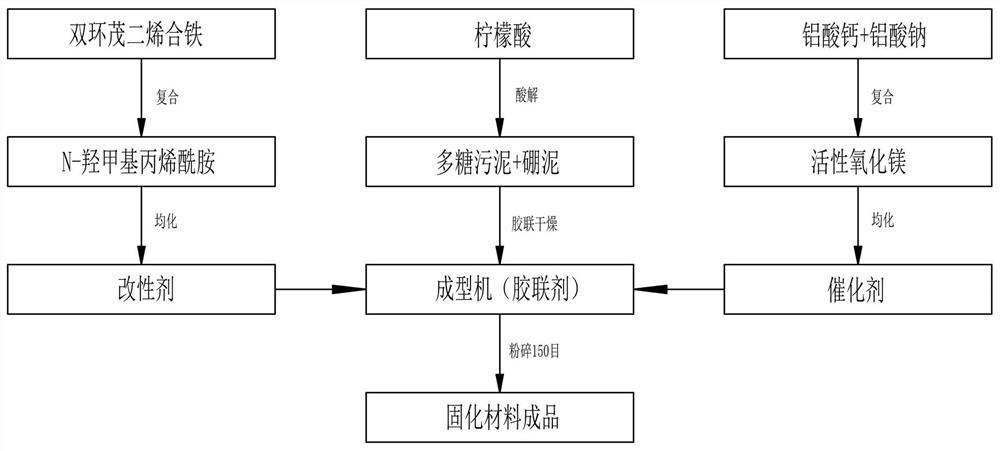

Method used

Image

Examples

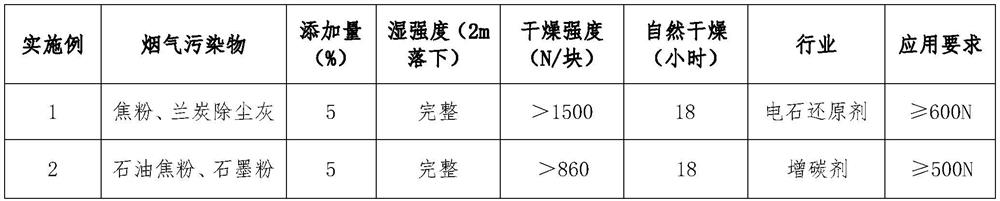

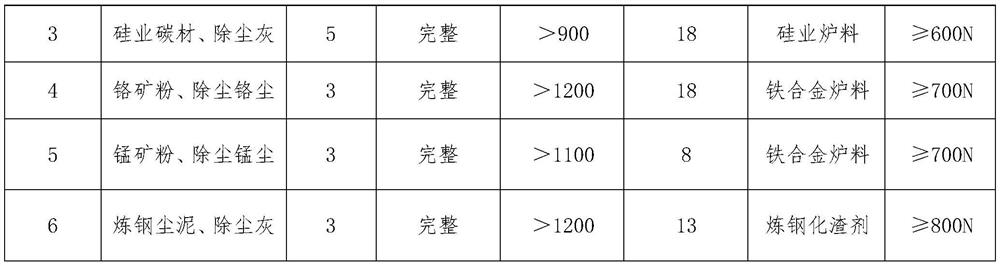

Embodiment 1

[0035] A drying-free solidification material for recycling industrial flue gas solid waste and its application, which is composed of 50% forming agent, 10% modifying agent and 40% catalyst. The preparation method is as follows: the above-mentioned raw materials are input into a mixer according to the proportion and mixed evenly, and then crushed to 150 mesh by a pulverizer to obtain a solid waste solidified material product.

[0036] The application of the present invention includes the following steps: adding 95% of the solid waste (coke powder, blue charcoal powder) and 5% of the solidified material into the mixing homogenizer for mixing and homogenizing; sending the homogenized mixture into the forced mixer for grinding Stirring; send the stirred mixture into a high-pressure molding machine to form agglomerates, which can be used as auxiliary materials and raw materials for reducing agents in calcium carbide plants after 18 hours of natural curing. The test results are show...

Embodiment 2

[0038] A drying-free solidification material for recycling industrial flue gas solid waste and its application, which is composed of 40% of forming agent, 10% of modifying agent and 50% of catalyst. The preparation method is as follows: the above-mentioned raw materials are input into a mixer according to the proportion and mixed evenly, and then crushed to 150 mesh by a pulverizer to obtain a solid waste solidified material product.

[0039] The application of the present invention includes the following steps: adding 95% of the solid waste (coke powder, blue charcoal powder) and 5% of the solidified material into the mixing homogenizer for mixing and homogenizing; sending the homogenized mixture into the forced mixer for grinding Stirring; send the stirred mixture into a high-pressure molding machine to form agglomerates, which can be used as auxiliary materials and raw materials for reducing agents in calcium carbide plants after 18 hours of natural curing. The test results...

Embodiment 3

[0041] A drying-free solidification material for recycling industrial flue gas solid waste and its application, which is composed of 45% forming agent, 5% modifying agent and 45% catalyst. The preparation method is as follows: the above-mentioned raw materials are input into a mixer according to the proportion and mixed evenly, and then crushed to 150 mesh by a pulverizer to obtain a solid waste solidified material product.

[0042] The application of the present invention includes the following steps: adding 95% of the solid waste (coke powder, blue charcoal powder) and 5% of the solidified material into the mixing homogenizer for mixing and homogenizing; sending the homogenized mixture into the forced mixer for grinding Stirring; send the stirred mixture into a high-pressure molding machine to form agglomerates, which can be used as auxiliary materials and raw materials for reducing agents in calcium carbide plants after 18 hours of natural curing. The test results are shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com