Modified carbon material and preparation method thereof

A technology of carbon materials and modified carbon, which is applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of limited formaldehyde adsorption capacity, difficult to adsorb formaldehyde, and secondary pollution, so as to improve the adsorption and removal of formaldehyde efficiency, suitable specific surface area, and reasonable pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

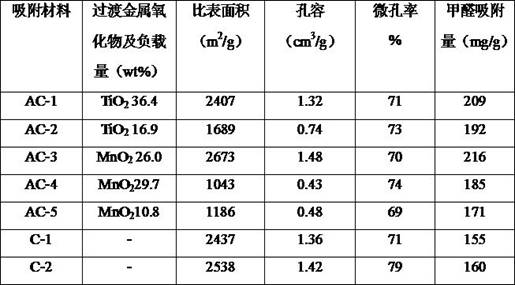

Embodiment 1

[0029]Grind the petroleum coke, potassium hydroxide, and titanium dioxide to a particle size of 20-300 meshes and mix them uniformly in a mass ratio of 1:3:0.2, at a space velocity of 300h -1 Under nitrogen atmosphere, the microwave power is 0.4kW and the temperature is raised to 900°C for activation for 30min. The product is washed with deionized water until the filtrate is neutral, and the obtained solid product is dried at 120°C for 12h to obtain carbon material A1; Airspeed 1800h -1 into CO 2 , reacted at 650°C for 90 minutes to obtain carbon material B1; carbon material B1 was used as the working electrode, graphite was used as the counter electrode, immersed in 0.5wt% HF aqueous electrolyte, voltage 20V, temperature 20 o C, react for 90 minutes, take out the anode product, wash and filter the filtrate with deionized water until the pH value of the filtrate is neutral, and dry in vacuum at 120°C for 12 hours to obtain the modified carbon material AC-1. The properties of ...

Embodiment 2

[0031] Grind the petroleum coke, potassium hydroxide, and titanium dioxide to a particle size of 20-300 meshes and mix them uniformly in a mass ratio of 1:2:0.1, at a space velocity of 200h -1 Under a hydrogen atmosphere, heat up to 850°C for activation for 50 minutes, wash the product with deionized water until the filtrate is neutral, and dry the solid product at 100°C for 18 hours to obtain carbon material A2; put it into carbon material A2 at a space velocity of 1500 hours -1 into CO 2 , reacted at 700°C for 60 minutes to obtain carbon material B2; carbon material B2 was used as the working electrode, graphite was used as the counter electrode, immersed in 0.5% ammonium fluoride ethylene glycol-20% aqueous electrolyte, voltage 10V, temperature 20 o C. After 120 minutes of reaction, the anode product was taken out, washed and filtered with deionized water until the pH of the filtrate was neutral, and vacuum-dried at 130°C for 10 hours to obtain the modified carbon material ...

Embodiment 3

[0033] Grind petroleum coke, potassium hydroxide, and manganese nitrate to a particle size of 20-300 meshes and mix them uniformly in a mass ratio of 1:4:0.23, at a space velocity of 400h -1 Under a nitrogen atmosphere, the microwave power was raised to 950°C for 30 minutes under the condition of a microwave power of 0.4kW, and the product was washed with deionized water until the filtrate was neutral. The obtained solid product was dried at 130°C for 10 hours to obtain carbon material A3; Airspeed 2000h -1 into CO 2 , reacted at 600°C for 120 minutes to obtain carbon material B3; carbon material B3 was used as the working electrode, graphite was used as the counter electrode, immersed in 0.5mol / L sodium sulfate aqueous electrolyte, voltage 10V, temperature 25 o C, reacted for 150 minutes, took out the anode product, washed and filtered with deionized water until the pH of the filtrate was neutral, and dried in vacuum at 150°C for 10 hours to obtain the modified carbon materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com