Scratch resistant coating for glass ceramic cooktops

A technology for coating and coating substrates, applied in the direction of coatings, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as hardness reduction, and achieve the effect of reducing mechanical or chemical erosion, transparency and uniform appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

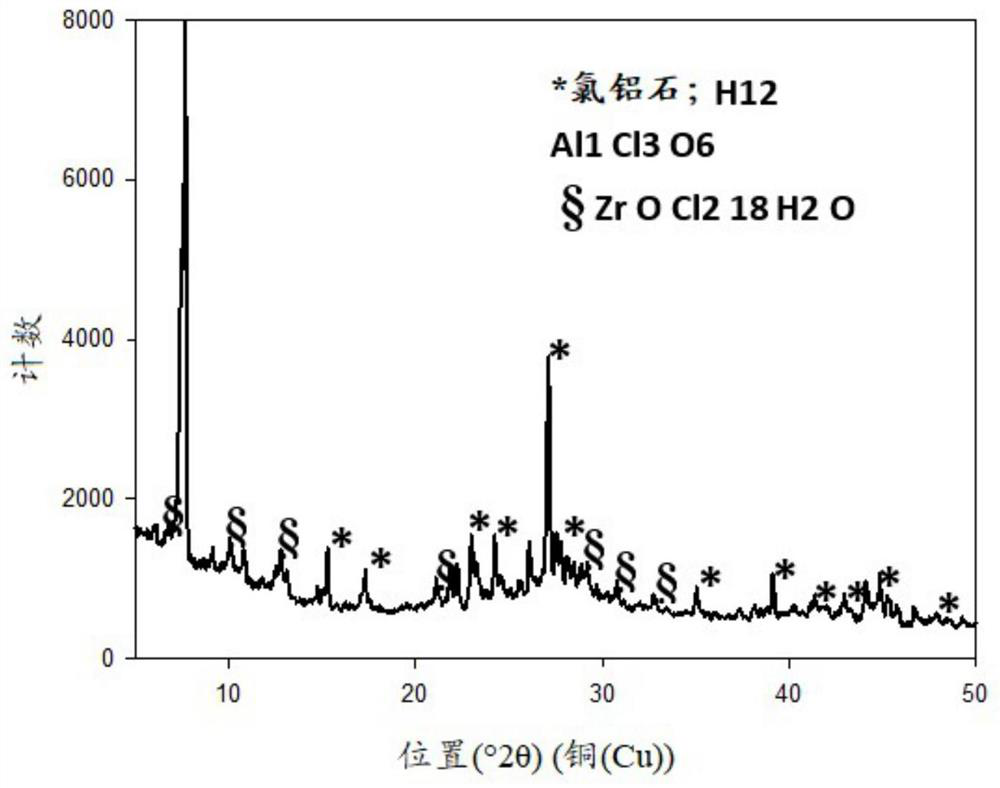

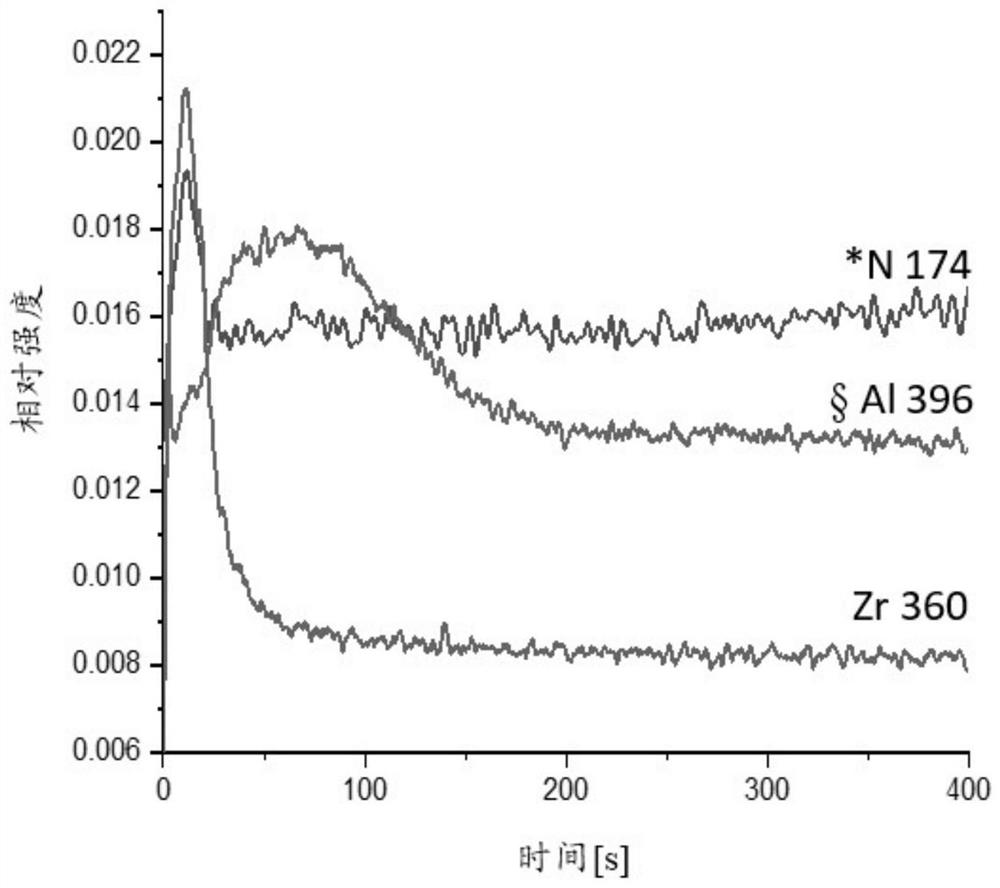

Embodiment 1

[0133] After dissolving 0.1 mol of metal precursors (aluminum chloride and zirconium chloride) and 0.2 mol of nitrogen carrier (guanidine) in ethanol at room temperature of 26° C. under nitrogen flow for 15 hours, a sol with R=2 was obtained. The sol is transparent and has a shelf life of 10 months. Transparent glass-ceramic substrates (7x3 cm) have been impregnated (at 150mm*min -1 The immersion speed of immersion once) is coated by sol. After immersion, the substrate was heated in an oven at 850°C for 1 hour. The coating is transparent with no rainbow effect. A scratch test by Erichsen hardness pencil tester showed a hardness of 11N.

Embodiment 2

[0135] After dissolving 0.1 mol of metal precursors (aluminum sec-butoxide and zirconium chloride) and 0.5 mol of nitrogen carrier (urea) in isopropanol for 20 min under magnetic stirring at 600 rpm, a sol with R=5 was obtained. The sol is clear and has a shelf life of 2 weeks. The black glass-ceramic substrate (7x3 cm) has been impregnated (at 150mm*min -1 The immersion speed of immersion once) is coated by sol. After immersion, the substrate was heated in an oven at 800 °C for 2 hours. Coating results contain an opaque finish. Scratch test by pencil hardness according to ASTM D 3363 showed a value >9H.

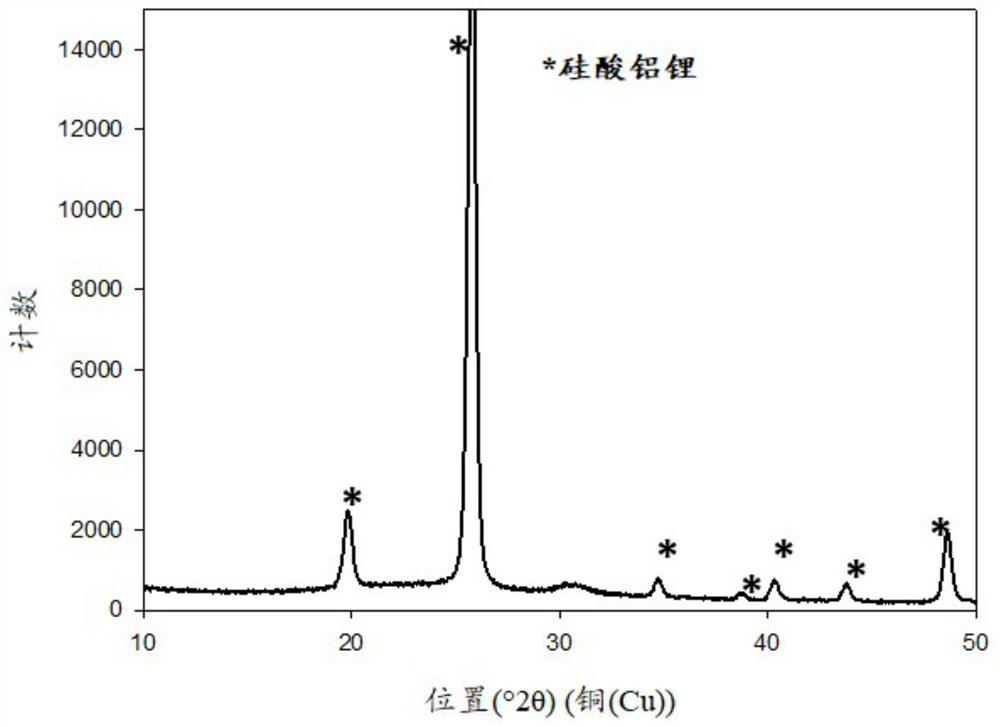

Embodiment 3

[0137] A sol with R=2 was obtained after dissolving 0.1 mol of metal precursors (aluminum chloride and zirconium chloride) and 0.2 mol of nitrogen carrier (urea) in ethanol. The sol is transparent and has a shelf life of six months. Black glass-ceramic substrates (23x27 cm 2 ). The substrate was then heated in an oven at 800°C for 2 hours. Scratch test of opaque finish by Erichsen hardness pencil tester Non-uniform coating results show a hardness of 10N. A cleanability test has been performed by placing 5 grams of tomato paste on the coated glass-ceramic and heating it at 350°C for 15 minutes and then allowing it to cool before the cleaning step. Using a damp soft sponge, apply 100g / cm 2 pressure, to remove cooked food on coated glass-ceramic, showed that 600 strokes (one stroke is considered a back and forth movement) were required to clean at least 95% of the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com