Bright anti-corrosion aluminum profile and preparation method thereof

An aluminum profile, bright technology, applied in metal material coating process, electrolytic coating, electrophoretic plating, etc., can solve the problems of large amount of use, long process time, etc., to prevent scratches, reduce use cost, strength and torsion resistance Enough to increase the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a bright anti-corrosion aluminum profile, comprising the following steps:

[0034]S1. bright degreasing, at first operating personnel, bright degreasing solution perfusion is in the inside of degreasing pond, bright degreasing solution is vitriol oil, ammonium bifluoride, citric acid, sodium nitrate, ferric sulfate and dipropylene glycol, and the amount of substance is higher than vitriol oil: Ammonium bifluoride: citric acid: sodium nitrate: ferric sulfate: dipropylene glycol=20:50:6:6:8:10, then the above-mentioned aluminum profiles are placed in the degreasing pool, so that the aluminum profiles are completely immersed in the bright degreasing solution, and heated And control the temperature of the solution in the degreasing tank to 25°C, soak the aluminum profile for 3 minutes, then remove the aluminum profile, then place the aluminum profile in a clear water tank for washing, the washing time is 1 min, and check the aluminum profile after wash...

Embodiment 1

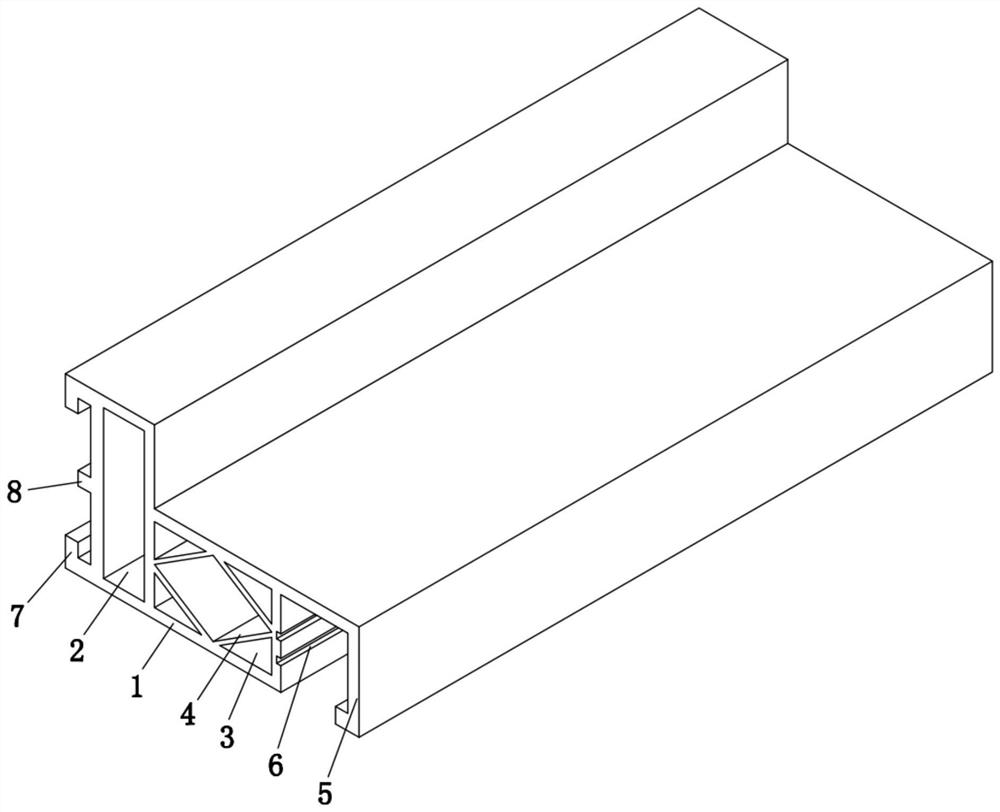

[0047] A bright and anti-corrosion aluminum profile, including a main frame 1, the interior of the main frame 1 is preset with a first cavity 2 and a second cavity 3 distributed in a horizontal structure, and the interior of the second cavity 3 is integrally formed to be ring-shaped There are four reinforcing ribs 4 distributed in the structure, and two adjacent reinforcing ribs 4 are connected end to end, the outer wall of the main frame 1 close to the second cavity 3 is integrally formed with an open edge 5, and the main frame 1 is close to Two hooks 7 are integrally formed on one side of the outer wall of the first cavity 2 and distributed in an up-and-down structure.

[0048] Wherein, a plurality of slide grooves 6 are formed on the outer wall of the main frame 1 close to the open side 5 , and a sliding bar 8 is integrally formed on the outer wall of the main frame 1 close to the hook 7 .

[0049] A method for preparing a bright anti-corrosion aluminum profile, comprising ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com