Frame type competition rifle shooting functional clothing and processing technology thereof

A frame-type, rifle technology, applied in clothing, apparel, protective clothing, etc., can solve the problems of supporting the body and protecting the bone function decline, low strength, insufficient hardness density, etc., to improve body stability, prolong sports life, The effect of reducing fatigue value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

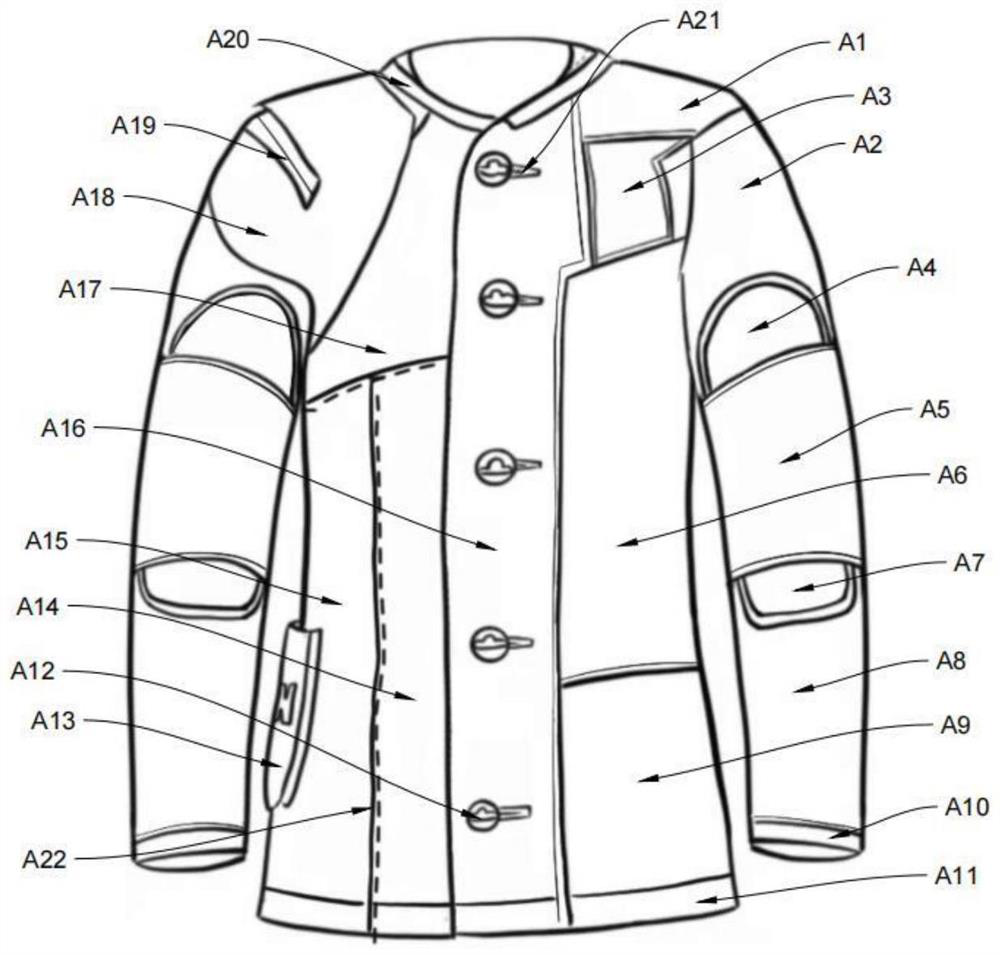

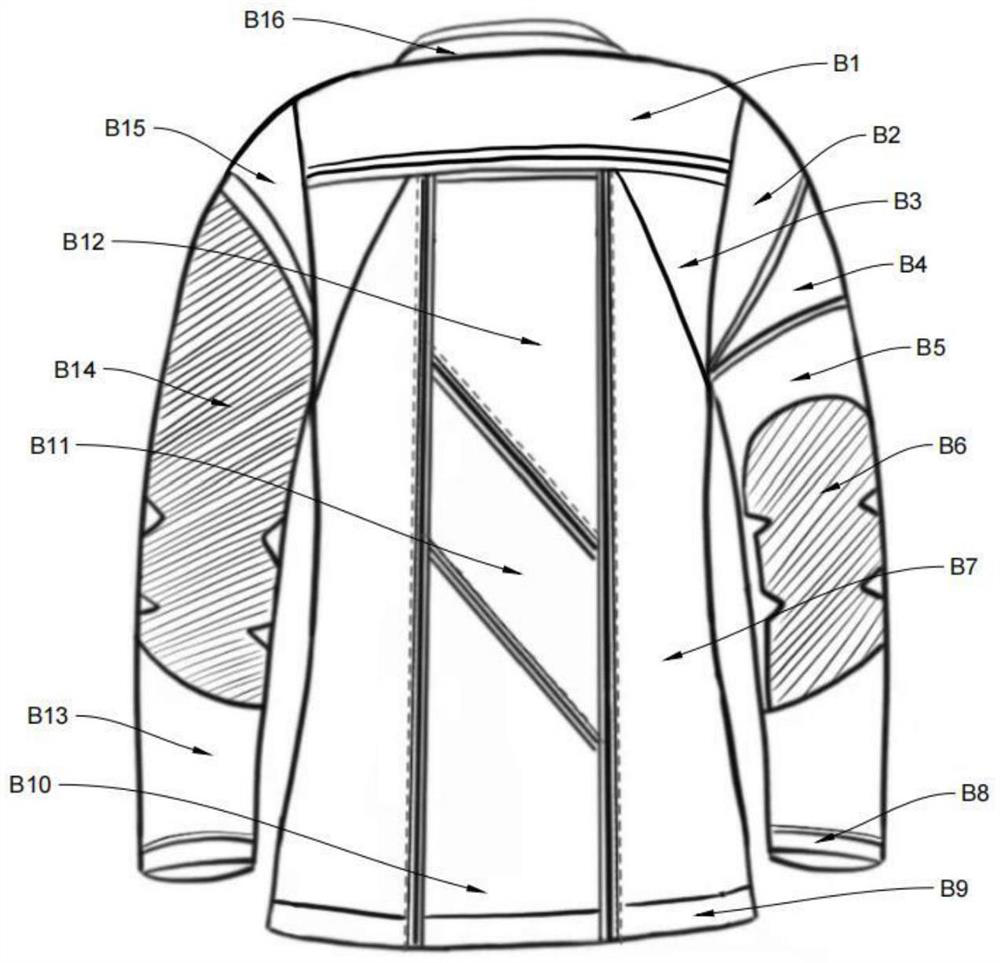

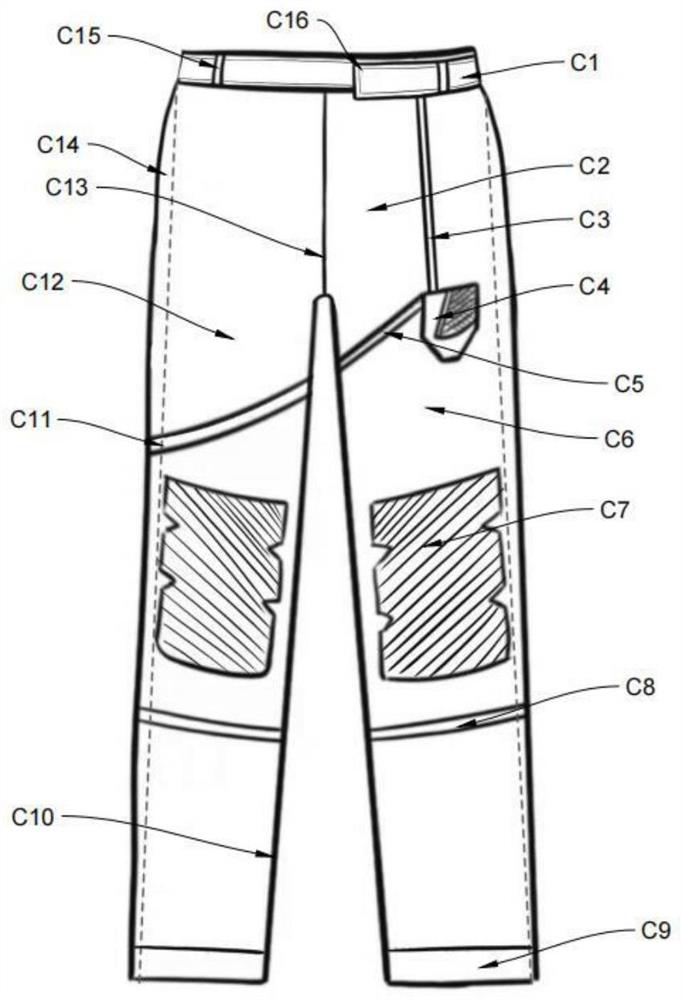

[0039] combined with figure 1 to attach Figure 7 , a frame-type competition rifle shooting functional suit consists of:

[0040] Outerwear jacket, trousers, two major components. The composition materials are canvas, non-slip rubber, leather, support strips (nylon glue sticks with diameters ranging from 2-4 mm), opening and closing zippers, buttons, opening and closing Velcro, elastic cloth, decorative cloth strips, canvas glue, lining Cloth, and other pieces of sewing combined technology;

[0041] Specifically, the jacket includes the front cut piece of the jacket and the back cut piece of the jacket, the trousers include the front cut piece of the trousers and the back cut piece of the trousers, the front cut piece of the jacket is sewn together with the back cut piece of the jacket, and the front cut piece of the trousers is connected with the back cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com