Method for extracting peony seed essential oil based on solvent method

A solvent method and technology of peony, which is applied in the field of extracting the essential oil of peony seeds based on the solvent method, can solve the problems of inability to spread and spread, and achieve the effects of high extraction efficiency, reduction of pine tree mortality, and short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

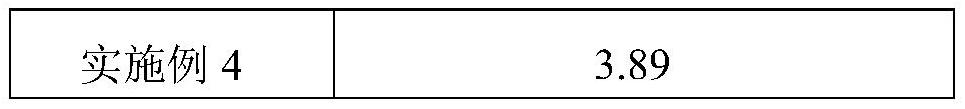

Embodiment 1

[0027] The method for extracting the essential oil of Paeoniae officinalis based on the solvent method described in the present embodiment comprises the following steps:

[0028] (1) Remove impurities from the peony seeds, put them into the sieving equipment, put the sieved peony seeds into the drying equipment, heat them to 66°C for 18 hours, and then put them into the crushing equipment to crush and sieve to obtain about 60 mesh peony seeds, set aside;

[0029] (2) Take 100kg of the above peony seed fragments and place them in a Soxhlet extraction device, and add an organic extraction solvent (the volume ratio of ethyl acetate, ethanol and petroleum ether is 1:2:5) according to the mass ratio of 1:4. Dispersing and soaking for 1 hour, then raising the temperature to 80°C for heat preservation and extraction for 3 hours, collecting the extract containing the crude oil of Paeoniae officinalis, concentrating under reduced pressure, recovering the organic extraction solvent, and...

Embodiment 2

[0033] The method for extracting the essential oil of Paeoniae officinalis based on the solvent method described in the present embodiment comprises the following steps:

[0034] (1) Peony seeds are removed from impurities and put into sieving equipment. The sieved peony seeds are put into drying equipment and heated to 60°C for drying for 18 hours, and then put into crushing equipment to crush and sieve to obtain 50-100 Shredded peony seeds of about 1 mesh, set aside;

[0035] (2) Take 100kg of the above peony seed fragments and place them in a Soxhlet extraction device, and add an organic extraction solvent (the volume ratio of ethyl acetate, ethanol and petroleum ether is 1:2:5) according to the mass ratio of 1:4. Dispersing and soaking for 1 hour, then raising the temperature to 85°C for heat preservation and extraction for 3 hours, collecting the extract containing the crude oil of Paeoniae officinalis, concentrating under reduced pressure, recovering the organic extracti...

Embodiment 3

[0039] The method for extracting the essential oil of Paeoniae officinalis based on the solvent method described in the present embodiment comprises the following steps:

[0040] (1) Remove impurities from the peony seeds, put them into the sieving equipment, put the sieved peony seeds into the drying equipment and heat them to 40°C for sufficient drying, and then put them into the crushing equipment to crush and sieve to obtain about 80 mesh Crushed peony seeds, set aside;

[0041] (2) Take 100kg of the above peony seed fragments and place them in a Soxhlet extraction device, and add an organic extraction solvent (the volume ratio of ethyl acetate, ethanol and petroleum ether is 1:2:5) according to the mass ratio of 1:3. Dispersing and soaking for 1 hour, then raising the temperature to 70°C for heat preservation and extraction for 3 hours, collecting the extract containing the crude oil of Paeoniae officinalis and concentrating under reduced pressure, recovering the organic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com