Abrasive dust collecting and cooling liquid cleaning device

A technology of coolant and abrasive dust, applied in grinding/polishing safety devices, chemical instruments and methods, grinding/polishing equipment, etc. Improve the utilization rate of machine time, the device is simple and efficient, and the effect of subsequent use is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

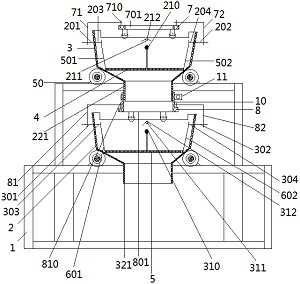

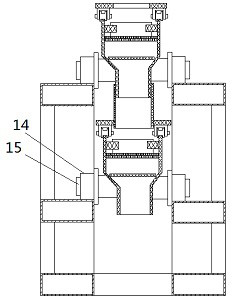

[0021] The grinding debris collection and coolant cleaning device is composed of a stainless steel bracket 1 consisting of upper and lower parts, an open container A3 placed on the upper part of the stainless steel bracket 1, and an open container B2 placed on the lower part of the stainless steel bracket. The two shafts 15 and the four wheels 14 on the two shafts 15 can move on the upper part of the stainless steel support 1, and the open container B2 is on the lower part of the stainless steel support 1 by means of the two shafts 15 at the bottom of the open container B2 and the four wheels 14 on the two shafts 15 It can be moved. The open container A3 has a round through-hole shelf A4 and a beam A210 inside, and the open container B2 has a square through-hole shelf B5 and a beam B310 inside. The open container A3 has a movable upper cover A7 and a movable upper cover A7 There is a soft waterproof cloth C71 at one end, and a soft waterproof cloth D72 at the other end. There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com