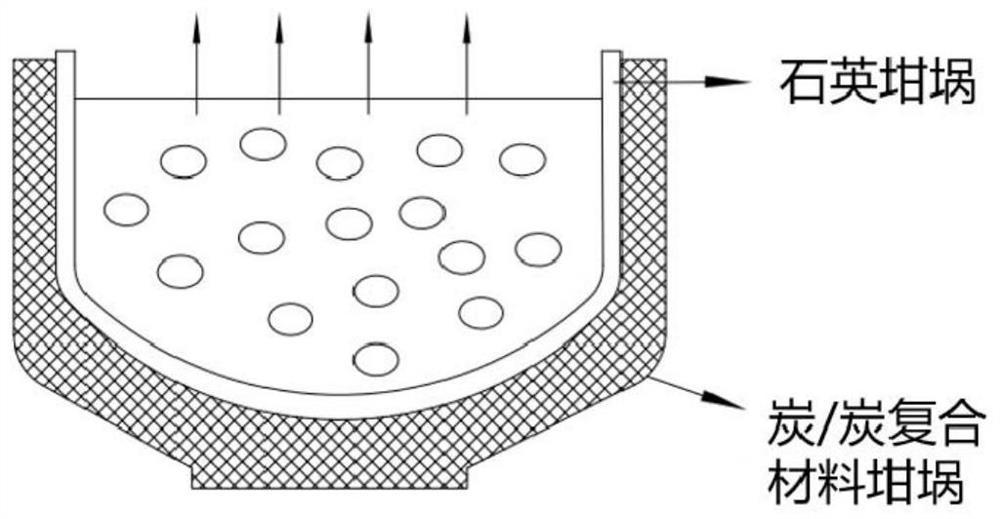

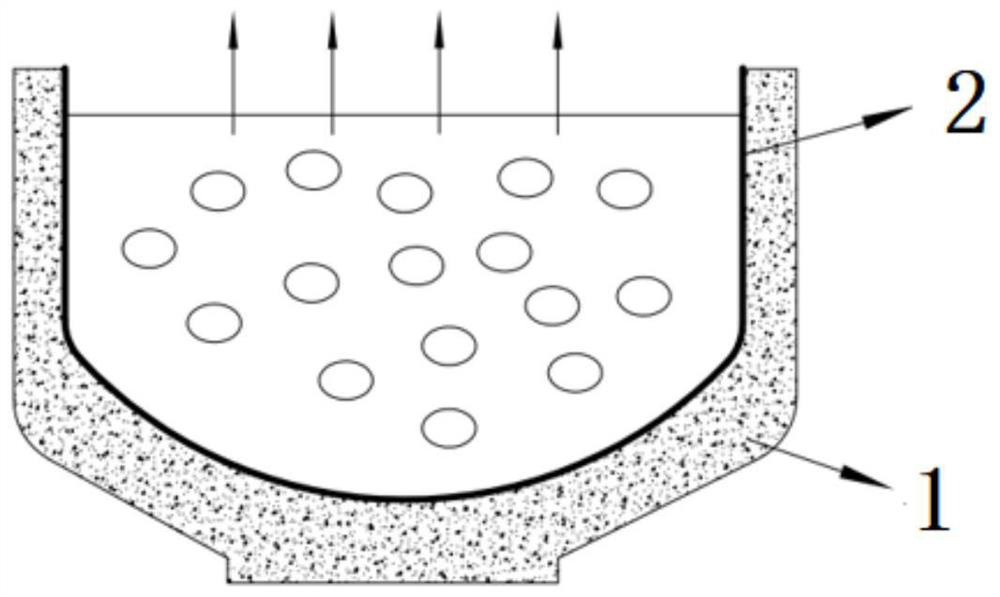

C/SiC composite material crucible containing alpha-Al2O3 coating

A composite material and crucible technology is applied in the field of thermal field components for single crystal silicon drawing furnaces, which can solve the problems of not playing a substitute role, shortening the service life of the crucible, poor thermal shock resistance, etc., achieving significant economic benefits, avoiding mechanical Good damage and crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A containing α-Al 2 o 3 The preparation steps of the coated C / SiC composite crucible are as follows:

[0029] (1) The bulk density is 0.40g / cm3 prepared in the form of axial carbon fiber non-weft cloth / carbon mesh tire composite layup and circumferential carbon fiber continuous winding layer alternately stacked and needle punched 3 carbon fiber prefabricated body;

[0030] Among them, the carbon fiber non-weft cloth / carbon mesh tire composite layer contains a layer of carbon fiber non-weft cloth and a layer of carbon mesh tire, and the carbon fiber non-weft cloth / carbon mesh tire composite layer and a layer of carbon fiber continuous winding layer Alternate superposition;

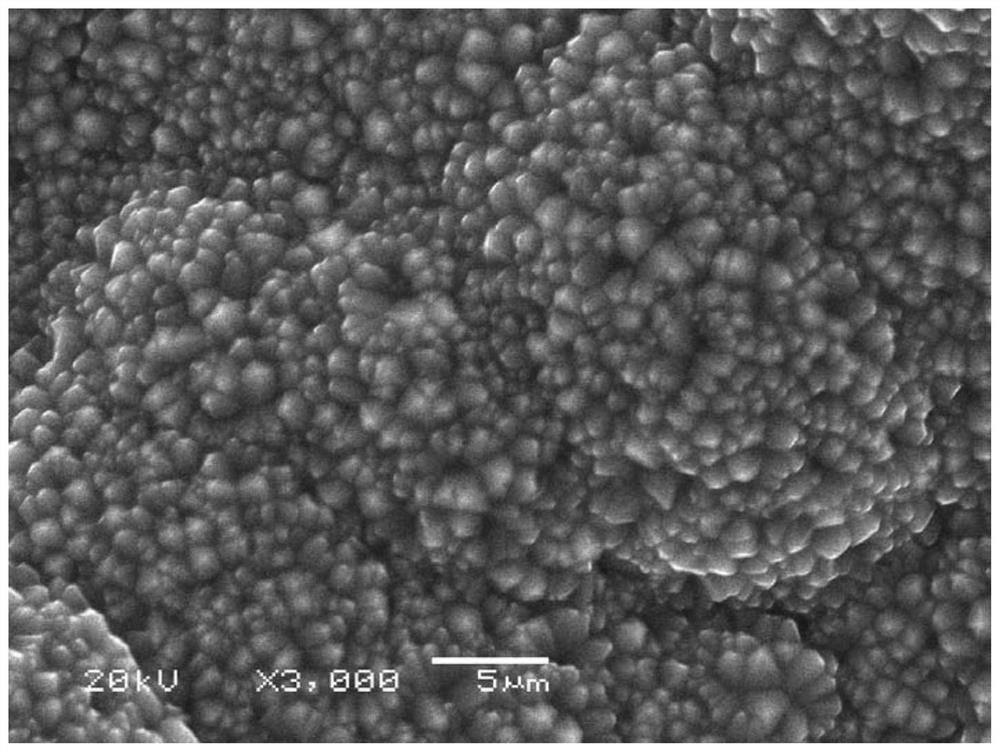

[0031] (2) Place the carbon fiber preform in a chemical vapor deposition furnace, use trichloromethylsilane as the silicon source gas, the flow rate of the silicon source gas is 10L / min, the deposition temperature is 1100°C, and the single deposition time is 300h. Carried out 5 times of chemical ...

Embodiment 2

[0036] A containing α-Al 2 o 3 The preparation steps of the coated C / SiC composite crucible are as follows:

[0037] (1) The bulk density is 0.50g / cm3 prepared in the form of alternate superposition of axial carbon fiber non-woven fabric / carbon mesh tire composite layer and circumferential carbon fiber continuous winding layer. 3 carbon fiber prefabricated body;

[0038] Among them, the carbon fiber non-weft cloth / carbon mesh tire composite layer contains a layer of carbon fiber non-weft cloth and a layer of carbon mesh tire, and the carbon fiber non-weft cloth / carbon mesh tire composite layer and a layer of carbon fiber continuous winding layer Alternate superposition;

[0039] (2) Place the carbon fiber preform in a chemical vapor deposition furnace, use trichloromethylsilane as the silicon source gas, the flow rate of the silicon source gas is 30L / min, the deposition temperature is 1200°C, and the single deposition time is 200h. Perform 3 chemical vapor depositions to o...

Embodiment 3

[0044] A containing α-Al 2 o 3 The preparation steps of the coated C / SiC composite crucible are as follows:

[0045] (1) The bulk density is 0.60g / cm3 prepared in the form of axial carbon fiber non-weft cloth / carbon mesh tire composite layup and circumferential carbon fiber continuous winding layer alternately stacked and needle punched 3 carbon fiber prefabricated body;

[0046] Among them, the carbon fiber non-weft cloth / carbon mesh tire composite layer contains a layer of carbon fiber non-weft cloth and a layer of carbon mesh tire, and the carbon fiber non-weft cloth / carbon mesh tire composite layer and a layer of carbon fiber continuous winding layer Alternate superposition;

[0047] (2) Place the carbon fiber preform in a chemical vapor deposition furnace, use trichloromethylsilane as the silicon source gas, the flow rate of the silicon source gas is 50L / min, the deposition temperature is 1300°C, and the single deposition time is 150h. Perform 2 chemical vapor deposit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com