Rolling method of wedge-shaped blank

A wedge-shaped billet and wedge-shaped technology, used in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of poor squareness, low yield and poor shape characteristics of steel plates, and achieve the elimination of width differences and maximum efficiency. , the effect of improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

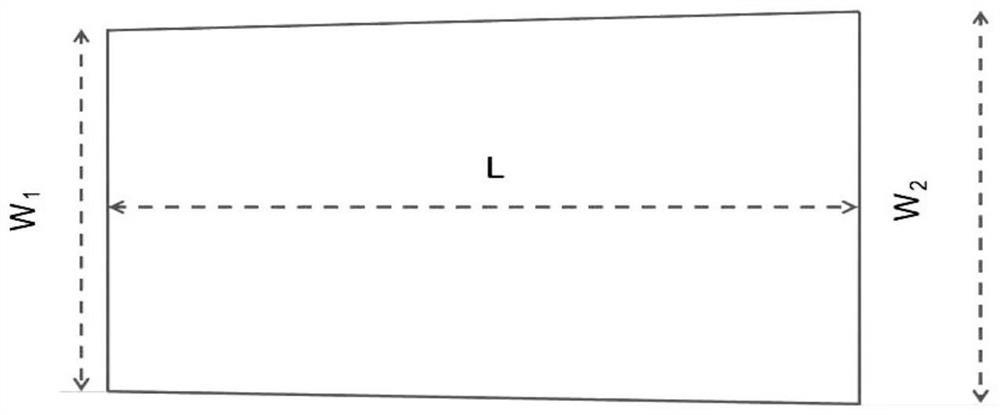

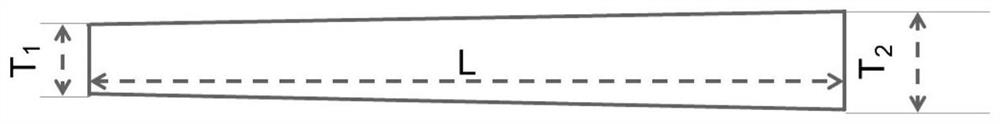

[0017] This embodiment provides a rolling method of a wedge-shaped billet, assuming that the original state of the wedge-shaped billet is that the width of the slab at the small end is W 1 , the slab thickness is T 1 , the width of the big end slab is W 2 , the slab thickness is T 2 , the slab length is L, W 1 2 ,T 1 2 , the rolling target width of the roughing mill is W, and it is characterized in that rolling method comprises the steps:

[0018] (1) Longitudinal rolling to eliminate thickness difference:

[0019] The control rolling mill rolls along the length direction of the wedge-shaped billet to eliminate the thickness difference of the slab and form a slab with uniform thickness.

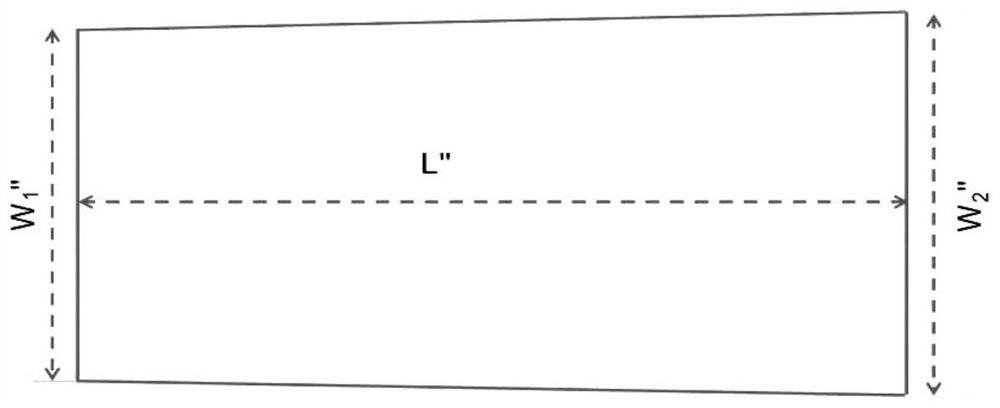

[0020] At this time, the thickness of the slab at the small head end T 1 '=T 1 , Thickness of slab at bulk end T 2 '=T 1 ’, the width of the slab at the small end remains unchanged, W 1 '=W 1 , the width of the large end slab remains unchanged, W 2 '=W 2 , slab length

[0021]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com