Preparation method and application of FeSn compound coated NC electrocatalyst

A technology of electrocatalysts and compounds, applied in fuel cell half-cells and secondary battery-type half-cells, circuits, electrical components, etc., can solve the problems of easy poisoning, high price, poor stability, etc., and achieve ORR performance Excellent, large specific surface area, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 7.88 g 2-methylimidazole and 7 g Zn(NO 3 ) 2 ∙6H 2 O was dissolved in 400 mL of methanol, after stirring at room temperature for 30 min, at 60 o After standing at C for 24 h, the obtained product was washed with methanol, centrifuged, and vacuum-dried for 12 h to obtain ZIF-8. Subsequently, 0.61 g Fe(NO 3 ) 3 ∙9H 2 O and 0.36 g (CH 3 COO) 2 Sn was dissolved in methanol in turn, and ZIF-8 was added to soak and stir for 4 h, then centrifuged and washed with methanol, and dried in vacuum for 12 h. Finally, the obtained powder was ground evenly, and placed in the center of the tube furnace, in a high-purity Ar atmosphere at a heating rate of 5 o C / min heating up to 900 o C, High temperature pyrolysis for 2 h to obtain FeSn compound@NC electrocatalyst, labeled as FeSn compound@NC-1.

[0022] figure 1 The FeSn compound @NC-1 in a is the XRD pattern of the catalyst prepared in this example. As shown in the figure, the broad diffraction peak at about 26° corresponds ...

Embodiment 2

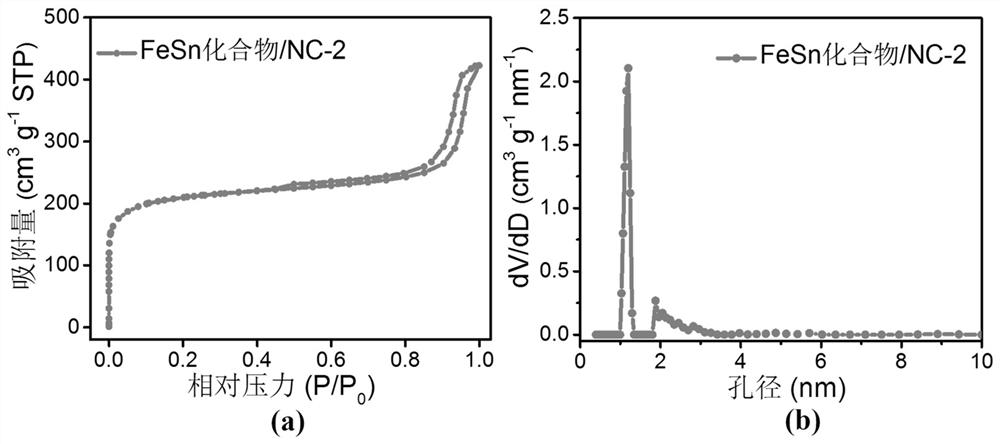

[0024] 7.88 g 2-methylimidazole and 7 g Zn(NO 3 ) 2 ∙6H 2 O was dissolved in 400 mL of methanol, stirred at room temperature for 30 min, and then allowed to stand at 60 °C for 24 h, then the obtained product was washed with methanol, centrifuged, and vacuum-dried for 12 h to obtain ZIF-8. Subsequently, 0.61 g Fe(NO 3 ) 3 ∙9H 2 O and 0.12 g (CH 3 COO) 2 Sn was dissolved in methanol in turn, and ZIF-8 was added to soak and stir for 4 h, then centrifuged and washed with methanol, and dried in vacuum for 12 h. Finally, the obtained powder was ground evenly, and placed in the center of the tube furnace, in a high-purity Ar atmosphere at a heating rate of 5 o C / min heating up to 900 o C, High temperature pyrolysis for 2 h to obtain FeSn compound@NC electrocatalyst, labeled as FeSn compound@NC-2.

[0025] figure 1 The FeSn compound @NC-2 in b is the XRD pattern of the catalyst prepared in this example. Same as Example 1, the broad diffraction peak at around 26° corresponds...

Embodiment 3

[0027] 7.88 g 2-methylimidazole and 7 g Zn(NO 3 ) 2 ∙6H 2 O was dissolved in 400 mL of methanol, stirred at room temperature for 30 min, and then allowed to stand at 60 °C for 24 h, then the obtained product was washed with methanol, centrifuged, and vacuum-dried for 12 h to obtain ZIF-8. Subsequently, 0.61 g Fe(NO 3 ) 3 ∙9H 2 O and 0.12 g (CH 3 COO) 2 Sn was dissolved in methanol in turn, and ZIF-8 was added to soak and stir for 4 h, then centrifuged and washed with methanol, and dried in vacuum for 12 h. Finally, the obtained powder was ground evenly, placed in the center of a tube furnace, heated to 1000 °C in a high-purity Ar atmosphere at a heating rate of 5 °C / min, and pyrolyzed at a high temperature for 2 h to obtain the FeSn compound@NC electrocatalyst, marked is the FeSn compound @NC-3.

[0028] figure 1 The FeSn compound @NC-3 in c is the XRD pattern of the catalyst prepared in this example. It is the same as Example 1 and 2, with a wider diffraction peak at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com