Gas waste heat recovery and purification device and system thereof

A waste heat recovery and purification device technology, applied in preheating, steam condensation, lighting and heating equipment, etc., can solve problems such as energy waste, low steam utilization rate, and affecting the normal production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

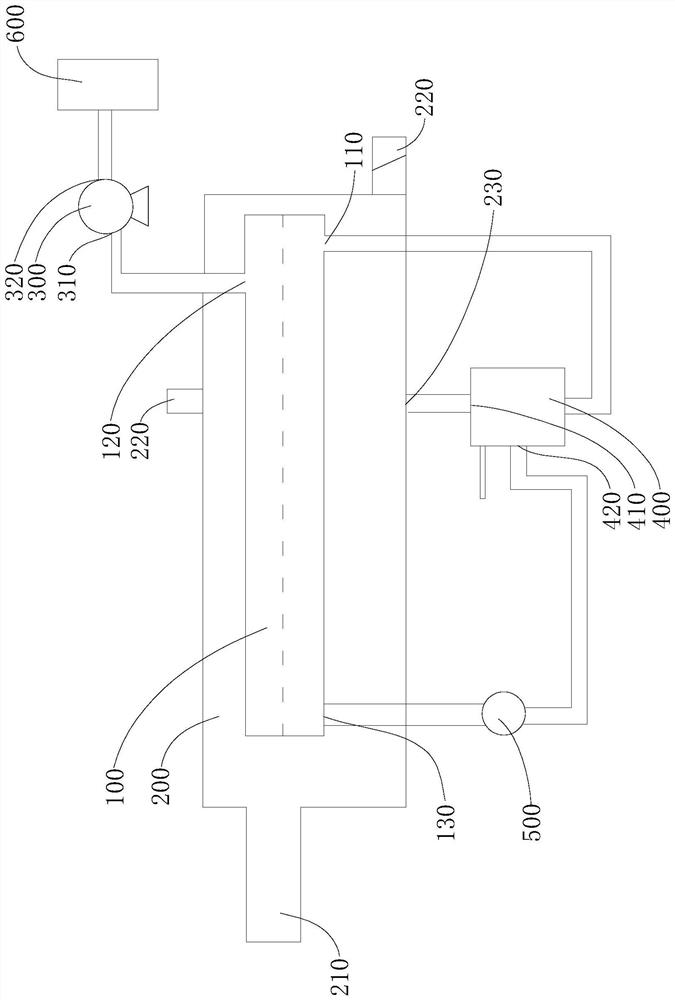

[0037] Embodiment one, see figure 1 , The embodiment of the present invention provides a gas waste heat recovery and purification device, including: an evaporation chamber 100 , a condensation chamber 200 , an air extraction device 300 and a condensed water collector 400 .

[0038] Among them, the condensation chamber 200 is provided with a first air inlet 210, a second air outlet 220 and a first water outlet 230, and EPP (polypropylene plastic foam material) and EPS (polystyrene foam) in the packaging industry are foamed The molding equipment will generate more exhaust air, and the exhaust air itself has a certain temperature, and the exhaust air can pass into the condensation chamber 200 from the first air inlet 210 .

[0039] The evaporation chamber 100 is provided with a first water inlet 110 and a first exhaust port 120, and the air extraction device 300 communicates with the first exhaust port 120, and the air extraction device 300 can perform air extraction on the evapo...

Embodiment 2

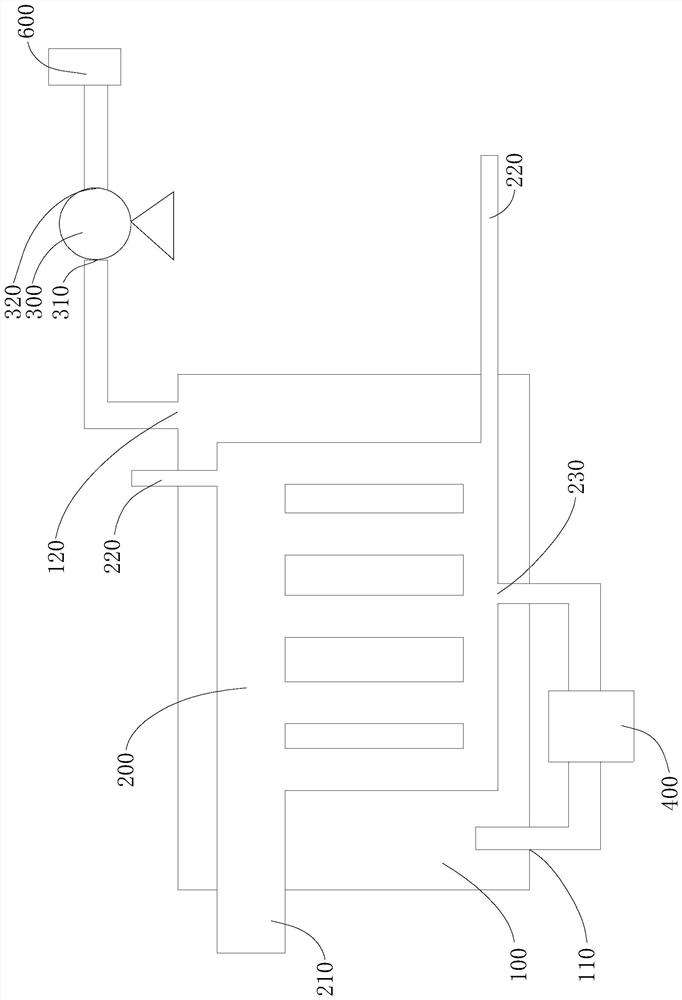

[0074] Embodiment two, see figure 2 , the embodiment of the present invention also provides a gas waste heat recovery and purification device, including: an evaporation chamber 100, a condensation chamber 200, an air extraction device 300 and a condensed water collector 400, wherein the structures of the evaporation chamber 100 and the condensation chamber 200 are the same as The first embodiment is roughly the same, the main difference is that the evaporation chamber 100 can be arranged around the outside of the condensation chamber 200, which is beneficial to increase the connecting area between the condensation chamber 200 and the evaporation chamber 100, that is, to increase the heat exchange area between the two, and also to It is beneficial to realize the comprehensive heat exchange between the condensation chamber 200 and the evaporation chamber 100. The junction of the condensation chamber 200 and the evaporation chamber 100 shares the same wall surface, that is, the m...

Embodiment 3

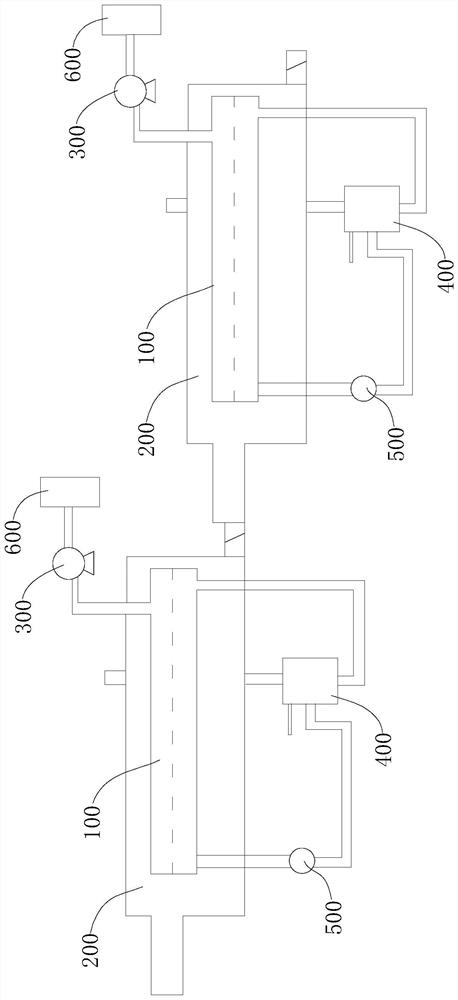

[0076] Embodiment three, see image 3 , the embodiment of the present invention also provides a exhaust gas waste heat recovery and purification system, including: a plurality of gas waste heat recovery and purification devices as provided in Embodiment 1 or Embodiment 2, and a plurality of gas waste heat recovery and purification devices are arranged in an array And connected in sequence.

[0077] In order to further recover the waste heat of exhaust gas, the waste heat recovery and purification system of exhaust gas is equipped with multiple gas waste heat recovery and purification devices, which are connected in sequence through multiple gas waste heat recovery and purification devices, so as to realize the function of waste heat recovery of exhaust gas step by step .

[0078] In the exhaust gas waste heat recovery and purification system, the pressure in the evaporation chamber 100 of the gas waste heat recovery and purification device located at the rear and the boiling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com