In-situ remediation agent for underground water chlorinated hydrocarbon pollution, preparation method and application

A technology for in-situ remediation and remediation agents, which is applied in the restoration of polluted soil, water pollutants, and contaminated groundwater/leachate treatment, etc. Achieve the effect of accelerating rapid degradation, maintaining long-term activity and stability, and achieving rapid proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

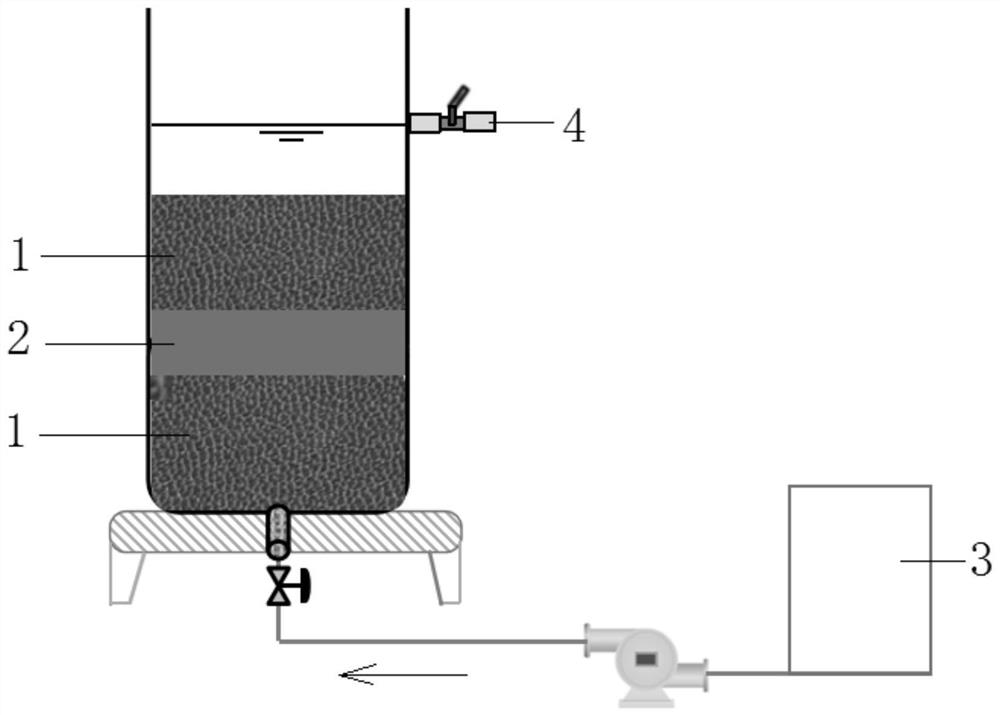

[0042] The laboratory weighed 35g of tap water, 10g of reusable oil, and 1g of emulsifier, mixed and stirred well, then added 41g of zero-valent iron powder with a particle size of 20um, 8g of biochar, and 0.1g of gum arabic powder, mixed well, and then added industrial 3g of syrup and 2g of corn stalk powder were mixed for 5 to 10 minutes at a stirring speed of 2000r / min to make a restoration agent slurry. The prepared restoration agent slurry is uniform and stable. The laboratory is equipped with 100mL of 2mg / L trichlorethylene (TCE) solution, and 5g of the prepared restoration agent is added under the protection of nitrogen. The effective iron powder content is 1.5%, and it is kept in a dark seal. Regularly measure changes in oxidation-reduction potential (ORP), dissolved oxygen (DO) and pH in water. The results showed that ORP dropped from -50mv to -350mV within 5 days, DO dropped below 0.4ppm, and the pH value was 7.35~7.46. The value remains at around 7.49. This shows ...

Embodiment 2

[0044] The laboratory weighed 35g of tap water, 15g of reusable oil, and 2g of emulsifier, mixed and stirred well, then added 20g of zero-valent iron powder with a particle size of 20um, 12.5g of biochar, and 0.5g of gum arabic powder, mixed well, and then added 5g of industrial syrup and 10g of corn stalk powder were mixed for 5-10min at a stirring speed of 2000r / min to make a restoration agent slurry. The prepared restoration agent slurry is uniform and stable. The laboratory is equipped with 100mL of 2mg / L trichlorethylene (TCE) solution, and 5g of the prepared restoration agent is added under nitrogen protection. The effective iron powder content is 1.5%, and it is sealed and kept in the dark. Regularly measure changes in oxidation-reduction potential (ORP), dissolved oxygen (DO) and pH in water. The results showed that ORP dropped from -50mv to -310mV within 5 days, DO dropped below 1ppm, and the pH value was 7.18-7.26. Maintained at around 7.62. This shows that the add...

Embodiment 3

[0046] The laboratory weighed 15g of tap water, 15g of reusable oil, and 2g of emulsifier, mixed and stirred well, then added 45g of zero-valent iron powder with a particle size of 50um, 8g of biochar, and 0.3g of gum arabic powder, mixed well, and then added industrial 5g of syrup and 9.7g of corn stalk powder were mixed for 5 to 10 minutes at a stirring speed of 2000r / min to prepare a restoration agent slurry. The prepared restoration agent slurry is uniform and stable. The laboratory is equipped with 100mL of 2mg / L trichlorethylene (TCE) solution, and 5g of the prepared compound agent is added under nitrogen protection. The effective iron powder content is 1.5%, and it is sealed and kept in the dark. Regularly measure changes in oxidation-reduction potential (ORP), dissolved oxygen (DO) and pH in water. The results showed that ORP dropped from -50mv to -270mV within 5 days, DO dropped below 1.2ppm, and the pH value was 7.21-7.43. The value remained at around 7.53. This sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com