Steel structure composite floor and construction method thereof

A combination of floor slab and construction method technology, applied in the direction of floor slabs, building components, building structures, etc., can solve problems such as unreliable connection between profiled steel plates and steel beams, and achieve green construction, simple production, improved structural stability and safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing: According to following description, advantage and feature of the present invention will be clearer. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

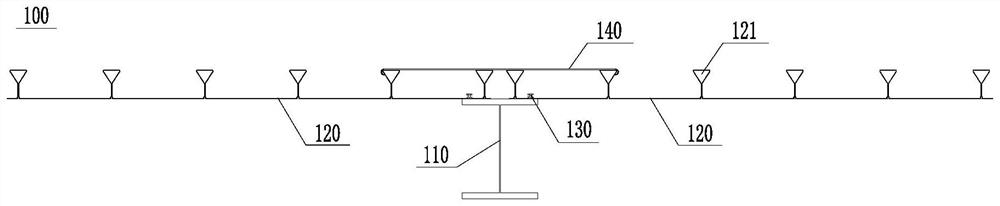

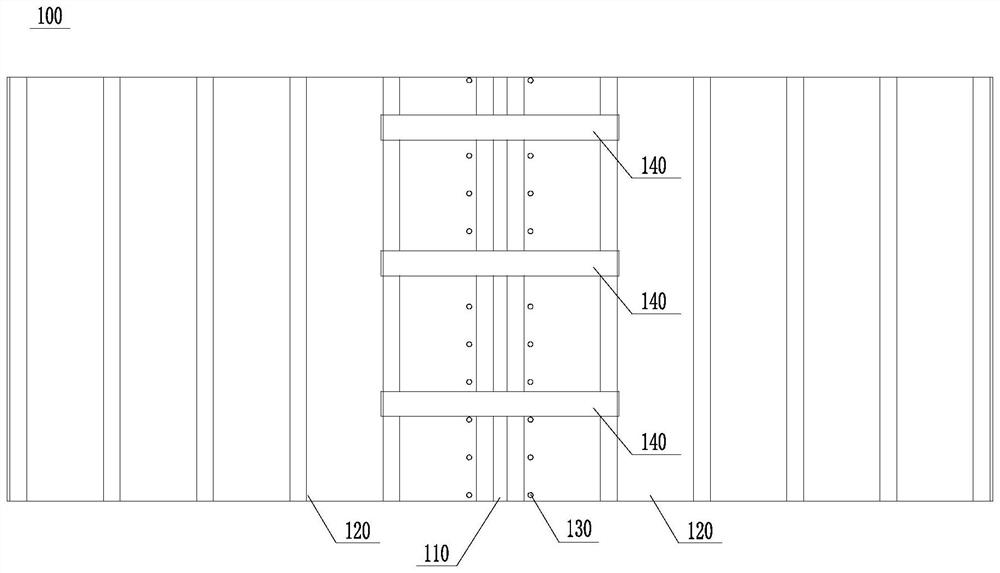

[0036] Please refer to Figure 1 to Figure 2 , the embodiment of the present invention provides a steel structure composite floor 100, including:

[0037] A steel beam 110; wherein the steel beam 110 can be a section steel such as I-beam or channel steel.

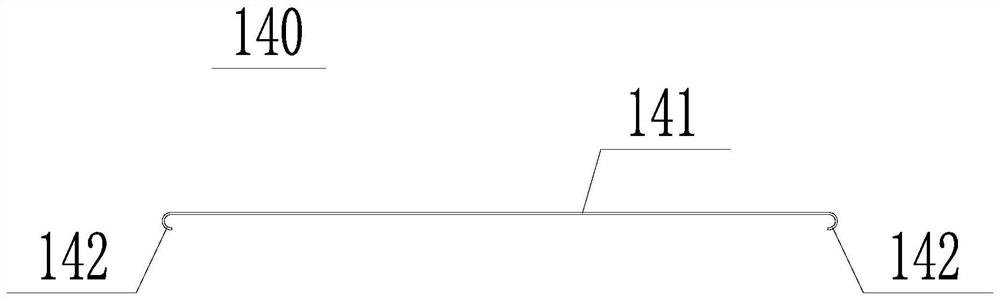

[0038] There are two profiled steel plates 120, which are symmetrically overlapped on the steel beam 110, and each profiled steel plate 120 has a plurality of upwardly protruding back plates 121.

[0039] The peg 130 is connected between the profiled steel plate 120 and the steel beam 110 to connect the profil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com