Catalyst for producing furoic acid through electro-catalytic oxidation of furfural and preparation method and use method of catalyst

A catalyst and electrocatalysis technology, applied in the direction of electrolytic organic production, electrodes, electrolytic components, etc., can solve the problems of practical application discount, high cost of catalytic oxidation, poor stability, etc., and achieve simple process, excellent electrocatalytic furfural oxidation activity and stability sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

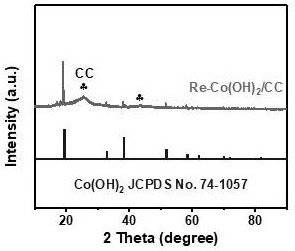

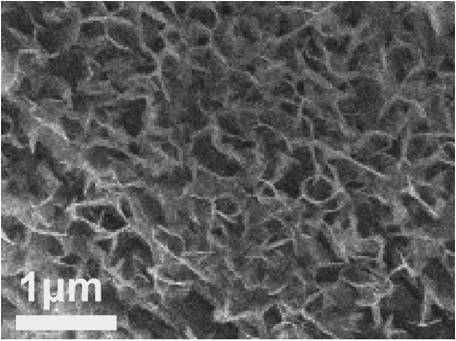

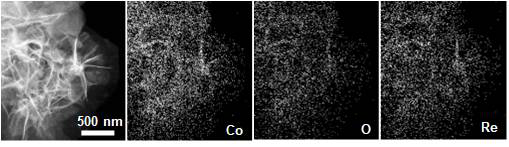

[0025] A Re-Co(OH) for the electrocatalytic oxidation of furfural to produce furoic acid 2 / CC catalyst, the preparation steps are as follows:

[0026] (1) Commercial carbon cloth (Carbon cloth, abbreviated as CC) is pickled and dried after cutting;

[0027] (2) Stir together 3.0 mmol of cobalt nitrate hexahydrate, 0.1 mmol of ammonium perrhenate, 2 mL of 1M hydrochloric acid solution, 3 g of urea, and 30 mL of 2 mol / L ethanol aqueous solution;

[0028] (3) Transfer the mixed solution to a hydrothermal kettle, and at the same time place a piece of water with an area of 3cm 2 Put the carbon cloth in the hydrothermal kettle, tighten the lid of the kettle, and transfer the hydrothermal kettle to the oven;

[0029] (4) Set the oven heating temperature to 150°C and the heating time to 800min;

[0030] (5) Cool the oven to room temperature, open the kettle, take out the carbon cloth, and dry it to get Re-Co(OH) 2 / CC Catalyst.

Embodiment 2

[0032] The difference from Example 1 is that in step (2), the amount of ammonium perrhenate is changed to 0.5 mmol; the others are the same as in Example 1.

Embodiment 3

[0034] The difference from Example 1 is that in step (2), the amount of ammonium perrhenate is changed to 1.0 mmol; the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com