Crack measurement endoscope

A technology for endoscopes and cracks, which can be used in measuring devices, optical testing of flaws/defects, image enhancement, etc., and can solve problems such as low illumination and inability to measure crack length and width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0122] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

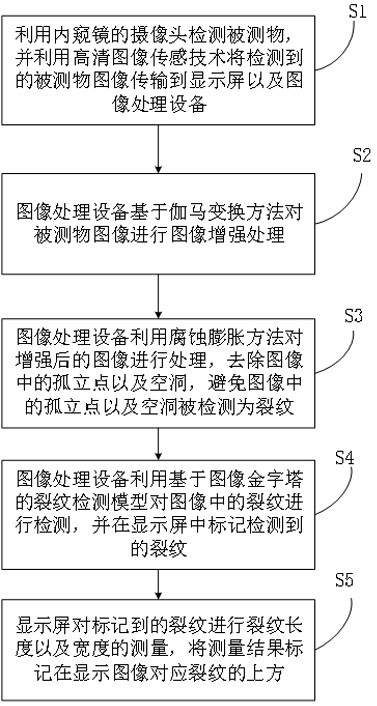

[0123] S1: Use the camera of the endoscope to detect the object under test, and use high-definition image sensing technology to transmit the image of the detected object to the display screen and image processing equipment.

[0124] In the S1 step, the camera of the endoscope is used to detect the measured object, including:

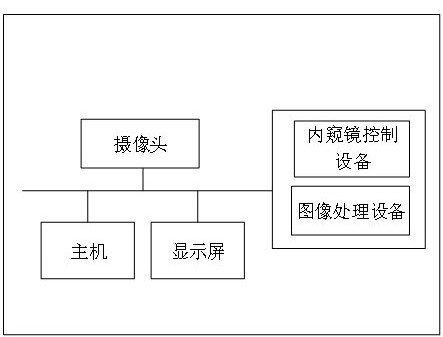

[0125] Use the endoscope control equipment in the endoscope detection system to control and select the camera or video function of the endoscope, and control the light intensity of the endoscope camera to capture a static image or dynamic video of the object under test. The diameter of the probe is Φ8mm, the pixel is 1 million, the depth of field is 8-80mm, and the viewing direction is direct view; At the same time, the image processing equipment in the endoscope inspection system measures the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com