In-situ test equipment for laser thermal shock test of accelerated life of coating

An accelerated life and in-situ testing technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem that the real-time observation and recording of sample coating cracks cannot be performed, and the thermal shock equipment cannot accurately obtain the surface temperature of the heated sample coating And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

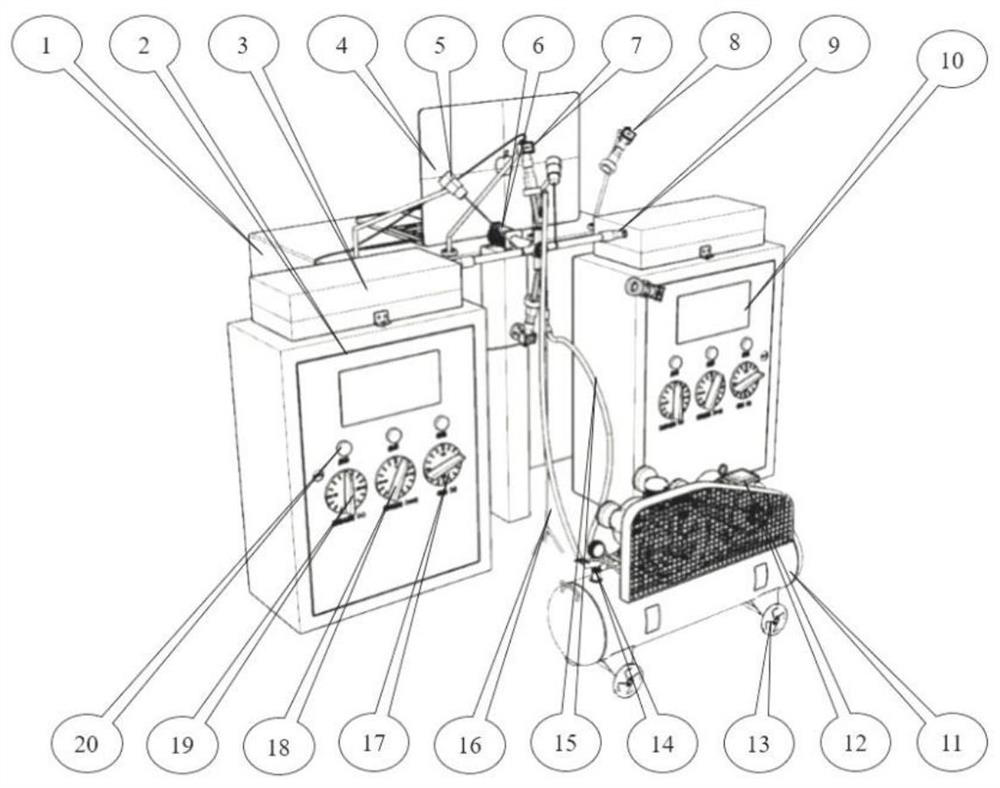

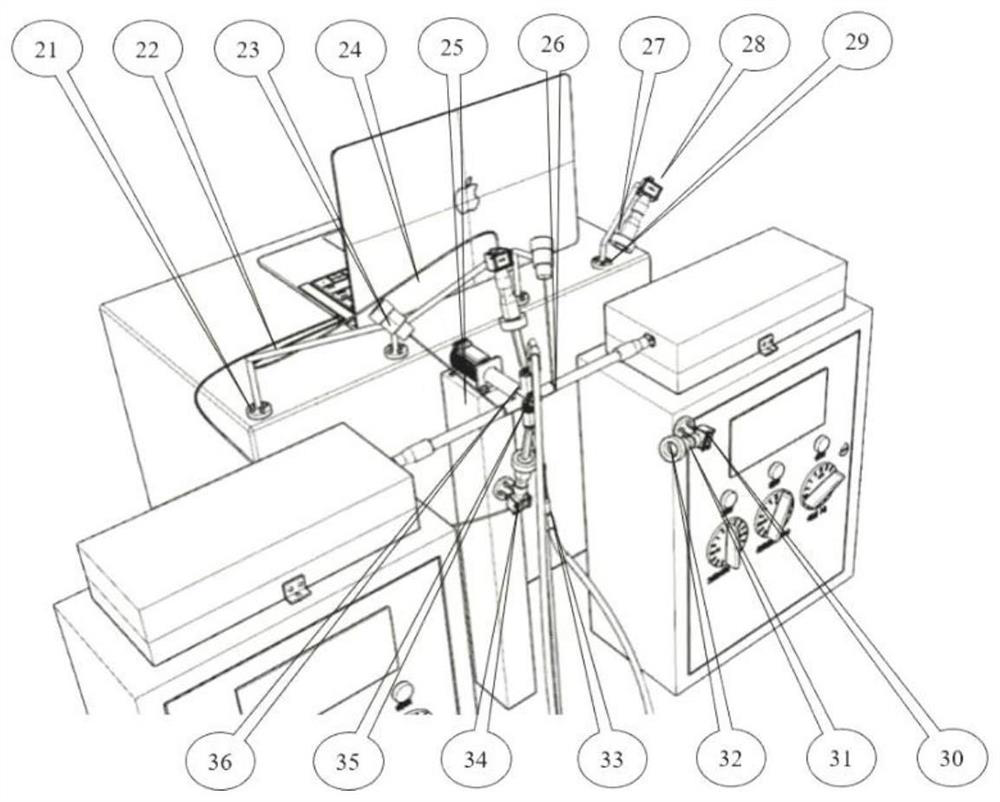

[0035] Such as figure 1 , 2 As shown, an in-situ test equipment for accelerated life laser thermal shock test of the present invention includes a laser generator and a control system, a cooling system, a temperature measurement system, an in-situ observation system, a machine clamp system and a control module. Among them, the laser generator and control system solve all the shortcomings caused by flame heating, and achieve the effect of rapid and precise temperature rise on the sample coating. Its components include: pump source, glass optical fiber, resonant cavity, quasi- Straight optical system, flat-top light shaper 9, casing part 3, power control cabinet 2. The cooling system realizes the function of fully reducing the service condition of the sample coating, and its components include: an air compressor 12, a universal wheel 13 with a self-locking function, an air storage tank 11, an air hose 15, a flow rate Control valve 14, position-adjustable chuck, and triangular ...

Embodiment 2

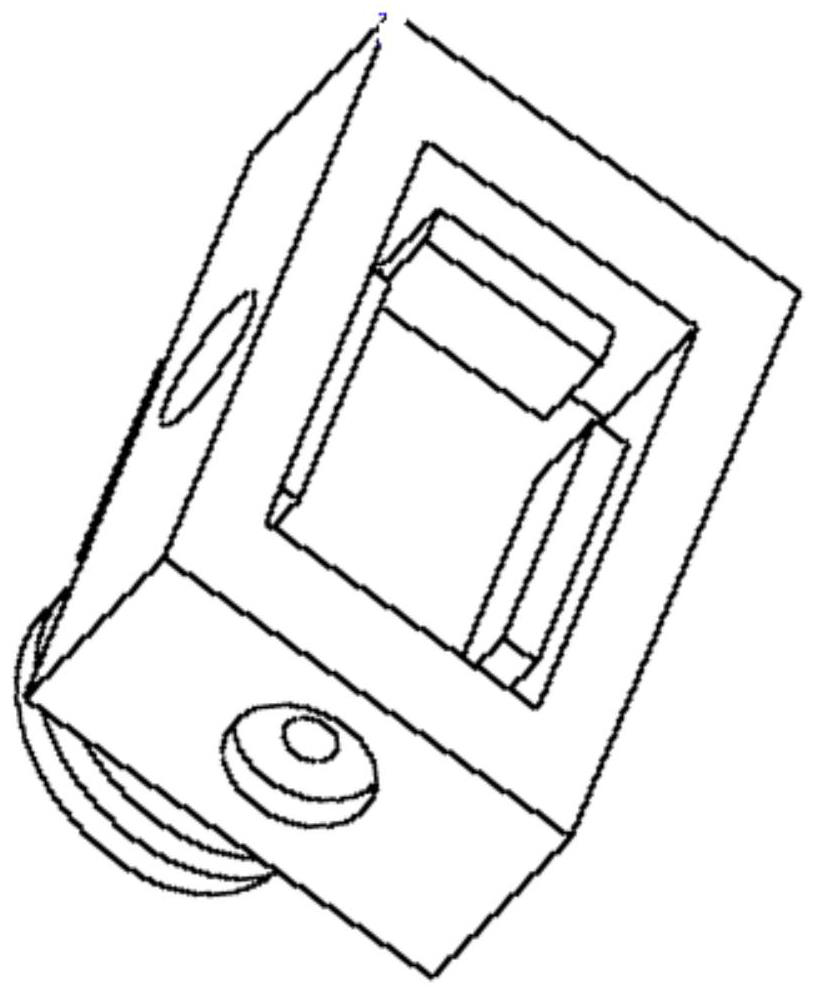

[0047] Such as image 3 As shown, the square sample holder of the present invention is disclosed, which is composed of three parts: a quadrangular clamp body, a clamping bolt (×4), and a rectangular pressing plate (×4); as Figure 4 As shown, it is a circular workpiece fixture, which consists of three parts: a cylindrical clamp body, a clamping bolt (×3), and an arc-shaped pressure plate (×3). A detachable connection is formed between the external thread of the bottom protruding part of the two sets of clamping devices and the internal thread of the rotating cross shaft.

[0048] The advantage of the above-mentioned device: since the sample holder and the rotating cross shaft are detachably connected, the experimental device has diversity in the selection of samples.

[0049] After adopting the square sample fixture, the test steps are as follows:

[0050] Step 1: Select the appropriate sample fixture according to the shape and size of the sample to be tested, adjust the tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com