Efficient release paper automatic drying and conveying system

A conveying system and release paper technology, which is applied in drying, drying machines, progressive dryers, etc., can solve the problem of inconvenient control of the release paper residence time, different internal temperatures of the drying box, and uneven heating and other issues, to achieve the effect of increasing heat dissipation, increasing quality, and facilitating conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

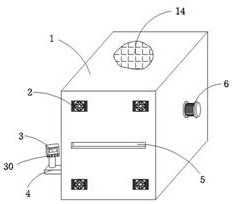

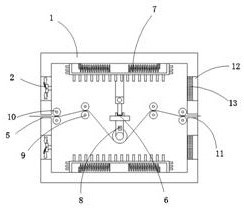

[0030] This embodiment is a high-efficiency automatic drying and conveying system for release paper.

[0031] Such as Figure 1-5 As shown, including drying case 1, the middle part of the outer surface of one end of drying case 1 is provided with a discharge port 5, the middle part of the outer surface of the other end of drying case 1 is provided with a feed port 11, and the middle part of the outer surface of one end of drying case 1 is provided with a feed port 11. The four corners are equipped with fan 2, the four corners of the outer surface of the other end of the drying box 1 are provided with an air inlet 12, the left and right ends of the upper and lower sides of the inner cavity of the drying box 1 are fixedly installed with heating components 7, and the inner cavity of the drying box 1 An adjustment assembly 6 is arranged in the middle, and a temperature sensor 8 is fixedly installed on the outer wall of the lower part of the adjustment assembly 6. A first mounting ...

specific Embodiment 2

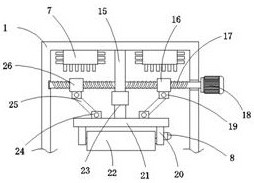

[0035] This embodiment is an embodiment of the adjustment component 6 in the high-efficiency release paper automatic drying and conveying system.

[0036] Such as figure 1 , 2 , 3, an adjustment assembly 6 for an efficient release paper automatic drying conveying system, the adjustment assembly 6 includes a mounting rod 15, a first ball nut 16, a ball screw 17, a positive and negative motor 18, and a first connecting block 19. Side plate 20, second mounting plate 21, adjusting roller 22, telescopic rod 23, first mounting plate 4, movable rod 25 and second ball nut 26, and positive and negative motor 18 is fixedly installed on one side of drying box 1 On the outer surface, the ball screw 17 is located on the outer surface of one end of the positive and negative motor 18, the mounting rod 15 is located on the outer wall of the middle part of the ball screw 17, and the upper end outer surface of the mounting rod 15 is fixedly connected to the inner wall of the drying box 1, and ...

specific Embodiment 3

[0038] This embodiment is an embodiment of the heating assembly 7 in the high-efficiency release paper automatic drying and conveying system.

[0039] Such as figure 2 , 3 , 4, and 5, a heating assembly 7 for a high-efficiency release paper automatic drying and conveying system, the number of heating assemblies 7 is four groups, and the heating assembly 7 includes a pure copper box 27, cooling fins 28 and heating wires 29 , and the output end of the control switch 30 is electrically connected to the input end of the controller 3, the output end of the controller 3 is electrically connected to the input end of the temperature sensor 8, and the output end of the controller 3 is connected to the heating The input ends of the wires 29 are electrically connected; the heating wires 29 are fixedly mounted on the left and right sides of the pure copper box 27, and the cooling fins 28 are fixedly mounted on the outer wall of the pure copper box 27.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com