Powder coating and preparation method thereof

A powder coating and fiber technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as poor compatibility and shortened service life of coatings, and achieve high uniformity, extended service life, and good activation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

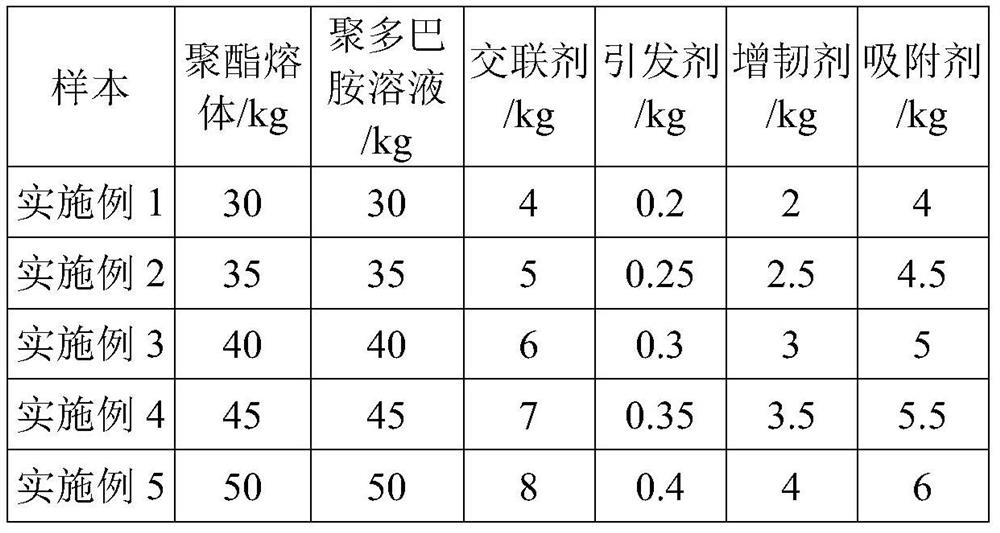

Examples

preparation example 1

[0047] In this preparation example, the adsorbent is prepared according to the following method:

[0048] (1) 40kg natural zeolite powder, 40kg glycerol, 160kg lithium hydroxide solution are mixed uniformly to obtain mixed solution 1; in this step, the pH of mixed solution 1 is 10;

[0049] (2) Add 8kg of hydroxymethyltriethoxysilane and 8kg of vinyltriethoxysilane to the mixed solution 1, stir evenly and heat to 60°C to obtain the mixed solution 2;

[0050] (3) Remove the liquid component in the mixed liquid 2, grind the remaining solid component, and then screen the powder with a particle size between 350-550 μm to obtain the adsorbent.

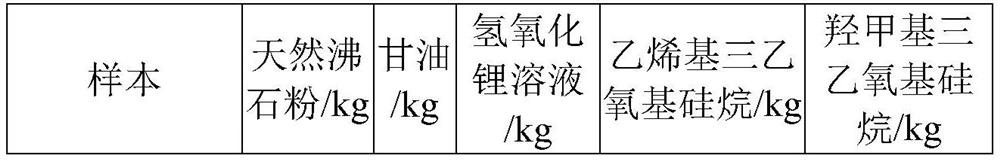

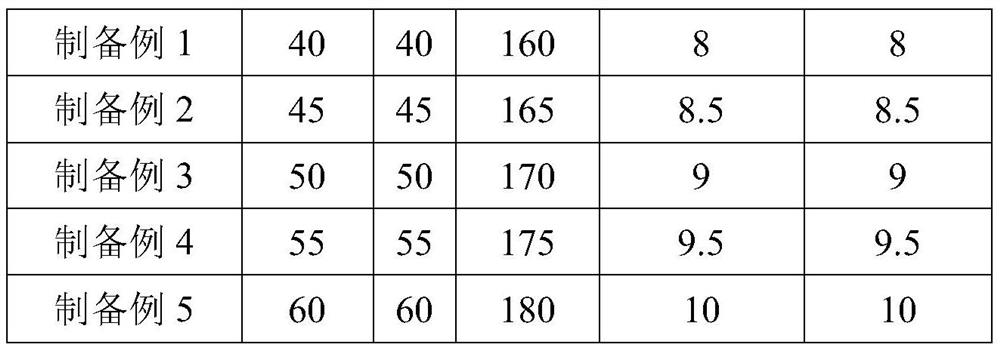

[0051] As shown in Table 1, the difference between Preparation Examples 1-5 is that the ratio of raw materials is different.

[0052] Table 1

[0053]

[0054]

preparation example 6

[0056] The difference between this preparation example and preparation example 3 is that the pH of the mixed solution 1 is 8.

preparation example 7

[0058] The difference between this preparation example and preparation example 3 is that the pH of the mixed solution 1 is 12.

[0059] Preparation example of nanocellulose whiskers

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com