Method for preparing superfine titanium powder through magnetized plasma rotating electrode method

A rotating electrode and plasma technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of large average particle size of powder and limited application range, and achieve the effect of good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

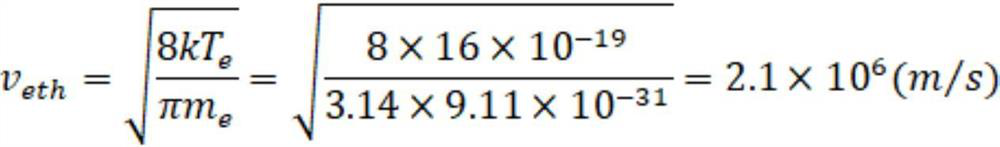

[0020] This embodiment provides a method for preparing ultra-fine titanium powder by a magnetized plasma rotating electrode method, including: adding a magnetic mirror magnetic field with a magnetic induction intensity of 300-500Gs between the electric arc and the rotating electrode in the plasma rotating electrode method. When the electron temperature is about 10eV.

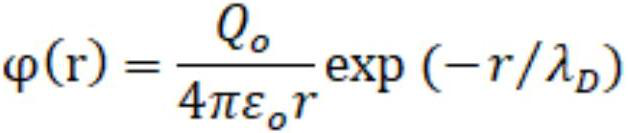

[0021] Since the electron temperature of the plasma is about 10eV, the potential on the surface of the titanium particles is about -10V, which prevents further accumulation of plasma electrons on the surface of the titanium particles. The Debye length of the plasma is λ_D, so the potential distribution of charged titanium particles in the plasma is:

[0022]

[0023] Where r≥Ro, r is the distance from the space point to the center of the titanium particle, Ro is the radius of the titanium particle, is the Debye shielded Coulomb potential of charged titanium particles in the plasma, λ D is the Debye radius ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com