Method for identifying blade cracks of wind driven generator

A technology for cracks in wind turbines and blades, which is applied in the monitoring of wind turbines, wind turbines, engines, etc. It can solve the problems of insufficient clarity of tiny cracks, long space distance, and the need to improve the accuracy of visual recognition of blade cracks. Low cost, easy implementation, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

[0029] The identification method of the wind generator blade crack of the present invention comprises:

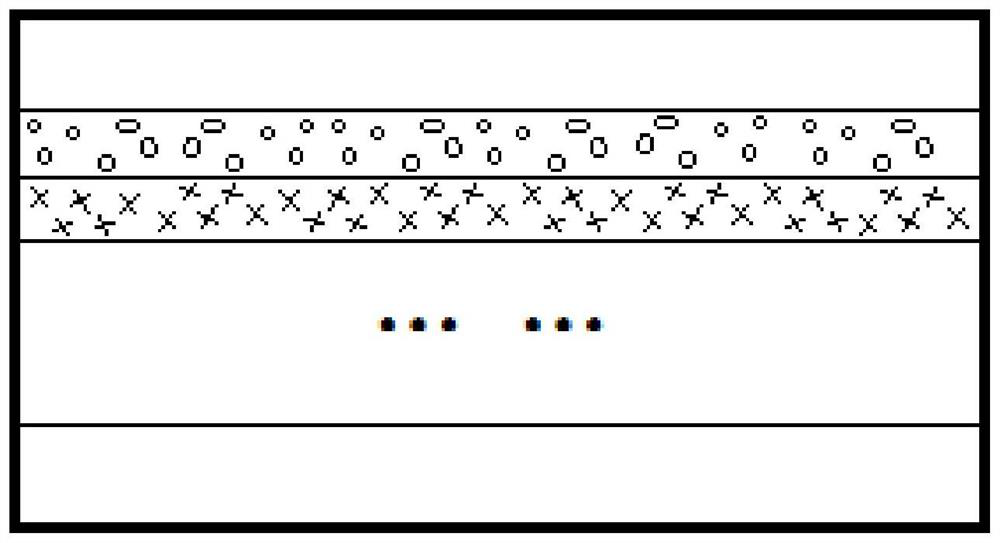

[0030] S1: During the blade manufacturing process, the second layer of composite material adjacent to the blade surface layer is colored with a colorant before laying up the layer, and the coloring is different from the color of the blade surface layer;

[0031] S2: In the process of blade transportation and hoisting, the surface of the blade is inspected visually; when the wind turbine is running, the surface of the blade is detected by using the UAV to collect image information of the blade surface; when the wind turbine is shut down, use the telescope to visually inspect Or the UAV collects the image information of the blade surface to detect the blade surface; when it is found tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com